Flexible connecting and sealing bitumastic impervious structure of tunnel deformation joint and constructing method

A technology of asphalt mastic and flexible connection, which is applied in tunnels, tunnel linings, underwater structures, etc., can solve the problems of anti-seepage technology and anti-seepage structure that are difficult to meet anti-seepage requirements, and achieve good hot-melt fluidity, Good rheology, significant anti-erosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] The construction method of the deformation joint anti-seepage structure adopted by the present invention is carried out in the following steps:

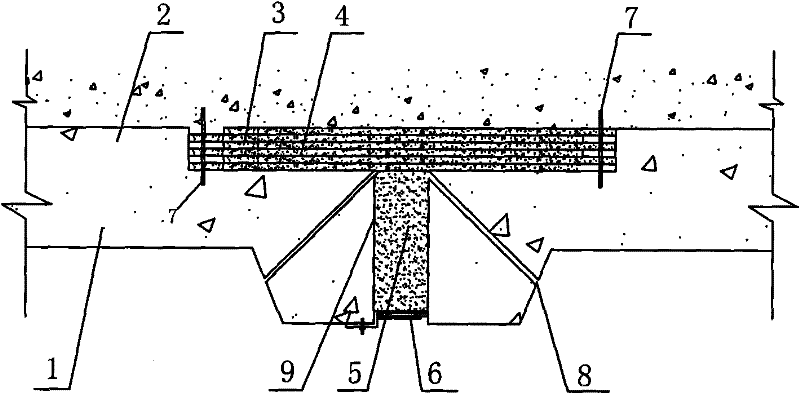

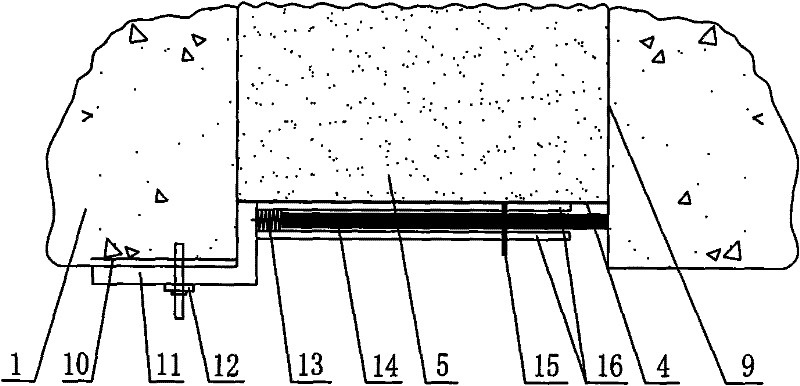

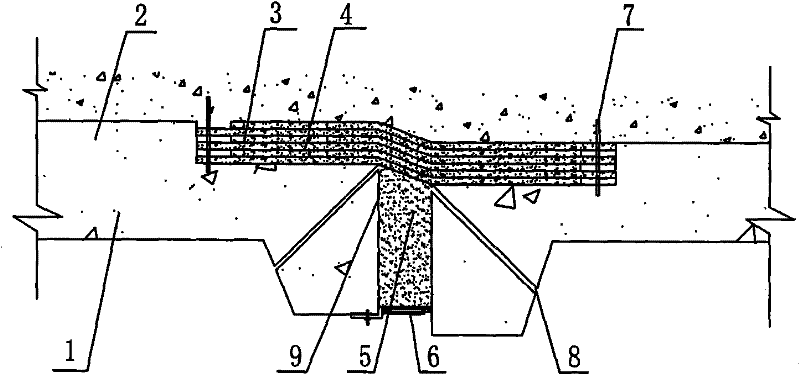

[0038] Step 1: Lay the composite layer 3 of the modified asphalt anti-seepage board.

[0039] Such as figure 1 As shown, when excavating a tunnel in the ground fissure interval section, the primary support lining 2 is first prepared, and then the modified asphalt anti-seepage board is anchored at the position corresponding to the deformation joint 9 of the reinforced concrete lining on the inner surface of the primary support lining 2 Layer 3 is on the inner wall of primary support lining 2. The reserved width of deformation joint 9 is 10cm-15cm. It consists of two adhesive layers, with a thickness of about 5-6cm and a length of about 40-50cm, wrapping the deformation joint 9 and extending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com