Double-wall cooling blade, turbine blade applying cooling blade and gas turbine

A technology for cooling blades and double walls, which is applied in the direction of supporting components of blades, mechanical equipment, engine components, etc., can solve the problems of complex manufacturing process, difficult core removal process of core manufacturing and engineering application, etc. Achieve the effects of improving life, improving cooling efficiency, and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

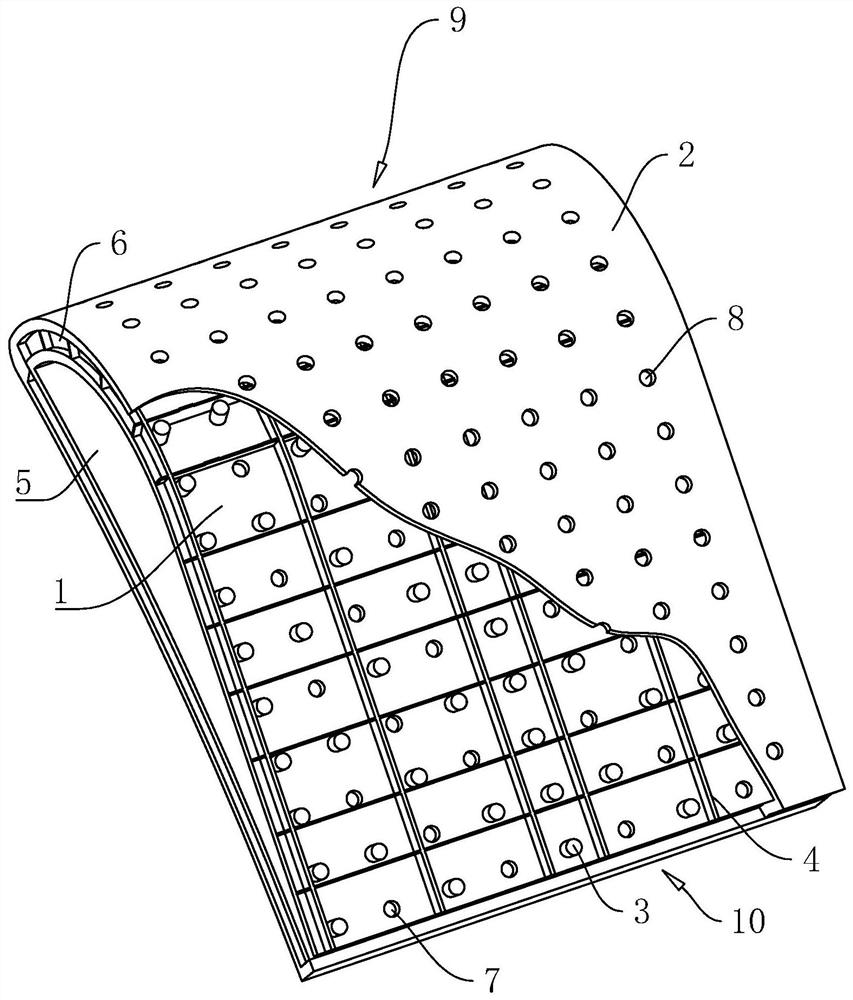

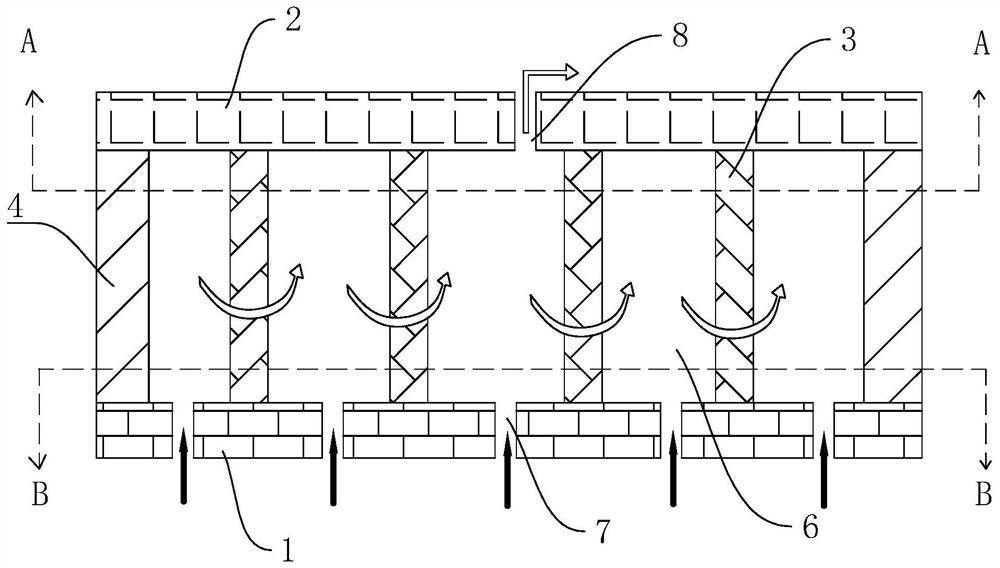

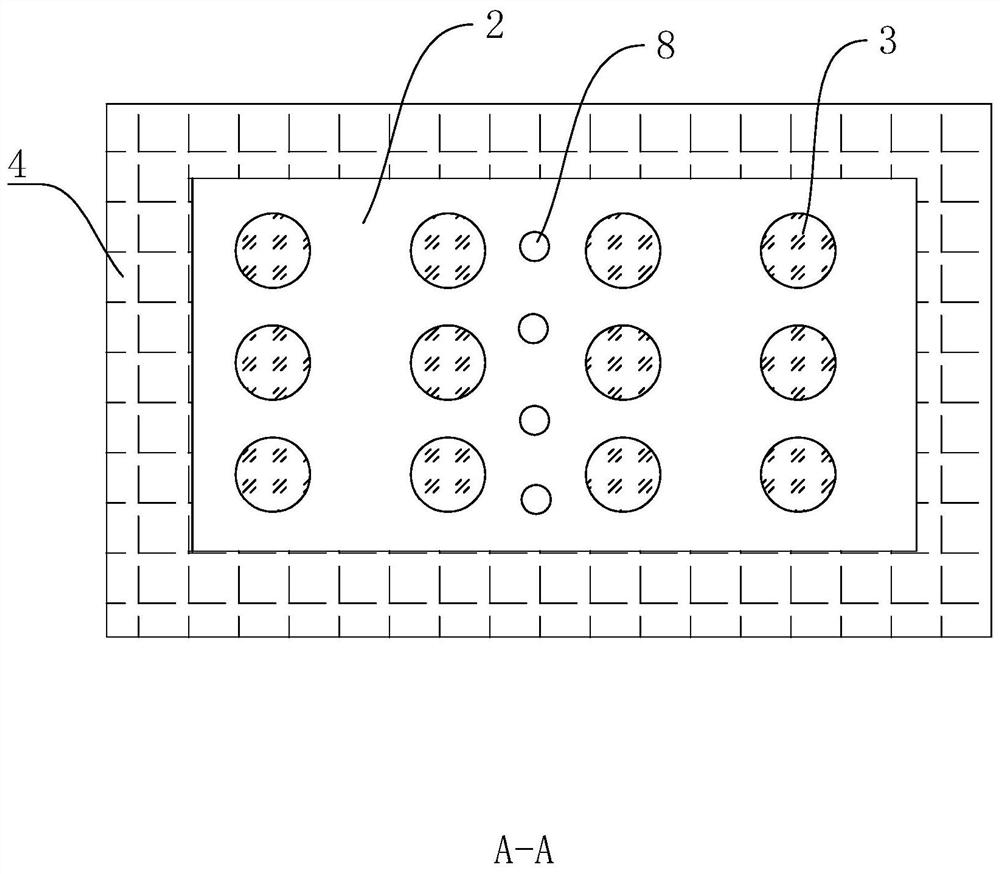

[0043] The embodiment of the present application discloses a double-walled cooling blade. refer to figure 1 , the double-walled cooling blade includes a blade inner wall 1 , a blade outer wall 2 , a heat exchange structure and a partition 4 . Wherein, the blade outer wall 2 is arranged around the periphery of the blade inner wall 1 , and the heat exchange structure and the partition plate 4 are both arranged between the blade inner wall 1 and the blade outer wall 2 . In this application, the outer wall 2 of the blade and the inner wall 1 of the blade are assembled and fixed after being separately processed, which can be processed and manufactured with low cost and high reliability under the existing technical conditions, and has important engineering practical value.

[0044] The inner wall 1 of the blade and the outer wall 2 of the blade can be in any shape, such as a rectangle, an irregular ring or a bow in cross-section, and the specific shape can be designed and selected ...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that one side of the partition 4 is fixedly connected to the inner wall 1 of the blade by means of welding, or is cast integrally with the inner wall 1 of the blade, and the other side of the partition 4 is at least partly closely connected to the outer wall 2 of the blade. Abut.

[0057] And on the basis of this embodiment, in order to improve the assembly convenience of the blade inner wall 1 and the blade outer wall 2, the column rib 3 and the blade inner wall 1 are fixed by welding or integral casting.

Embodiment 3

[0059] The difference between this embodiment and Embodiment 1 is that one side of the partition 4 is fixedly connected to the outer wall 2 of the blade by welding, or is cast integrally with the outer wall 2 of the blade, and the other side of the partition 4 is at least partly closely connected to the inner wall 1 of the blade. Abut.

[0060] And on the basis of this embodiment, in order to improve the assembly convenience of the blade inner wall 1 and the blade outer wall 2, the column rib 3 and the blade outer wall 2 are fixed by welding or integral casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com