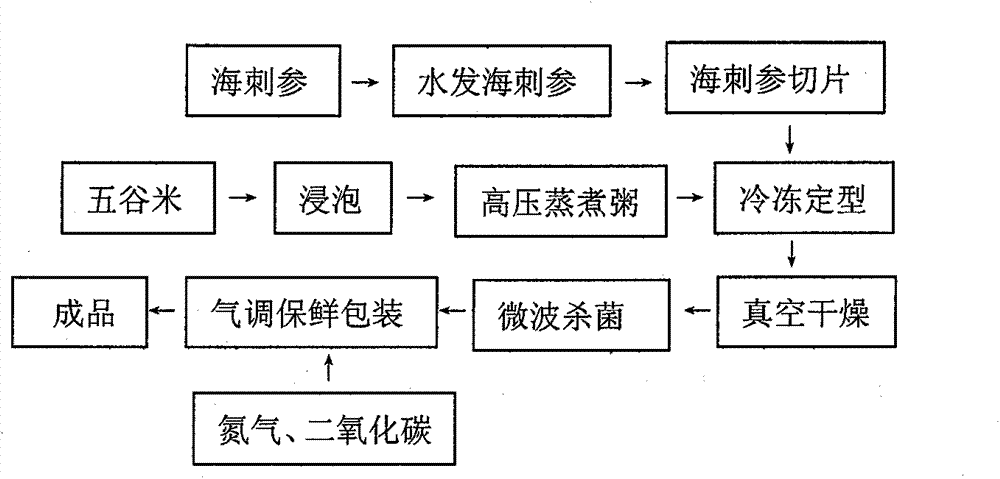

Vacuum freeze-drying instant sea cucumber five-cereal health care porridge preparation method

A technology for vacuum freeze-drying and health care porridge, applied in food preparation, food science, application and other directions, can solve problems such as eating and storage defects, and achieve the effect of ensuring food safety, hygienic and convenient consumption, and fast rehydration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Making Sea Cucumber Slices

[0028] Take 10kg of salted sea cucumber (100 heads / kg), put it into a 50L stainless steel bucket, add 30kg of drinking water, desalinate for 6 hours, and change the water twice, put the desalted 10kg of sea cucumber in a 500L stainless steel pressure cooker Add 100L of edible water, heat to 121°C, pressure 1.2MPa, keep warm for 30min, cool to 30°C, take it out, put it into a 50L stainless steel bucket, and add 30L of pure water. In the refrigerated room of 0-5 ℃, the water was fed for 24 hours, and 50 kg of sea cucumbers were obtained, and 50 kg of sea cucumbers were vertically placed in the XL-75 multifunctional slicer trough (Guangzhou Xulang Machinery Co., Ltd. Equipment Co., Ltd.) controlled the slicing speed to 40 slices / min, and the thickness of sea cucumber slices was 1.5mm, and obtained 8,000 slices of sea cucumber (20kg), about 400 slices per kilogram, which can be added to 1,000 bowls of porridge.

[0029] Step 2: High-pre...

Embodiment 2

[0045] 1. Sea cucumber slices. Take 10kg of sea japonicus as raw material after watering 20kg, place 20kg of sea cucumber vertically in the slot of XL-75 multifunctional slicer (Guangzhou Xulang Machinery Equipment Co., Ltd.) and control the slice speed to 50 slices / min , sea cucumber slice thickness is 2.0mm, obtains sea cucumber slice 6000 (20kg).

[0046] 2. High pressure cooking porridge. Take 94kg of purple (big) rice and soak it in drinking water at 25°C for 60 minutes, remove it, place it in a stainless steel 500L high-pressure cooking pot (Hangzhou Huihe Machinery Equipment Co., Ltd.), add 94kg of purple (big) rice 282kg of edible water with a weight ratio of 3 times, seal the lid, control the temperature at 110°C, pressure 0.10MPa, stirring speed 36r / min, time 50min, cool to 60°C; then pack it into stainless steel bowls with a diameter of 140mm, thickness 30mm, weight 376g, 1000 bowls of vacuum freeze-dried purple (large) rice porridge 376kg raw material.

[0047] ...

Embodiment 3

[0057] Step 1: Making Sea Cucumber Slices

[0058] Take 10kg of salted sea cucumber (100 heads / kg), put it into a 50L stainless steel bucket, add 30kg of drinking water, desalinate for 6 hours, and change the water twice, put the desalted 10kg of sea cucumber in a 500L stainless steel pressure cooker Add 100L of edible water, heat to 121°C, pressure 1.2MPa, keep warm for 30min, cool to 30°C, take it out, put it into a 50L stainless steel bucket, and add 30L of pure water. In the refrigerated room of 0-5 ℃, the water was fed for 24 hours, and 50 kg of sea cucumbers were obtained, and 50 kg of sea cucumbers were vertically placed in the XL-75 multifunctional slicer trough (Guangzhou Xulang Machinery Co., Ltd. Equipment Co., Ltd.) controlled the slicing speed to 40 slices / min, and the thickness of sea cucumber slices was 1.5mm, so as to obtain 8000 slices (20kg) of sea cucumber, about 400 slices per kilogram, which can be added to 1000 bowls of porridge.

[0059] Step 2: High-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com