Polyurethane asphalt concrete as well as preparation method and application thereof

An asphalt concrete and polyurethane technology, applied in the field of asphalt concrete, can solve the problems of poor road performance, unsatisfactory performance, environmental pollution, etc., and achieve the effects of prolonging the service life, reducing the emission of toxic and harmful gases, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

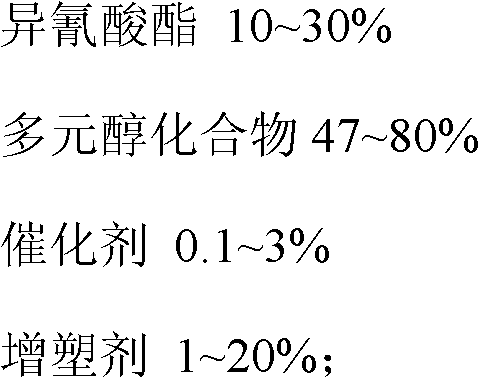

Method used

Image

Examples

Embodiment 1

[0029] A kind of polyurethane bituminous concrete is prepared according to the following steps:

[0030] Add 90kg of polyether diol (molecular weight 1000) into the reaction kettle, the temperature in the kettle is 100-120°C, after vacuum dehydration for 2-3 hours, cool down to 60-70°C, add 18kg of polymethylene polyphenyl polyisocyanate, 0.24kg of dibutyltin dilaurate (DBDTL), 12kg of dioctyl phthalate (DOP), under the condition of nitrogen protection, react at 80-90°C for 4h and cool to about 60°C to prepare polyurethane prepolymer body.

[0031] After heating 60kg of road petroleum asphalt (70#) to melting, mix it with 60kg of gasoline and stir evenly to obtain diluted asphalt.

[0032] Select 1.6t of basalt fine aggregate and 2.4t of basalt coarse aggregate (the nominal particle size of the coarse aggregate is 4.75mm<Φ≤9.5mm, the nominal particle size of the fine aggregate is Φ<4.75mm), and set aside. Mix the prepared diluted asphalt with polyurethane prepolymer, and sti...

Embodiment 2

[0034] A kind of polyurethane bituminous concrete is prepared according to the following steps:

[0035] Add 72kg polyethylene glycol (molecular weight 400) into the reaction kettle, the temperature in the kettle is 100-120°C, after vacuum dehydration for 2-3 hours, cool down to 60-70°C, add 36kg toluene diisocyanate (TDI), 0.4kg triethylene glycol Base diamine, 12kg dibutyl phthalate (DBP), under the condition of nitrogen protection, react at 80-90°C for 4h and cool to about 60°C to prepare polyurethane prepolymer.

[0036] After heating 60kg of road petroleum asphalt (70#) to melting, mix it with 60kg of diesel oil and stir evenly to obtain diluted asphalt.

[0037] Next, according to the same method as in Example 1, high-performance polyurethane asphalt concrete 2# was prepared.

Embodiment 3

[0039] A kind of polyurethane bituminous concrete is prepared according to the following steps:

[0040]Add 88kg of polyether diol (molecular weight: 1000) into the reaction kettle, the temperature inside the kettle is 100-120°C, vacuumize and dehydrate for 2-3 hours, then lower the temperature to 60-70°C, add 20kg of 1,6-hexamethylene diisocyanate, 0.48kg Dibutyltin dilaurate (DBDTL), 12kg dioctyl phthalate (DOP), under the condition of nitrogen protection, react at 80-90°C for 4h and cool to about 60°C to prepare polyurethane prepolymer.

[0041] After heating 60kg of road petroleum asphalt (70#) to melting, mix it with 60kg of gasoline and stir evenly to obtain diluted asphalt.

[0042] Next, according to the same method as in Example 1, high-performance polyurethane asphalt concrete 3# was prepared.

