Graphene production process

A production process, graphene technology, applied in the field of graphene preparation, can solve the problems of lower graphene performance, low graphene quality, increase of graphene defects, etc., to achieve the effect of improving efficiency, simplifying product quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

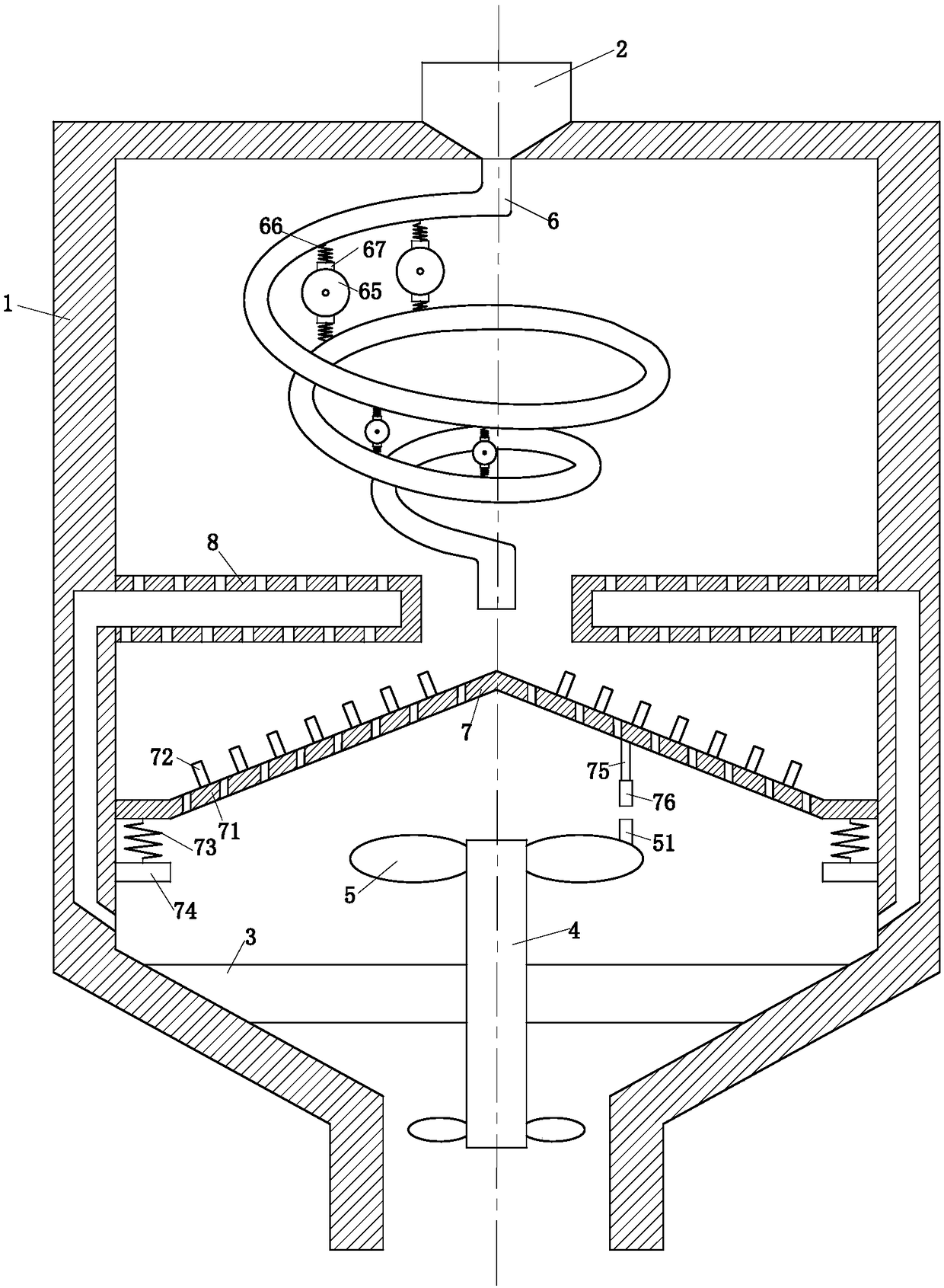

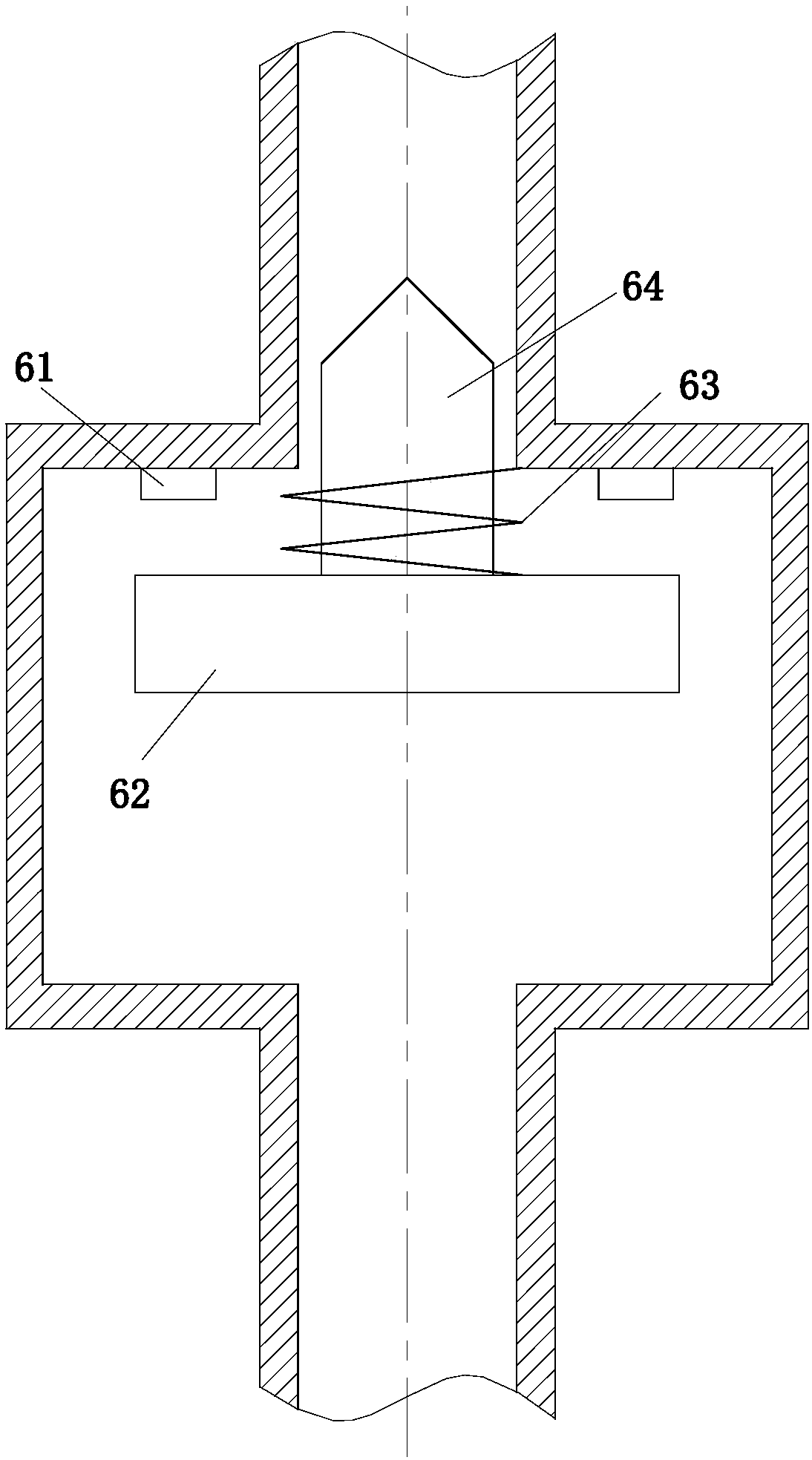

