Fog-dissipation and anti-dropping polyvinyl chloride greenhouse film and preparation method thereof

A polyvinyl chloride, anti-fog and non-drip technology, which is applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems of drop-free effect drop, poor durability, etc., to reduce the number of replacements and reduce labor intensity , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

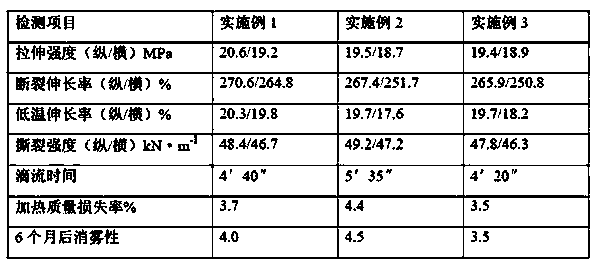

Examples

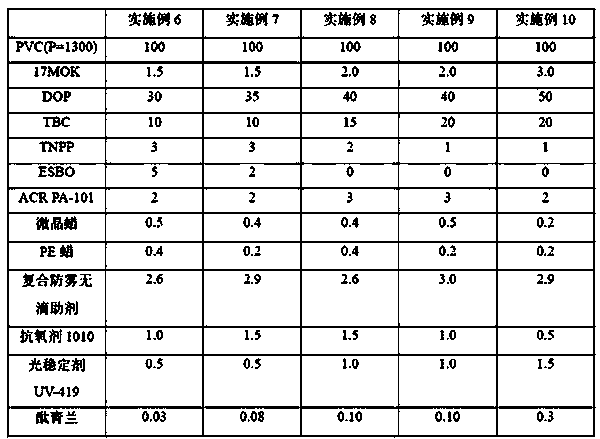

Embodiment 6~10

[0049] The composite anti-fogging and drip-free additive components (parts by weight) in Examples 6-10 are:

[0050]

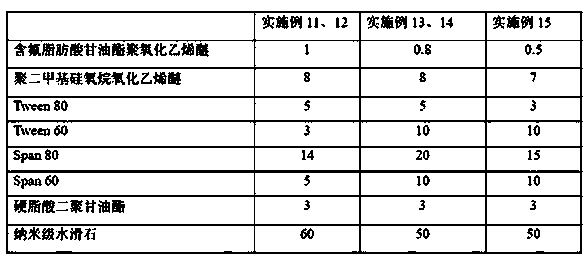

[0051] The preparation method of durable anti-fog and non-drip polyvinyl chloride greenhouse film is the intercalation-material mixing-calendering process of anti-fog agent and non-drip agent and slow-release agent:

[0052] Anti-fogging agent and non-drip agent and slow-release agent intercalation process: add nano-slow-release agent (hydrotalcite), composite anti-fogging agent, and composite non-drip agent to anhydrous ethanol according to the formula ratio into a three-necked bottle with condenser reflux In the method, the mass ratio of the nano-sustained-release agent to absolute ethanol is 1:9, heated to 50°C, and reacted with strong stirring for 2 hours, filtered, dried in a vacuum oven, and ground.

[0053] Material mixing process: mix polyvinyl chloride resin, stabilizer, plasticizer, lubricant, antioxidant, light stabilizer, compound anti-fog and n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com