Down-drilling-preventive textile and production method thereof

A production method and technology for textiles, which are applied in textiles and papermaking, the production of furniture covers, household appliances, etc., can solve problems such as troublesome stitching processes, and achieve the effect of reducing the phenomenon of drilling down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

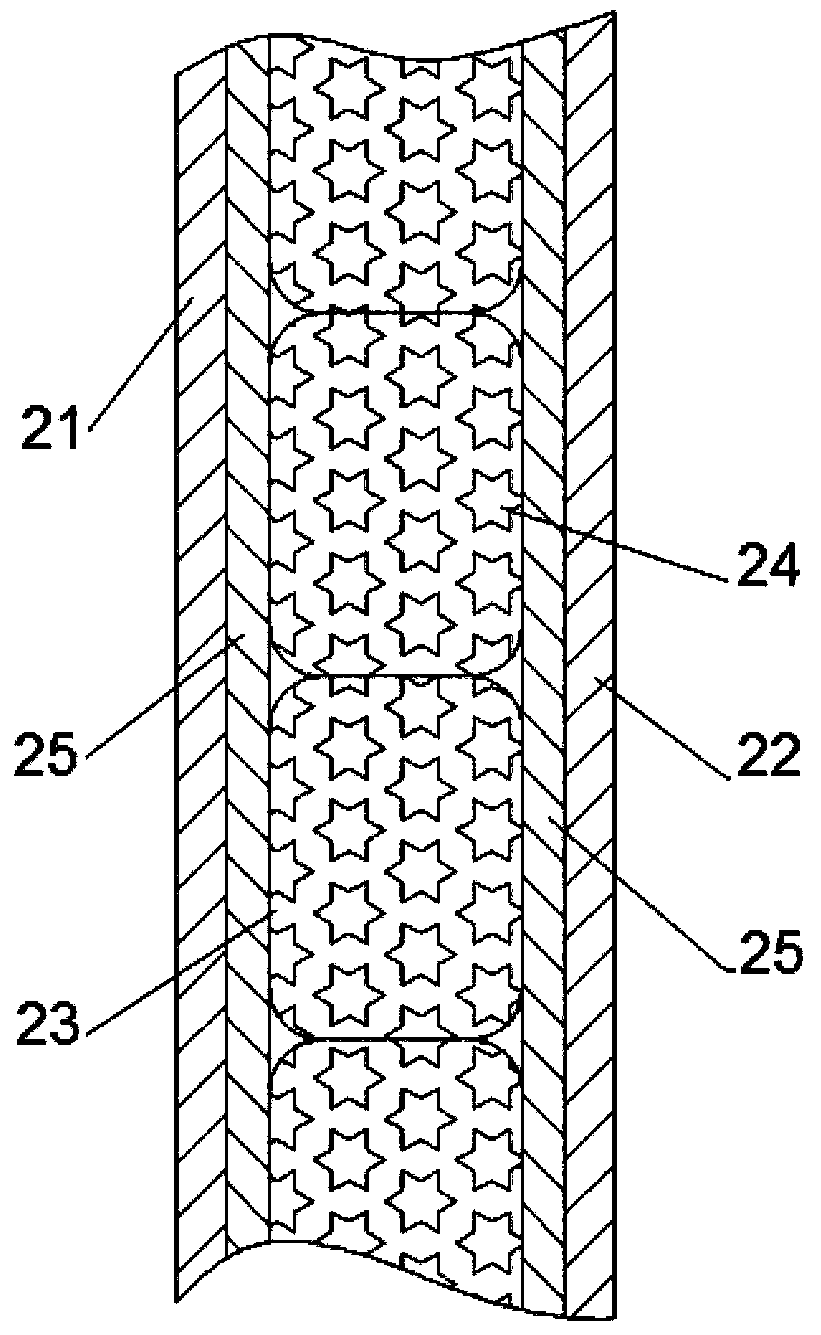

[0048] In a further embodiment of the present invention, there are multiple cavities, and the cavities are parallel to each other.

[0049] In a further embodiment of the present invention, the above-mentioned filaments are continuous filaments composed of one or more synthetic polymers.

[0050] In a further embodiment of the present invention, the filament is nylon, polyester, rayon, polyethylene, polypropylene, aramid, meta-aramid or any mixture thereof.

[0051] In a further embodiment of the invention, the filament is polyester.

[0052] In a further embodiment of the present invention, the filaments are made of continuous polyester filaments through single yarn twisting, plying, plying and twisting continuous filaments.

[0053] In a further embodiment of the present invention, the above-mentioned bottom thread 5 contains short-fiber sewing thread or textured thread.

[0054] In a further embodiment of the present invention, the short fibers contained in the bottom thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com