Method for preparing high-quality recycled fine aggregates by utilizing waste concrete

A technology for waste concrete and recycled fine aggregate, applied in the field of building materials, can solve the problems of high crushing index value, poor firmness, and weakened internal coarse aggregate performance, and achieves reduction of water demand ratio, improvement of durability, and improvement of firmness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The raw materials used are 6-year-old discarded concrete with a strength grade of C30 collected from a demolition site, and the raw stones are granite particles with a maximum particle size of 31.5mm.

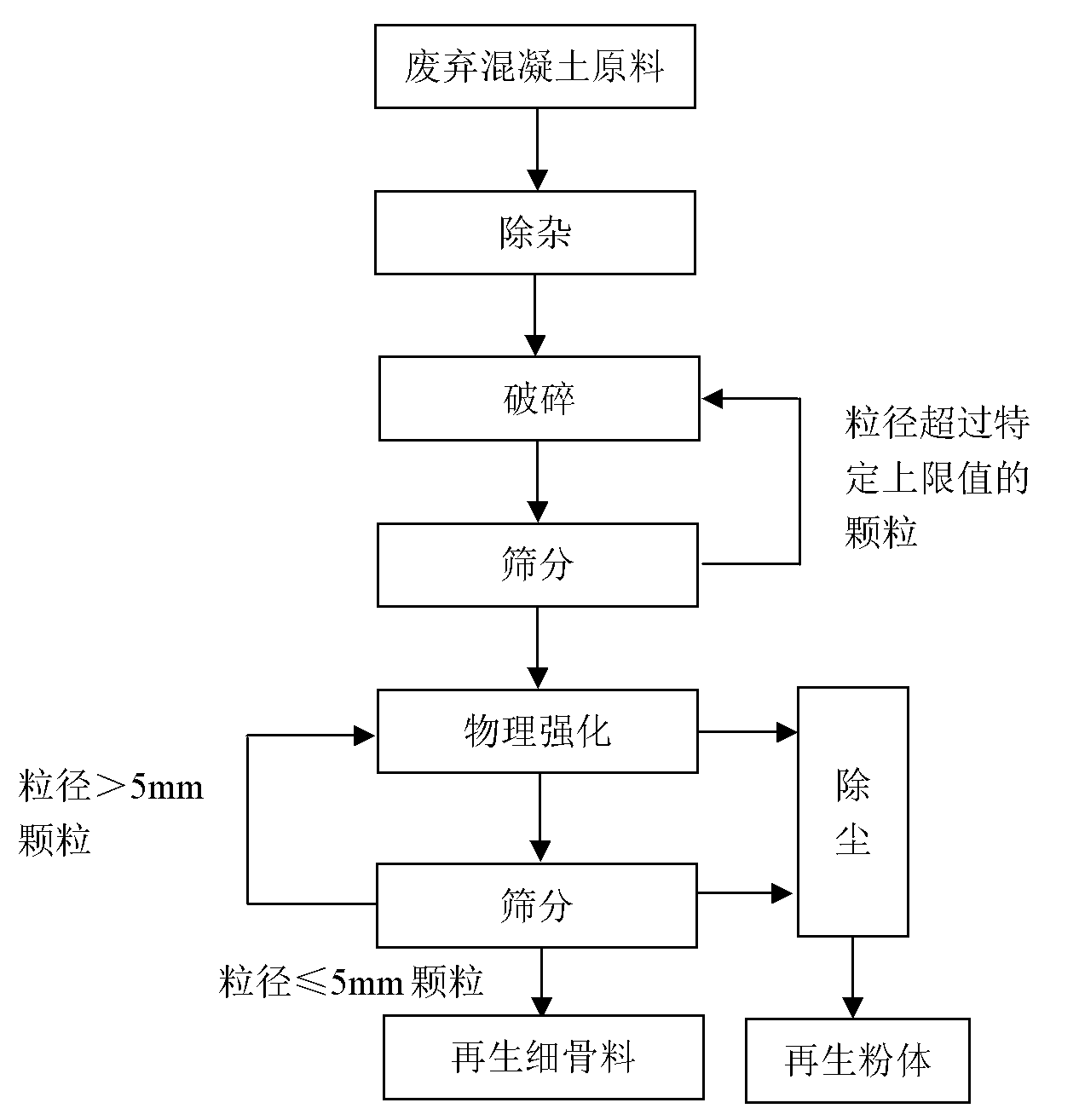

[0021] according to figure 1 The preparation process shown in the present invention is produced according to the method of using waste concrete to prepare high-quality recycled fine aggregate, including the following specific steps:

[0022] (1) Collect waste concrete, use a hammer crusher to process concrete blocks into particles with a particle size below 10mm as aggregate particles, and use manual selection and magnetic separation to remove wood, plastic, and metal in waste concrete before and after crushing Materials and other sundries, in this example, according to the crushing capacity of the crushing equipment used, the specific upper limit is set to 10mm, and the material particles whose particle size exceeds the specific upper limit after crushing are screened o...

Embodiment 2

[0032] The raw materials used are 12-year-old discarded concrete with a strength grade of C30 collected from a demolition site, and the raw stones are granite particles with a maximum particle size of 26.5mm.

[0033] according to figure 1 The preparation process shown in the present invention is produced according to the method of using waste concrete to prepare high-quality recycled fine aggregate, including the following specific steps:

[0034] (1) Collect waste concrete, use a hammer crusher to process concrete blocks into particles with a particle size below 8mm as aggregate particles, and use wind separation method combined with magnetic separation method to remove wood, plastic, steel materials and other impurities in waste concrete In this example, the specific upper limit is set to 8mm, and the material particles whose particle size exceeds the specific upper limit after crushing are screened out and then crushed again until the specific upper limit is met;

[0035]...

Embodiment 3

[0043] The raw materials used are 16-year-old discarded concrete with a strength grade of C20 collected from a demolition site, and the raw stones are granite particles with a maximum particle size of 31.5mm. according to figure 1 The preparation process shown in the present invention is produced according to the method of using waste concrete to prepare high-quality recycled fine aggregate, including the following specific steps:

[0044] (1) Collect waste concrete, manually remove wood, plastic and other sundries in waste concrete, use jaw crusher to process concrete blocks into particles with a particle size below 5mm as aggregate particles, and use magnetic separation to remove steel bars and other impurities , in this example, the specific upper limit is set to 5mm. The crushing process adopts a multi-stage crushing method. The materials processed by the crushing equipment are screened, and the obtained material particles with a particle size of no more than 5mm are used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com