Lithium battery diaphragm preparation method based on mixed solvent multi-stage volatilization mechanism

A lithium battery separator and mixed solvent technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as poor mechanical strength and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

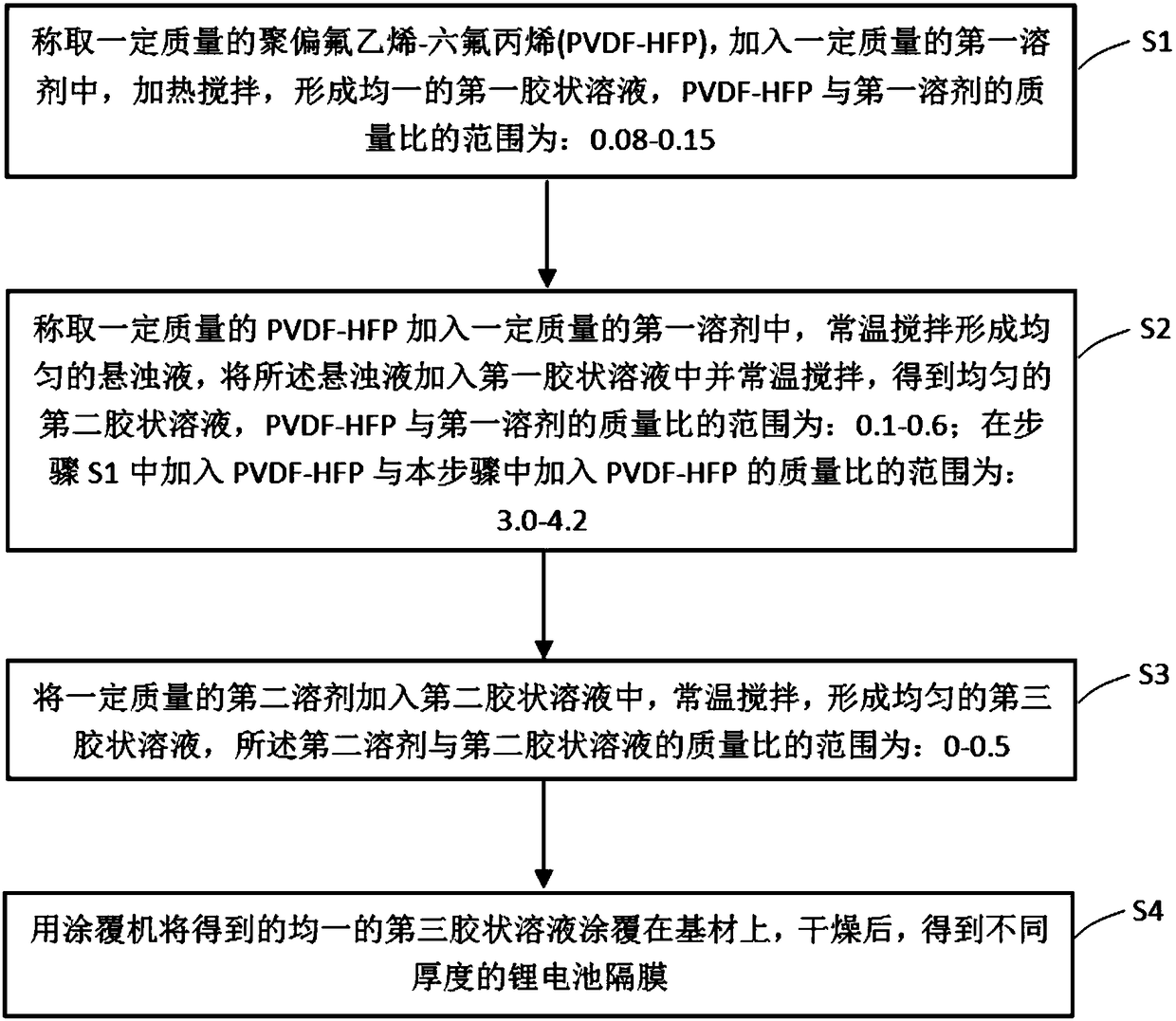

[0026] see figure 1 , the invention provides a method for preparing a lithium battery separator based on a mixed solvent multistage volatilization mechanism, comprising the following steps:

[0027] S1: Weigh a certain quality of PVDF-HFP, add a certain quality of acetone, the mass ratio of PVDF-HFP to acetone is: 0.1, and heat and stir in a water bath at 45°C-55°C to form a uniform first colloidal solution. Viscosity: 1500cp.

[0028] S2: Weigh a certain quality of PVDF-HFP and add it to a certain quality of acetone. The mass ratio of PVDF-HFP to acetone is 0.6. Stir at room temperature to form a uniform suspension, then add it to the first colloidal solution and stir at room temperature to obtain Uniform second colloidal solution, viscosity: 2000cp. The mass ratio of PVDF-HFP added in step S1 to PVDF-HFP added in this step is 3.0.

[0029] S3: Add a certain amount of NMP into the second colloidal solution, the mass ratio of NMP to the second colloidal solution is 0.2, and...

Embodiment 2

[0032] see figure 1 , the invention provides a method for preparing a lithium battery separator based on a mixed solvent multistage volatilization mechanism, comprising the following steps:

[0033] S1: Weigh a certain quality of PVDF-HFP, add a certain quality of acetone, the mass ratio of PVDF-HFP to acetone is: 0.12, and heat and stir in a water bath at 45-55°C to form a uniform first colloidal solution. The viscosity is: 2000cp.

[0034] S2: Weigh a certain mass of PVDF-HFP and add it to a certain mass of acetone, the mass ratio is: 0.4, stir at room temperature to form a uniform suspension, then add it to the first colloidal solution and stir at room temperature to obtain a uniform second colloidal solution Solution, viscosity: 3000cp. The mass ratio of PVDF-HFP added in step S1 to PVDF-HFP added in this step is 3.5.

[0035] S3: Add a certain amount of NMP into the second colloidal solution, the mass ratio of NMP to the solution is 0.4, and continue stirring to obtain...

Embodiment 3

[0038] see figure 1 , the invention provides a method for preparing a lithium battery separator based on a mixed solvent multistage volatilization mechanism, comprising the following steps:

[0039] S1: Weigh a certain amount of PVDF-HFP, add it into a certain amount of acetone, the mass ratio of PVDF-HFP to acetone is 0.14, and heat and stir in a water bath at 45-55°C to form a uniform first colloidal solution, the viscosity For: 2200cp;

[0040] S2: Weigh a certain quality of PVDF-HFP and add it to a certain quality of acetone. The mass ratio of PVDF-HFP to acetone is 0.3. Stir at room temperature to form a uniform suspension, and then add it to the first colloidal solution and stir at room temperature to obtain Uniform second colloidal solution, viscosity: 3000cp. The mass ratio of PVDF-HFP added in step S1 to PVDF-HFP added in this step is 3.8.

[0041] S3: Add a certain amount of DMF into the second colloidal solution, the mass ratio of DMF to the second colloidal solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com