Nano-regulation-based multi-scale insulating and heat-conducting PC composite material and preparation method thereof

A composite material, insulation and heat conduction technology, applied in the field of multi-scale insulation and heat conduction PC composite materials and its preparation, can solve the problems of long time consumption, complex reaction, poor controllability, etc., to improve the specific surface area and roughness, and overcome the thermal resistance effect , the effect of inhibiting reunion behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

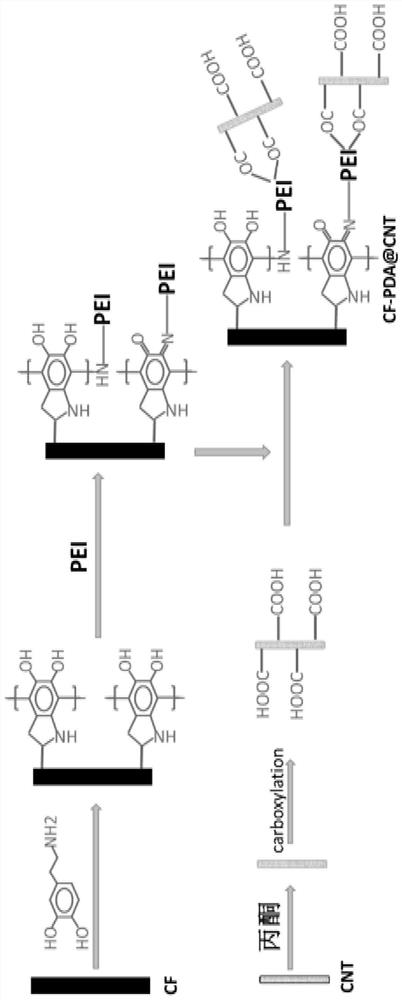

[0030] In the present invention, the preparation method of multi-scale thermally conductive filler (see the schematic diagram of the preparation method figure 1 ), including the following steps:

[0031] The aminated CF was put into PEI aqueous solution, and the intermediate was obtained by step-by-step ultrasonic treatment. The first ultrasonic stage was treated at 170-210W for 8-15min, and the second ultrasonic stage was treated at 45-80W for 5-8h; the intermediate and the carboxylated The chemically treated CNTs were ultrasonically treated at 15-45W for 5-10 hours, and then dried to obtain multi-scale thermally conductive fillers.

[0032] In the present invention, the amination process of CF is as follows: add Tris buffer solution to CF, then add ethanol for blending, add dopamine hydrochloride and stir to obtain a reaction dispersion; the reaction dispersion can be filtered, washed and dried ; The mass ratio of CF to dopamine hydrochloride is 1:0.05~0.3.

[0033]Dopamin...

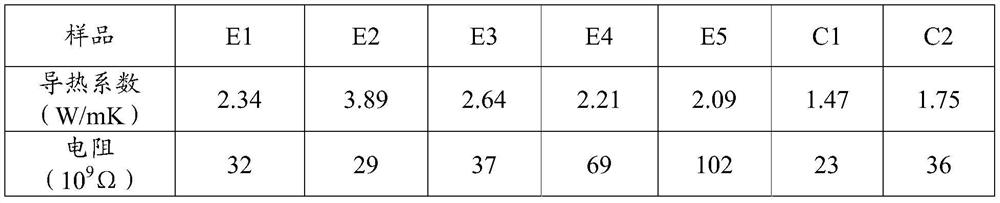

Embodiment 1

[0047] A method for preparing a multi-scale insulating and heat-conducting PC composite material based on nanometer regulation, comprising the following steps:

[0048] Preparation of S1 multiscale thermally conductive filler

[0049] (1) Packing drying treatment

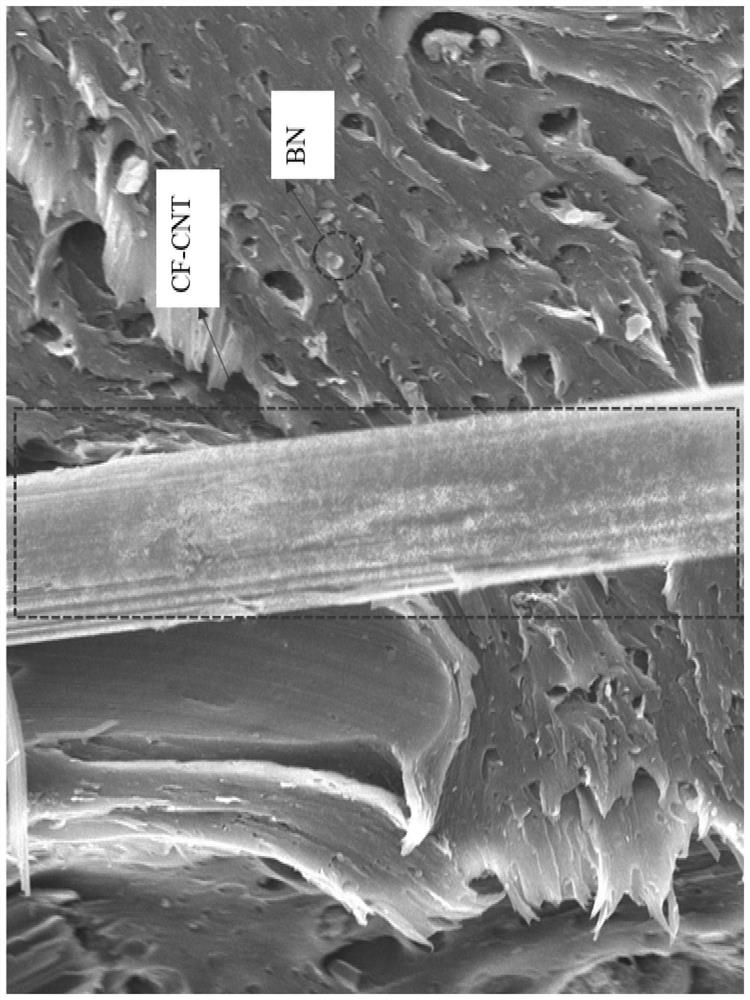

[0050] The multi-walled carbon nanotubes CNT, carbon fibers CF, and hexagonal boron nitride (h-BN) were all placed in a vacuum drying oven at 90°C for 8 hours.

[0051] (2) Preparation of Tris buffer solution

[0052] Weigh 1.2g of tris (Tris) into a 1L beaker, add deionized water to dissolve to obtain a 10mM Tris solution, then add concentrated hydrochloric acid dropwise to adjust the pH to about 8.5.

[0053] (3) Carboxylation treatment of CNT

[0054] CNTs were soaked in acetone for 24 hours to remove the surface sizing agent, cleaned with deionized water and dried in a vacuum oven at 80°C / 4h, and then mixed acid (concentrated sulfuric acid and concentrated nitric acid at a volume ratio of 3:1) at 60°C ) solu...

Embodiment 2

[0064] The difference between this embodiment and embodiment 1 is that in (5), the mass ratio of CF-PDA, PEI, and CNT-COOH is 2:2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com