Anti-seepage structure of composite lining deformation joints of ground fissure stratum tunnel and construction method thereof

A composite lining and deformation joint technology, applied in the direction of tunnel lining, tunnel, wellbore lining, etc., can solve the problem that the anti-seepage technology and anti-seepage structure are difficult to meet the anti-seepage requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

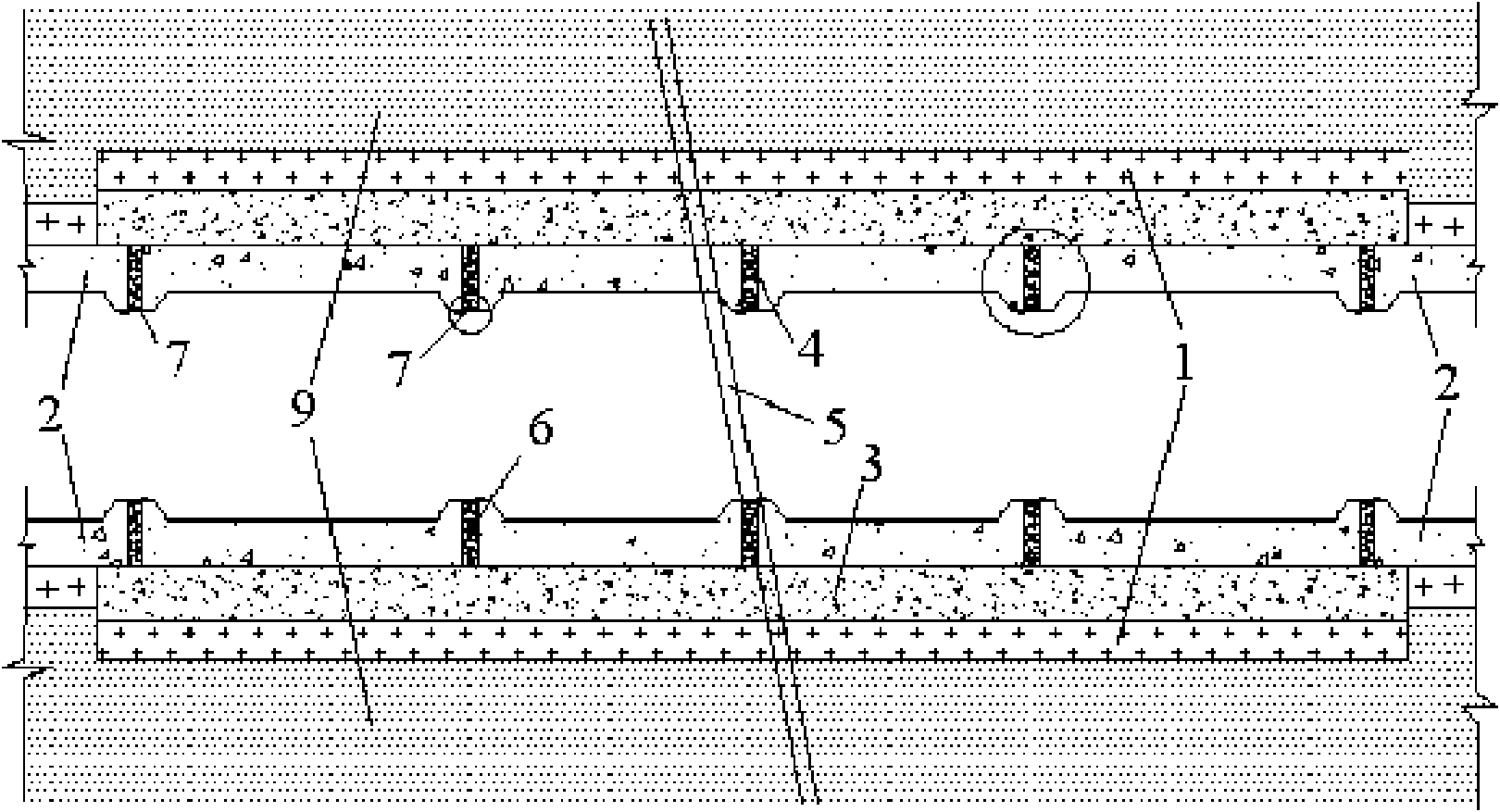