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

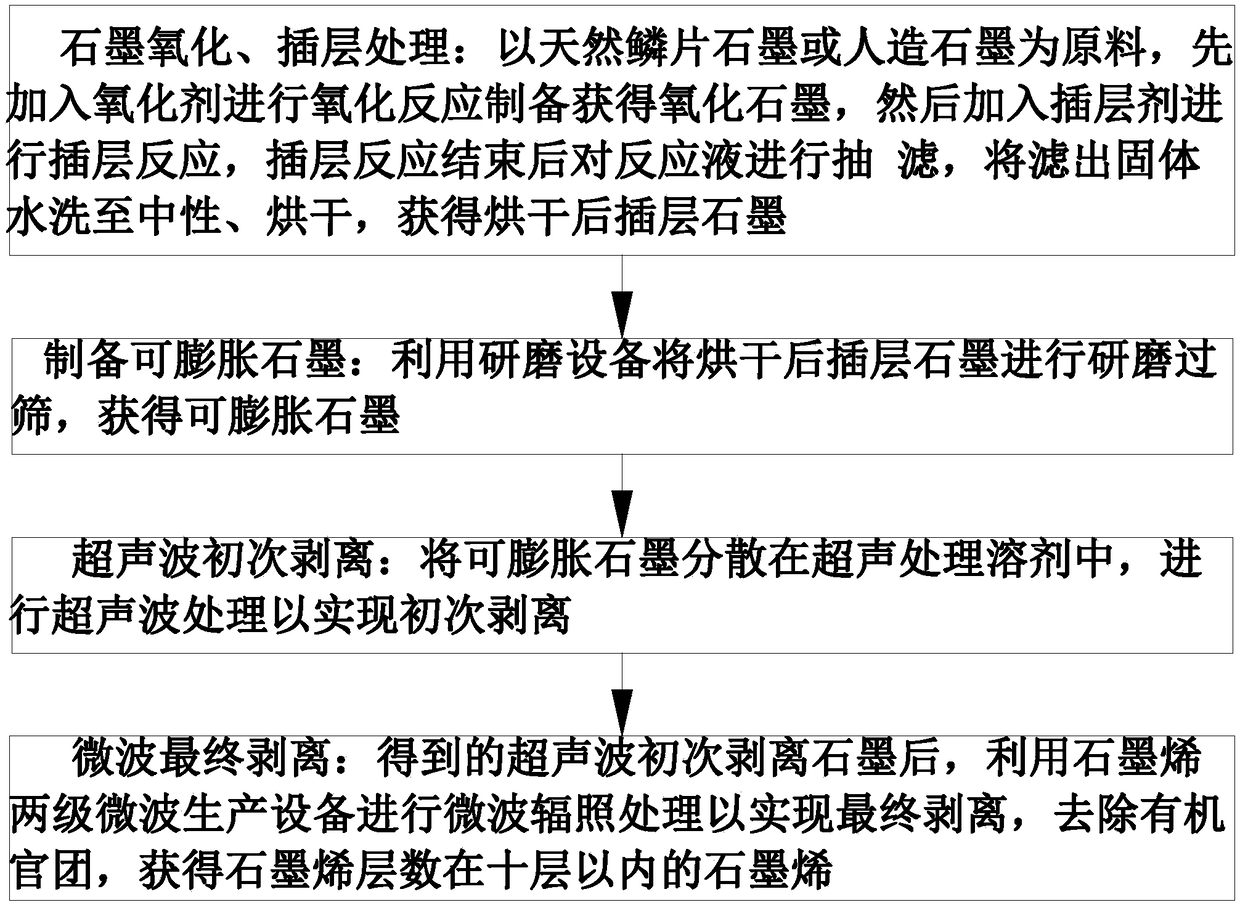

[0027] Such as Figure 1 to Figure 4 Shown, a kind of graphene production technique of the present invention, comprises the steps:

[0028] Step 1: Graphite oxidation and intercalation treatment: using natural flake graphite or artificial graphite as raw materials, first add an oxidizing agent for oxidation reaction to prepare graphite oxide, then add an intercalation agent for intercalation reaction. Suction filtration, washing the filtered solid with water to neutrality, and drying to obtain intercalated graphite after drying;

[0029] Step 2: preparing expandable graphite: using grinding equipment to grind and sieve the dried intercalated graphite prepared in step 1 to obtain expandable graphite;

[0030] Step 3: Ultrasonic primary peeling: d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com