Ion pre-embedded two-dimensional layered material intercalation electrode and preparation method and application thereof

A two-dimensional layered, ionic technology, used in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as low cycle performance and low capacity, achieve high power density, improve structure and interface, and optimize structure and interface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a preparation method for constructing a high-performance intercalation electrode by pre-embedding two-dimensional layered materials with electrochemical ions. The method comprises the following steps:

[0034] (1) Preparation of two-dimensional layered material working electrode:

[0035] First, the two-dimensional layered material, conductive agent and binder are mixed evenly according to a certain ratio, and N-methylpyrrolidone (NMP) is added for stirring to form a fluid electrode slurry, and then the electrode slurry is evenly coated Made on the current collector, weigh the mass of the coated electrode active material and dry it in vacuum; in addition, some two-dimensional materials can realize the construction of self-supporting electrodes, which can be directly used as working electrodes for electrochemical ion pre-embedding;

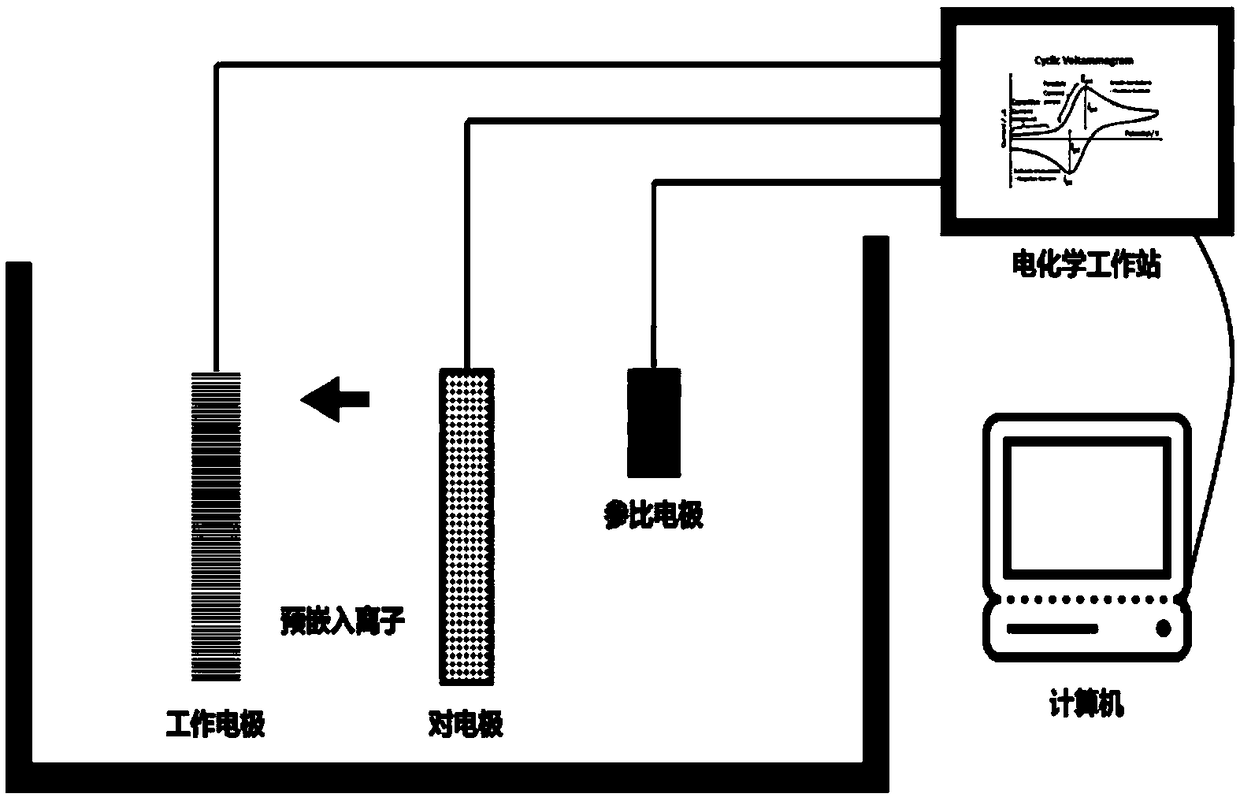

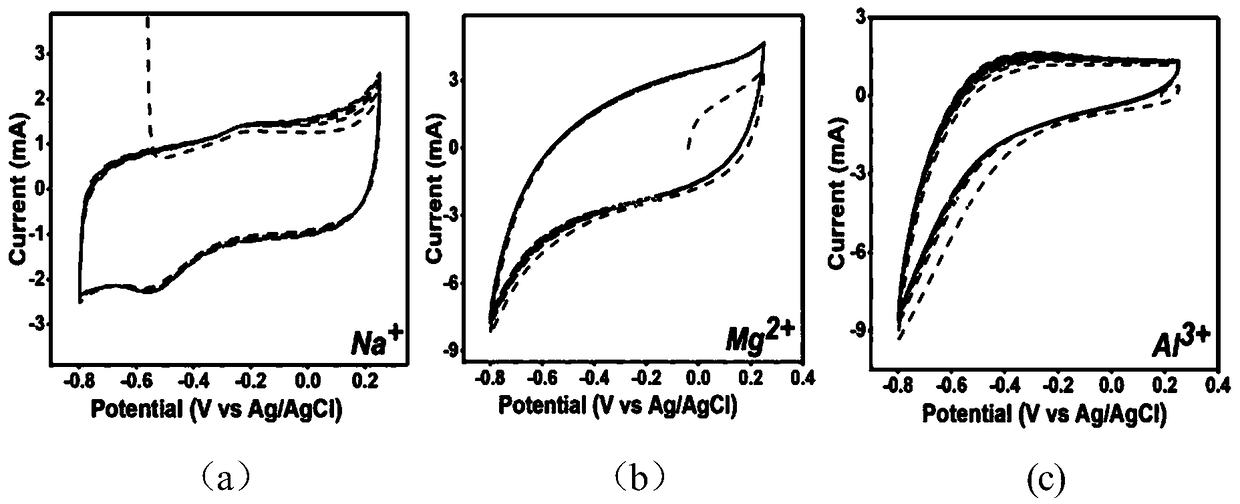

[0036] (2) Selection of ion pre-intercalation electrochemical reaction system:

[0037] The ion pre-intercalation e...

Embodiment 1

[0051] A method for constructing a high-performance intercalation electrode by pre-embedding two-dimensional layered materials with electrochemical ions, specifically comprising the following steps:

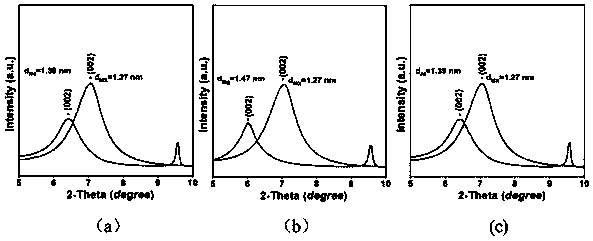

[0052] (1) Preparation of MXene electrodes

