Feed water adjusting agent and method for restoring normal water of feed

A conditioner and feed technology, applied in animal feed, animal feed, additional food elements, etc., can solve the problems of feed mildew and low water retention rate, and achieve the effects of high water retention rate, high accuracy, and improved automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

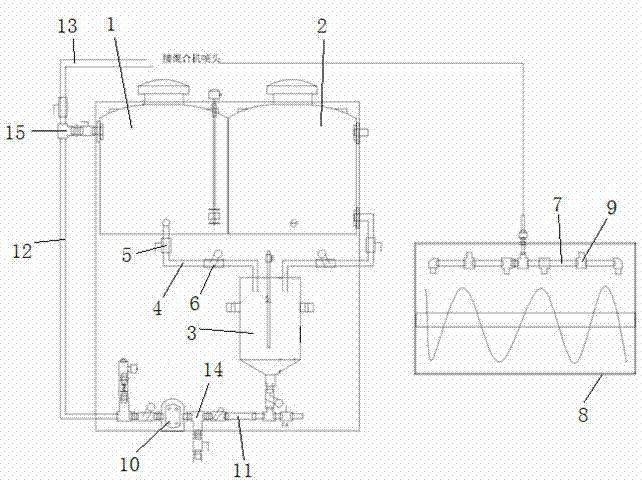

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Sucrose fatty acid ester (HLB value 12) 5%, sucrose fatty acid ester (HLB value 13) 5%, sucrose fatty acid ester (HLB value 14) 10%, propionic acid 30.0%, ammonium propionate 40.0% , water 10.0%.

Embodiment 2

[0035] Example 2: Sucrose fatty acid ester (HLB value 11) 3%, sucrose fatty acid ester (HLB value 13) 10%, sucrose fatty acid ester (HLB value 14) 7%, propionic acid 35.0%, ammonium propionate 35.0% , water 10.0%.

Embodiment 3

[0036] Example 3: Sucrose fatty acid ester (HLB value 11) 3%, sucrose fatty acid ester (HLB value 12) 6%, sucrose fatty acid ester (HLB value 14) 11%, propionic acid 40.0%, ammonium propionate 30.0% , water 10.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com