Condensate water dripping preventing structure at water dripping pipe position of evaporator

A technology for preventing condensed water and evaporators, which is applied in the field of automotive air conditioning, and can solve problems such as passenger inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

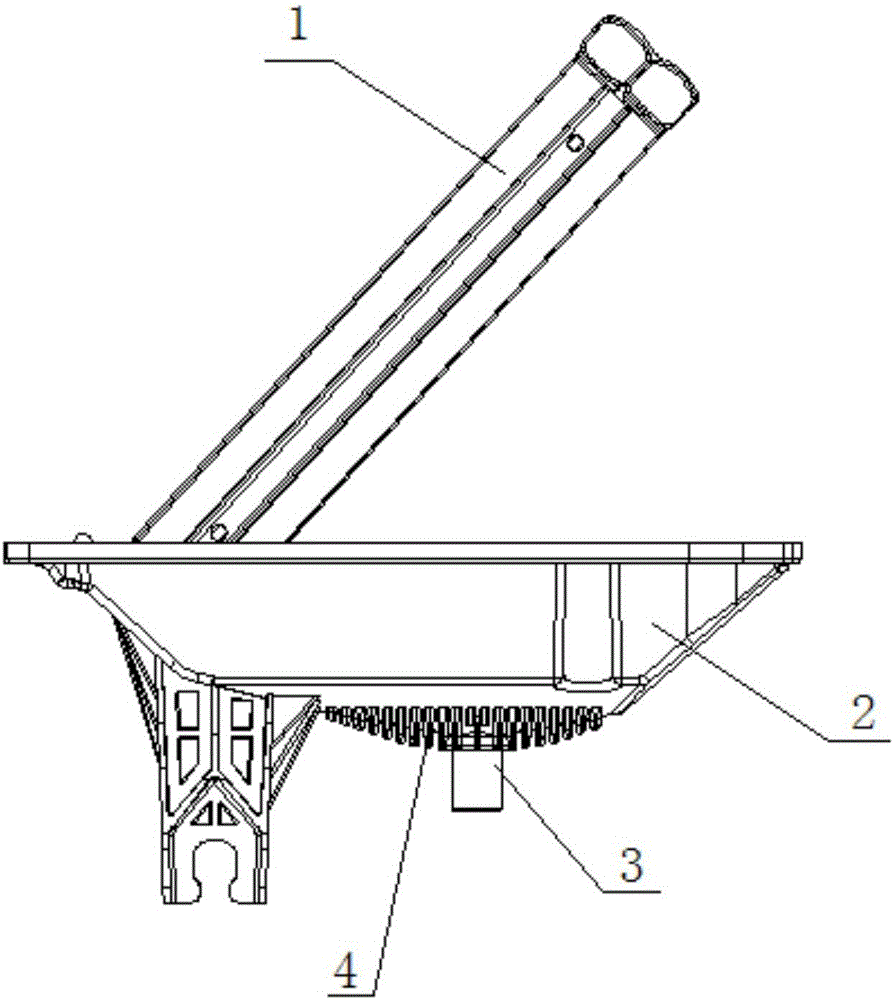

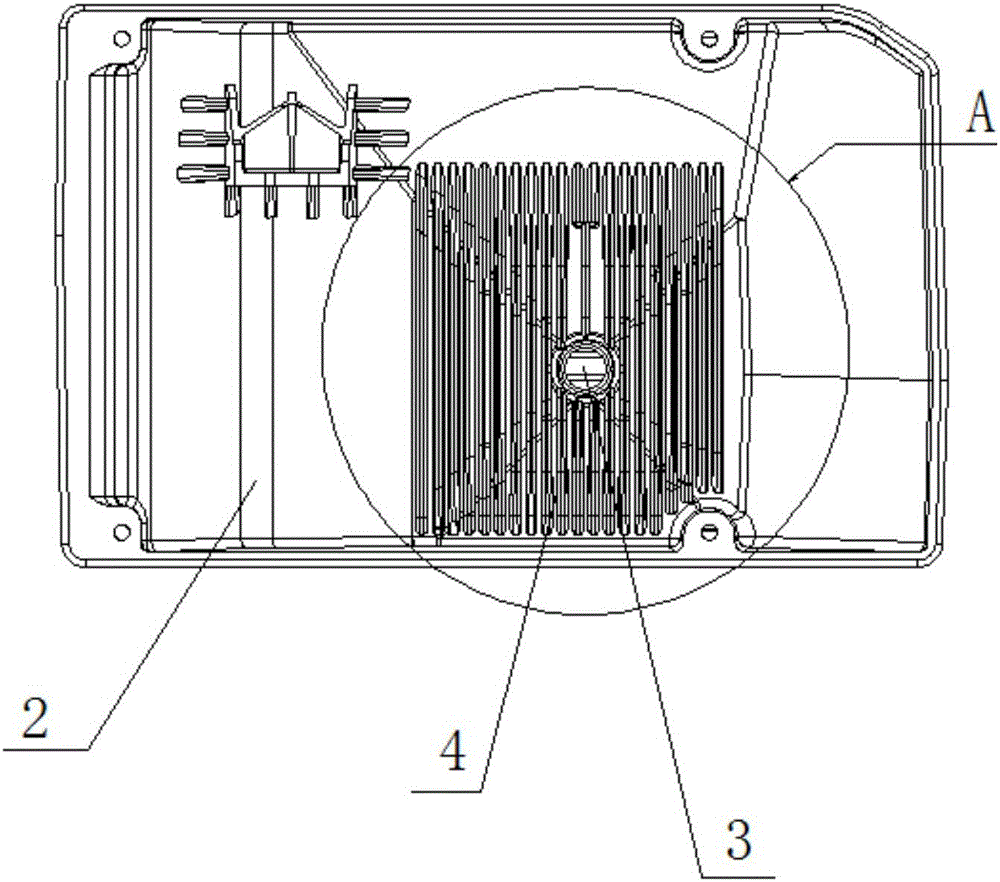

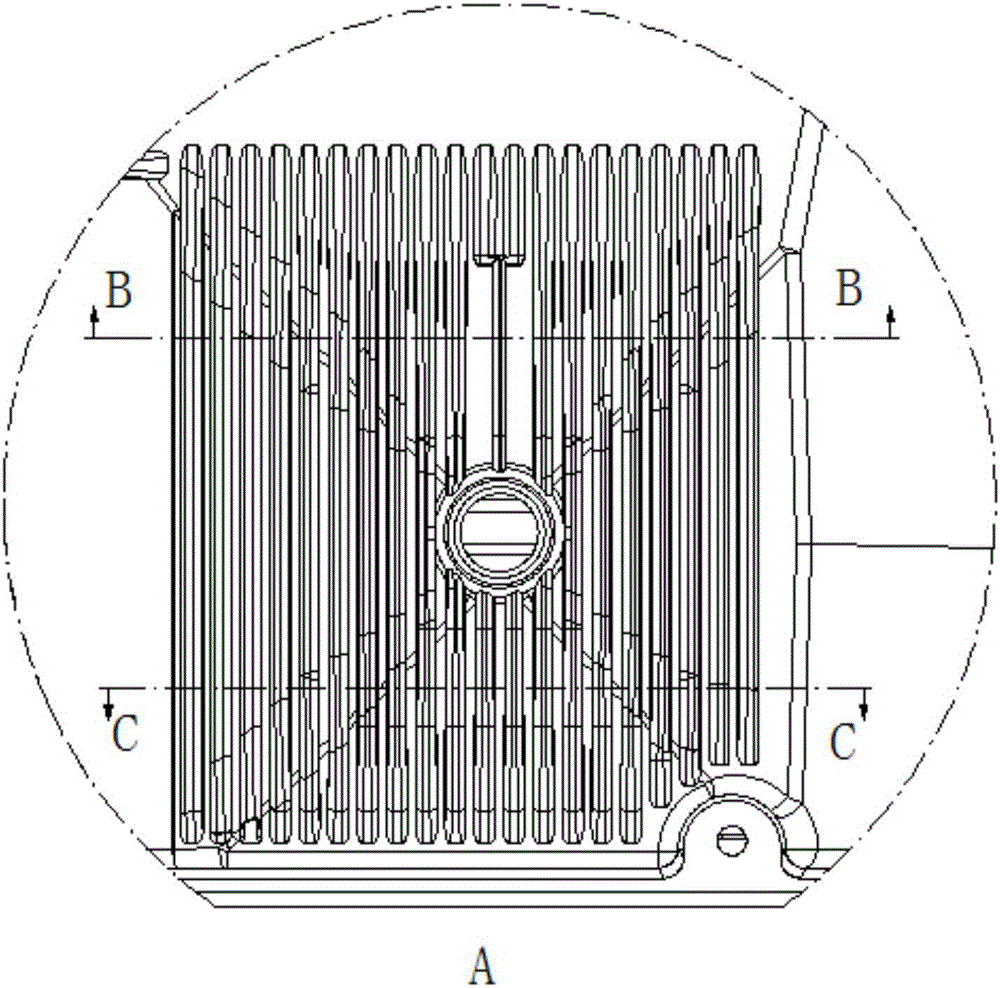

[0019] Such as Figure 1 to Figure 5 As shown, the present invention provides an anti-condensation water dripping structure at the drip pipe of the evaporator, including: an evaporator core 1, an evaporator lower shell 2 arranged outside the evaporator core 1, and an evaporator lower shell 2 The drip pipe 3 connected at the bottom and several ribs 4 arranged on the bottom surface of the lower shell 2 of the evaporator.

[0020] Specifically, several ribs 4 are parallel to each other. By adding the above-mentioned structure at the drip pipe 3, when condensed water precipitates on the surface of the lower shell 2 of the evaporator, the arrangement of the tight ribs 4 limits the flow of condensed water in the evaporator. With the free flow of the lower shell 2, the condensed water can evaporate freely, and will not accumulate and drip into the cab. At the same time, this design can save a waterproof sponge on the inner surface, and save a sponge to be pasted into the lower shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com