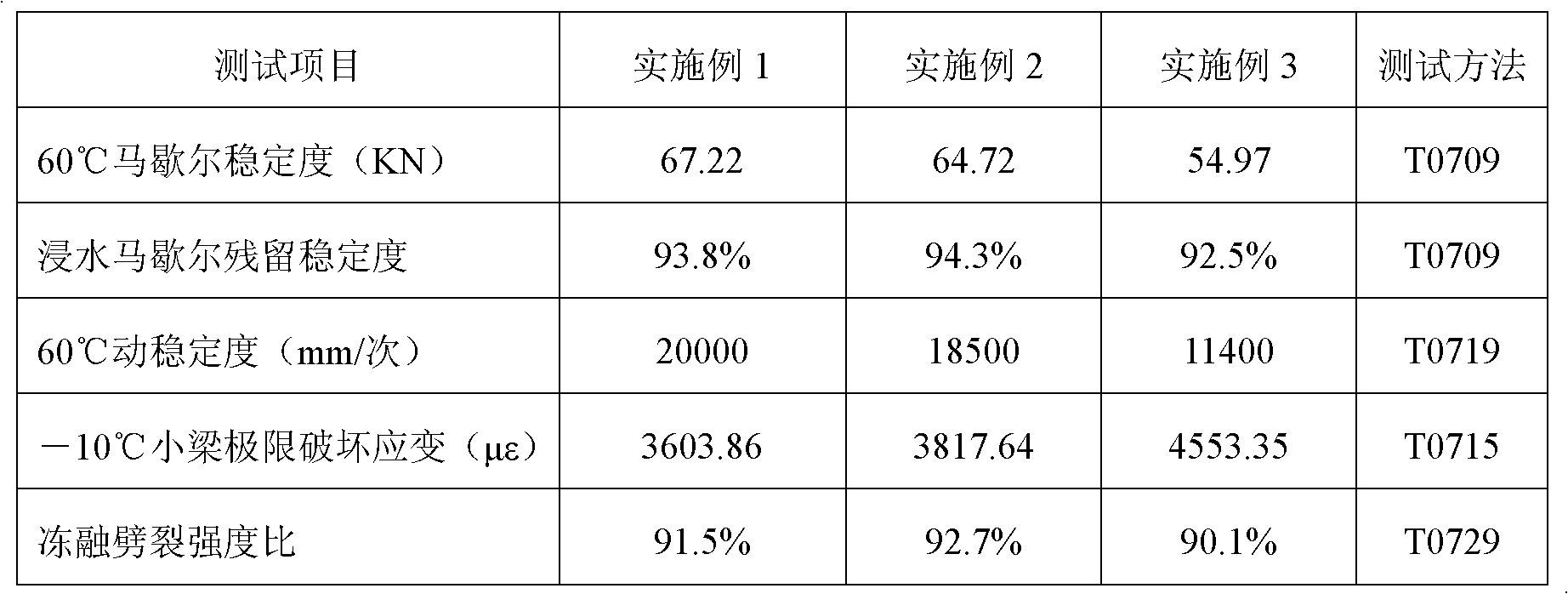

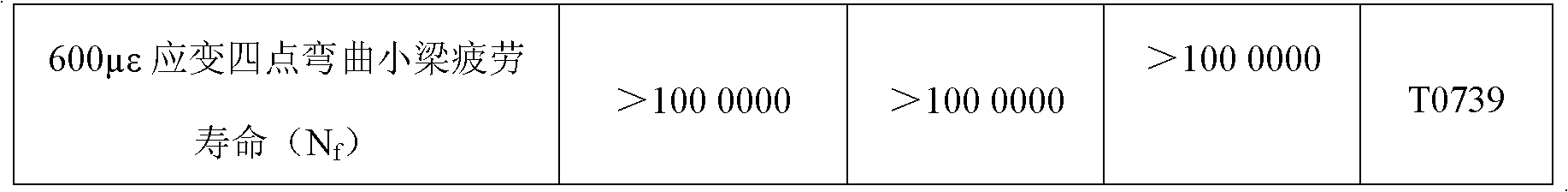

[0043] The polyurethane asphalt concrete described in the present invention is formed into a test piece, cured and tested according to the specification "Test Regulations fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com