[0053] The two-dimensional layered active material MXene, the conductive agent Super-P, and the binder polyvinylidene fluoride PVDF were ground in a mass ratio of 8:1:1 to make them uniform. The mass of MXene was 80 mg, and the mass ratio of the conductive agent Super-P was The mass is 10 mg, the mass of the binder polyvinylidene fluoride PVDF is 10 mg, and N-methylpyrrolidone (NMP) is added for stirring, and the ratio of the volume of N-methylpyrrolidone (NMP) to the mass of the active substance is 200ml / g , stirred for more than 24 hours to form a fluid electrode slurry, and then evenly brush the electrode slurry on the carbon paper current collector with a brush, and after drying, use the mass of the coated electrode active material...

Embodiment 2

[0066] A preparation method for constructing a high-performance intercalation electrode by ion electrochemical pre-embedded two-dimensional layered material, specifically comprising the following steps:

[0067] (1) Preparation of MXene electrodes

[0068]The two-dimensional layered active material MXene, the conductive agent Super-P, and the binder polyvinylidene fluoride PVDF were ground in a mass ratio of 8:1.5:1.5 to make them uniform. The mass of MXene was 160 mg, and the mass ratio of the conductive agent Super-P was The mass is 30 mg, the mass of the binder polyvinylidene fluoride PVDF is 30 mg, and N-methylpyrrolidone (NMP) is added for stirring, and the ratio of the volume of N-methylpyrrolidone (NMP) to the mass of the active substance is 200ml / g , stirred for more than 26 hours to form a fluid electrode slurry, and then evenly brush the electrode slurry on the current collector of the Ti sheet with a brush. Weigh and then place in a vacuum oven at 60°C for vacuum d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com