Conducting asphalt concrete and its prepn process

A technology of asphalt concrete and conductive asphalt, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as increased resistivity, and achieve the effect of improving road performance and electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

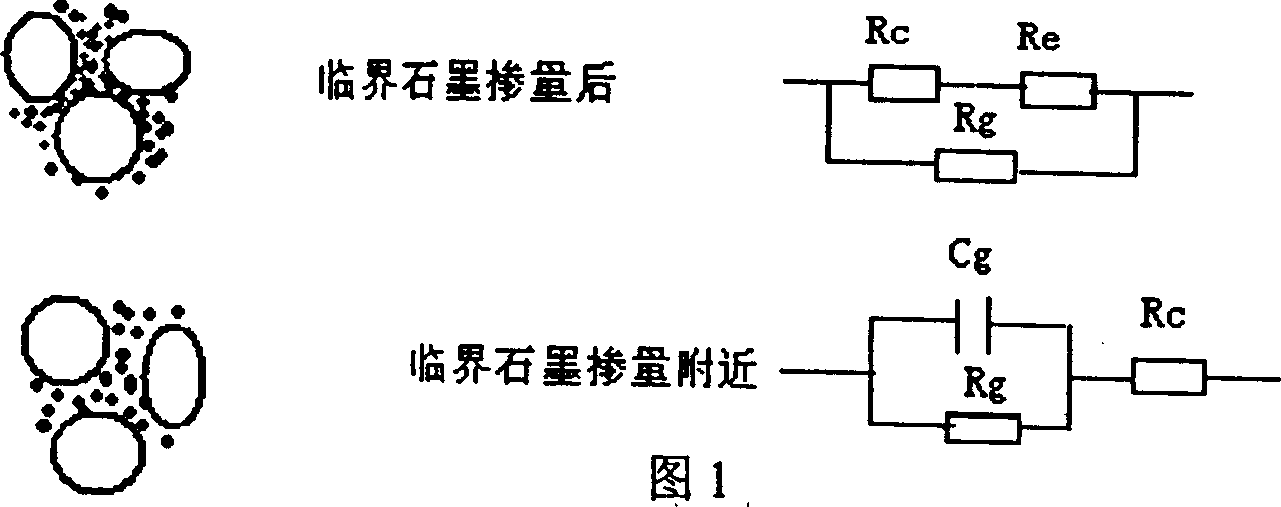

Method used

Image

Examples

Embodiment 1

[0038] AC-10I conductive asphalt concrete

[0039] Table 1 Synthetic gradation design pore size of AC-10I asphalt mixture (mm) 9.5 4.75 2.36 1.18 0.6 0.3 0.15 0.075 Synthetic gradation 100.0 98.8 68.9 48.8 37.9 23.0 14.6 7.6 (%)

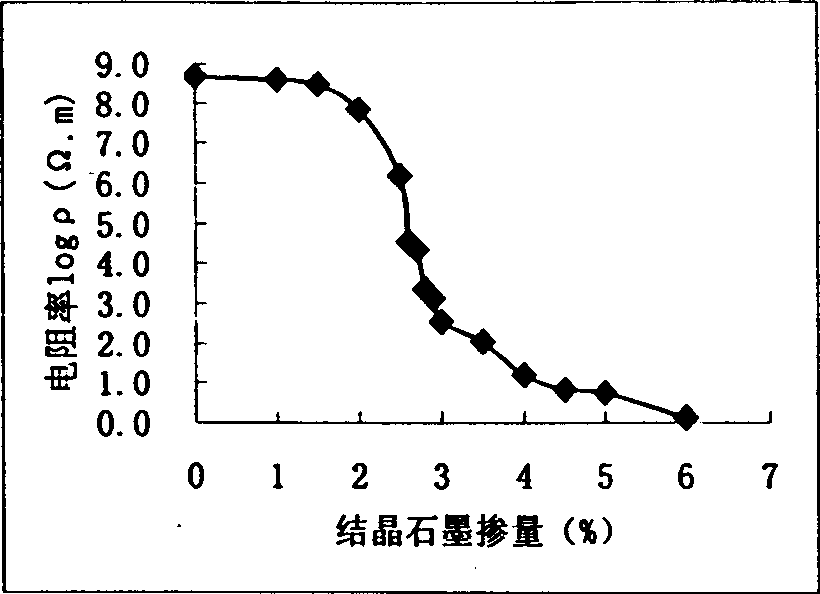

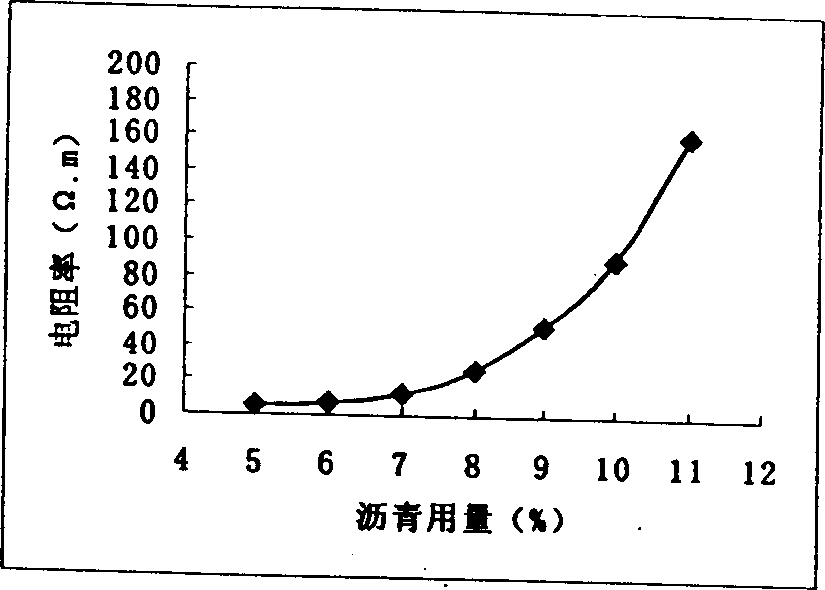

[0040] Microcrystalline graphite conductive asphalt concrete: asphalt content 7%, microcrystalline graphite content 12%, resistivity 75.4Ω m; crystalline graphite conductive asphalt concrete: bitumen content 6.5%, crystalline graphite content 4%, resistivity 25.3 Ω m .

Embodiment 2

[0042] Superpave12.5 conductive asphalt concrete

[0043] Table 2 Synthetic gradation design pore size (mm) of Superpave12.5 asphalt mixture 19 13.2 9.5 4.75 2.36 1.18 0.6 0.3 0.15 0.075 Synthetic gradation (%) 100 96.9 76.7 49.5 32.7 23.3 18.3 13.6 10.8 7.4

[0044] Microcrystalline graphite conductive asphalt concrete: the amount of asphalt is 6.5%, the amount of microcrystalline graphite is 10%, and the resistivity is 63.2Ω·m; the amount of crystalline graphite conductive asphalt concrete: the amount of asphalt is 6.2%, the amount of crystalline graphite is 5%, and the resistivity is 10.5Ω·m .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com