Fresh-keeping agent for bacillus subtilis and preparation method thereof

A Bacillus subtilis and preservative technology is applied in the field of Bacillus subtilis preservative and its preparation, and achieves the effects of achieving freshness, reducing the risk of mildew, and prolonging the storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

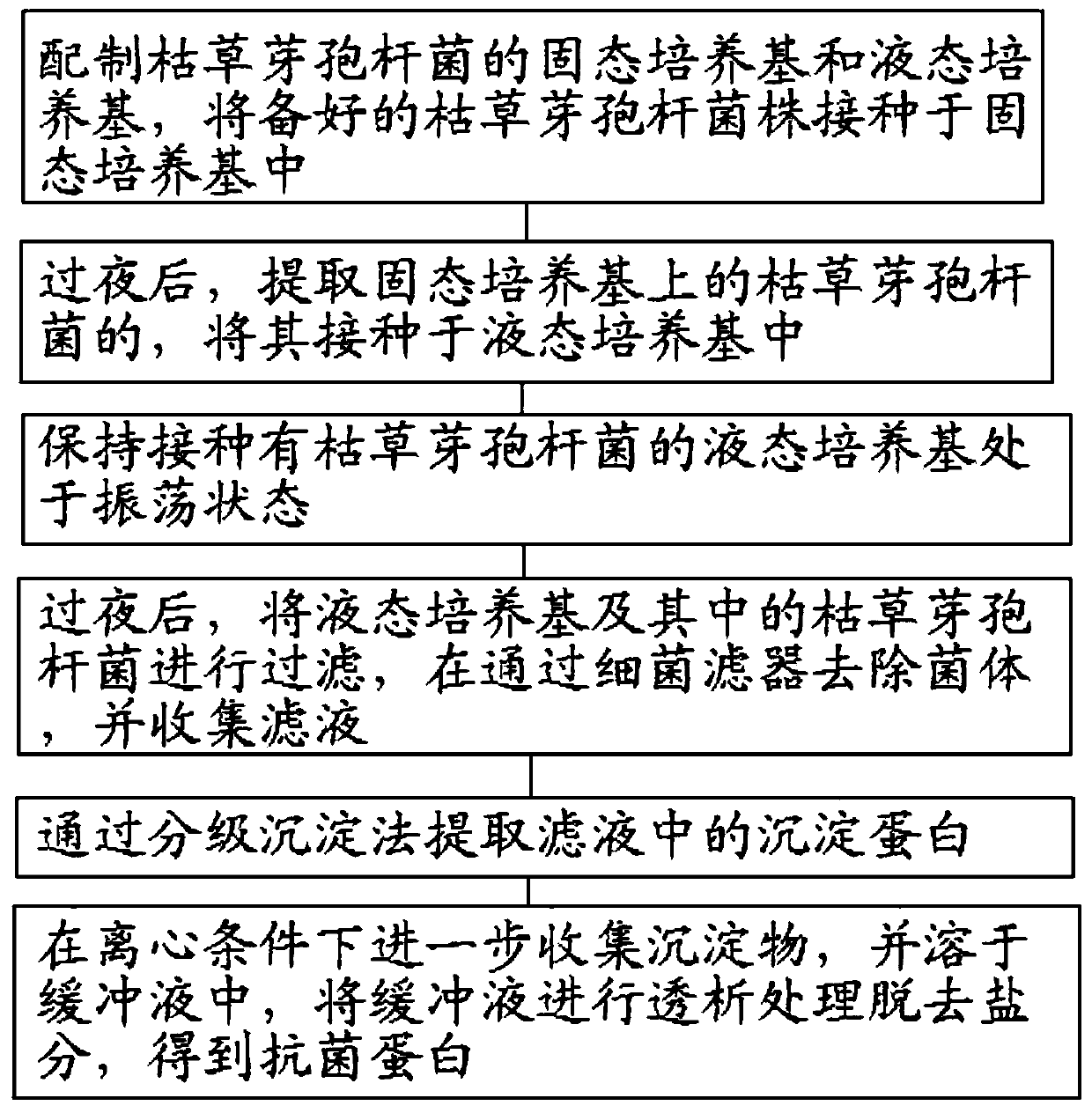

Image

Examples

Embodiment 1

[0031] Prepare solid medium for Bacillus subtilis: beef extract 1.0-5.0g, peptone 5g, NACl4g, agar 10g, water 450ml, liquid medium: peptone 10g, potassium hydrogen phosphate 5g, magnesium sulfate 10g, glycerol 8g, water 1000ml, The prepared Bacillus subtilis strains were inoculated in solid medium. After overnight, the Bacillus subtilis on the solid medium was extracted and inoculated into the liquid medium. At 25°C and 165 r / min, keep the liquid medium inoculated with Bacillus subtilis in a shaking state for 12 hours. The liquid culture medium and the Bacillus subtilis in it are filtered, the bacterial cells are removed through the bacterial filter, and the filtrate is collected. The precipitated protein in the filtrate was extracted by gradient concentrations of ammonium sulfate, and the concentration difference of each gradient of ammonium sulfate was 10%. Centrifuge at 7500r / min and 5°C for 15min to further collect the precipitate, dissolve it in sodium phosphate saline ...

Embodiment 2

[0033] Prepare solid medium for Bacillus subtilis: beef extract 1.0-5.0g, peptone 10g, NACl7g, agar 15g, water 800ml, liquid medium: peptone 15g, potassium hydrogen phosphate 8g, magnesium sulfate 20g, glycerol 5g, water 1200ml, The prepared Bacillus subtilis strains were inoculated in solid medium. After overnight, the Bacillus subtilis on the solid medium was extracted and inoculated into the liquid medium. At 30°C and 170 r / min, the liquid medium inoculated with Bacillus subtilis was kept in a shaking state for 16 hours. The liquid culture medium and the Bacillus subtilis in it are filtered, the bacterial cells are removed through the bacterial filter, and the filtrate is collected. The precipitated protein in the filtrate was extracted by gradient concentrations of ammonium sulfate, and the concentration difference of each gradient of ammonium sulfate was 10%. The precipitate was further collected by centrifugation at 8000r / min and 6°C for 20min, and dissolved in a sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com