Test device for asphalt mixture resisting moving water scouring

A technology of asphalt mixture and test device, which is applied in the direction of measuring device, material inspection product, analysis material, etc., can solve the problem of not being able to evaluate the scouring effect of asphalt mixture well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

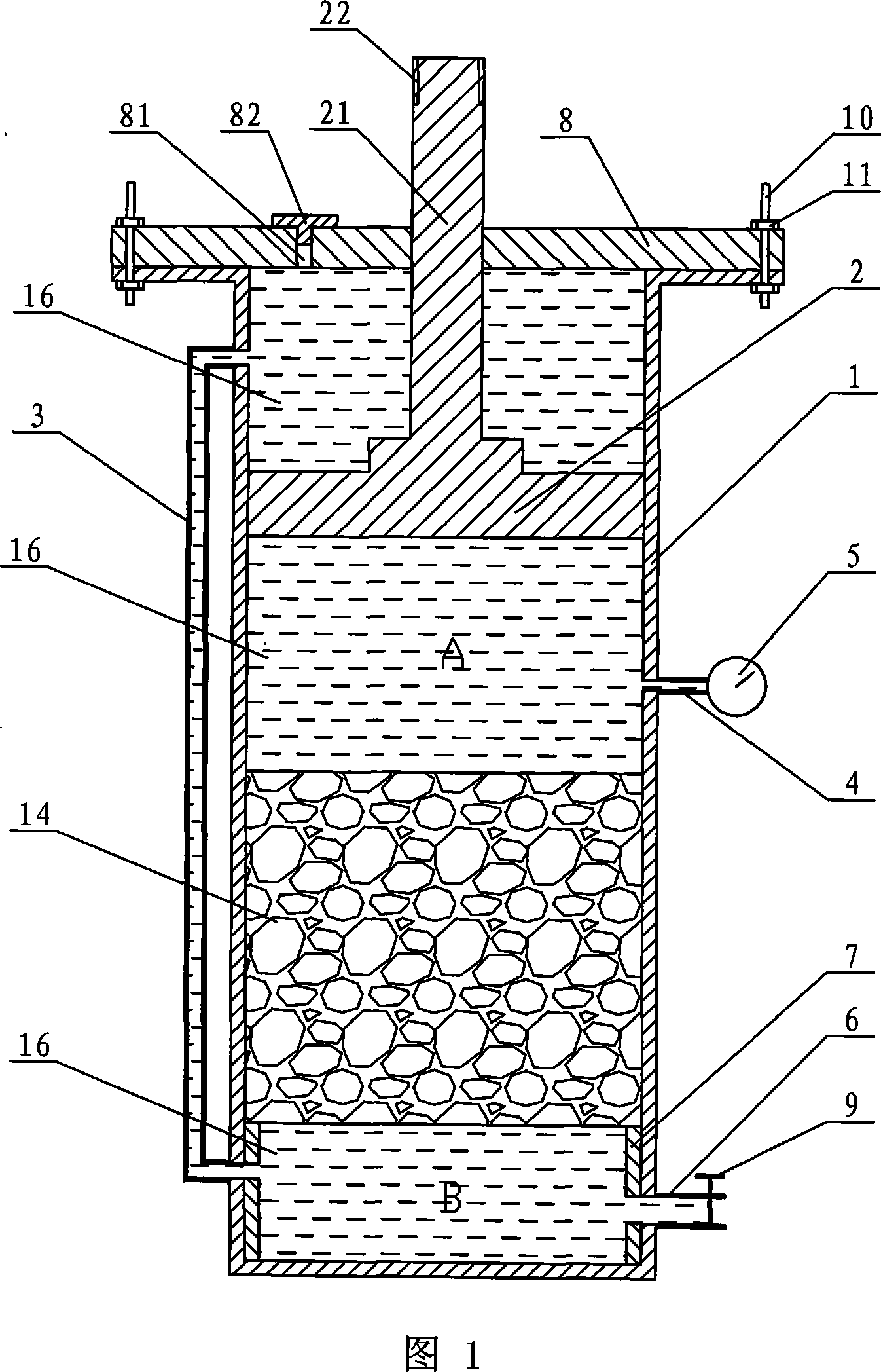

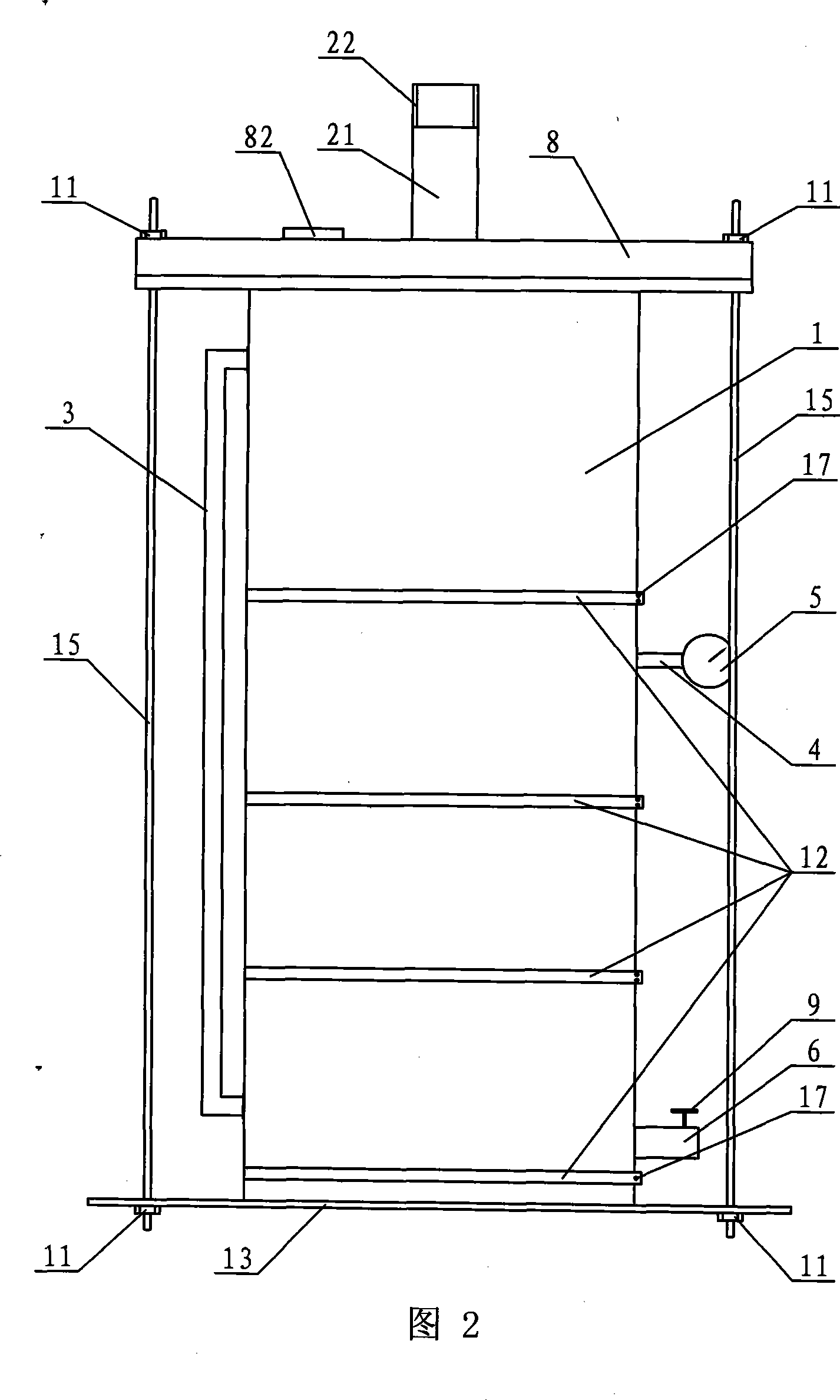

[0007] Specific Embodiment 1: This embodiment is described in conjunction with FIG. 1. This embodiment consists of a flushing barrel 1, a piston 2, a conduit 3, an upper water pipe 4, a pressure gauge 5, a lower water pipe 6, a support 7, an upper cover 8 and a valve. 9 components, the bottom of the inner cavity of the flushing barrel 1 is provided with a support 7, the upper part of the inner cavity of the flushing barrel 1 is provided with a piston 2, the top of the flushing barrel 1 is provided with an upper cover 8, and the upper end of the conduit 3 is arranged on the side of the flushing barrel 1. Above the wall, the lower end of the conduit 3 is arranged below the side wall of the flushing barrel 1, the upper water pipe 4 is arranged on the side wall of the flushing barrel 1, the upper water pipe 4 is provided with a pressure gauge 5, and the side wall of the flushing barrel 1 is provided below There is a lower water pipe 6 with a valve 9 on the lower water pipe 6. The l...

specific Embodiment approach 2

[0008] Specific Embodiment 2: This embodiment is described with reference to FIG. 1 . In this embodiment, the tail of the piston rod 21 on the piston 2 is provided with an external thread 22 . The external thread 22 is used to connect the piston rod 21 with the upper pressure head of the testing machine.

specific Embodiment approach 3

[0009] Specific embodiment three: this embodiment is described in conjunction with Fig. 1, the difference between this embodiment and specific embodiment one is: this embodiment also adds a rubber stopper 82, the upper cover 8 is provided with an air hole 81, and the rubber stopper 82 is arranged on In the air hole 81. Such design is to discharge the gas in the flush bucket 1 . Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com