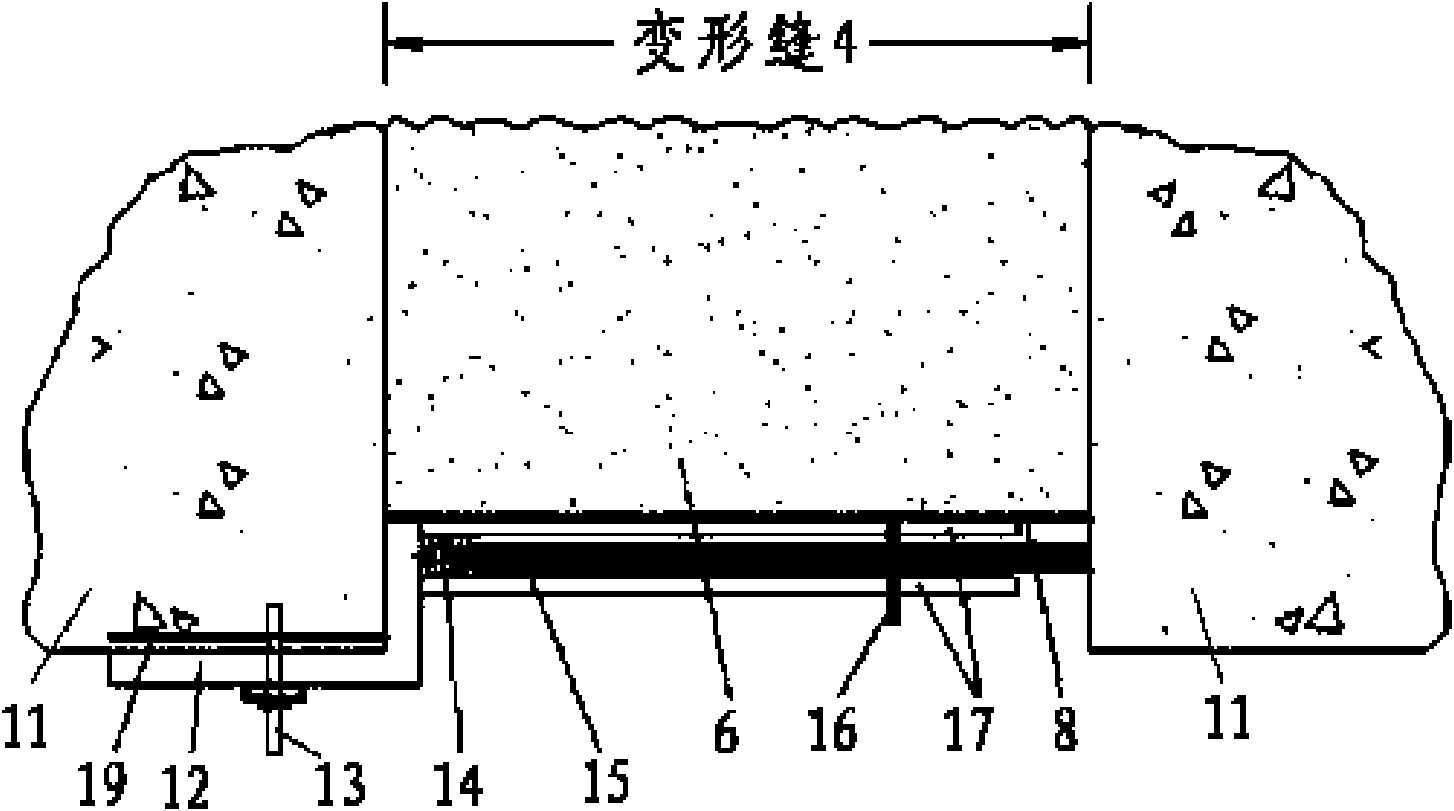

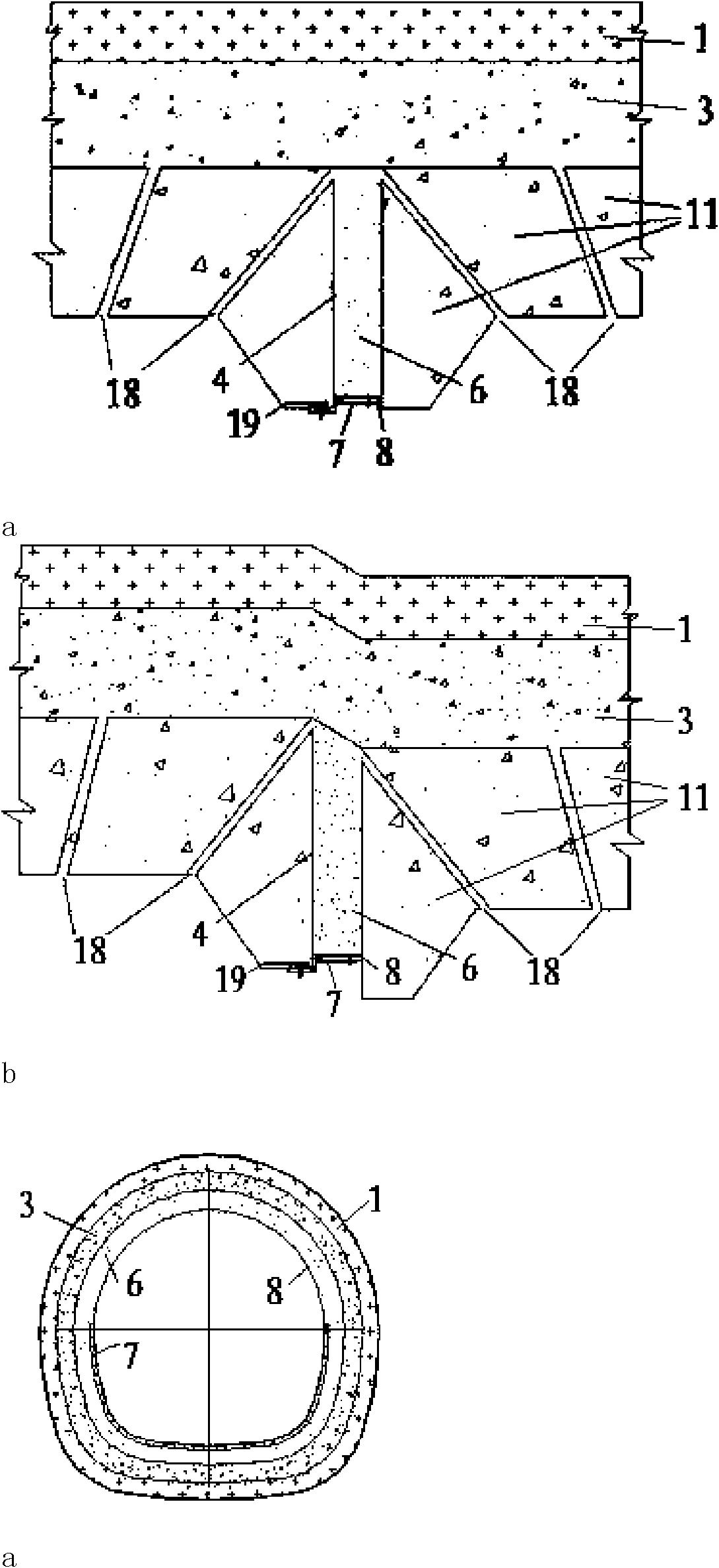

[0028] refer to figure 1 , figure 2 , image 3, the anti-seepage structure of the composite lining deformation joint of the ground fissure strata tunnel of the present invention is that in the ground fissure interval segment stratum tunnel, the primary support lining 1, the asphalt concrete lining 3 and the reinforced concrete lining are successively laid inwardly from the surrounding rock 9 of the tunnel Lining 2, in which primary support lining 1 and asphalt concrete lining 3 are poured along the ground fissure section, the thickness of asphalt concrete lining 3 is 30cm-50cm, and several deformation joints 4 are reserved in reinforced concrete lining 2, deformation joints The reserved width of 4 is 10cm-15cm. The reinforced concrete lining 2 extends 2m-2.5m along the direction of the tunnel at the outermost deformation joint 4, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com