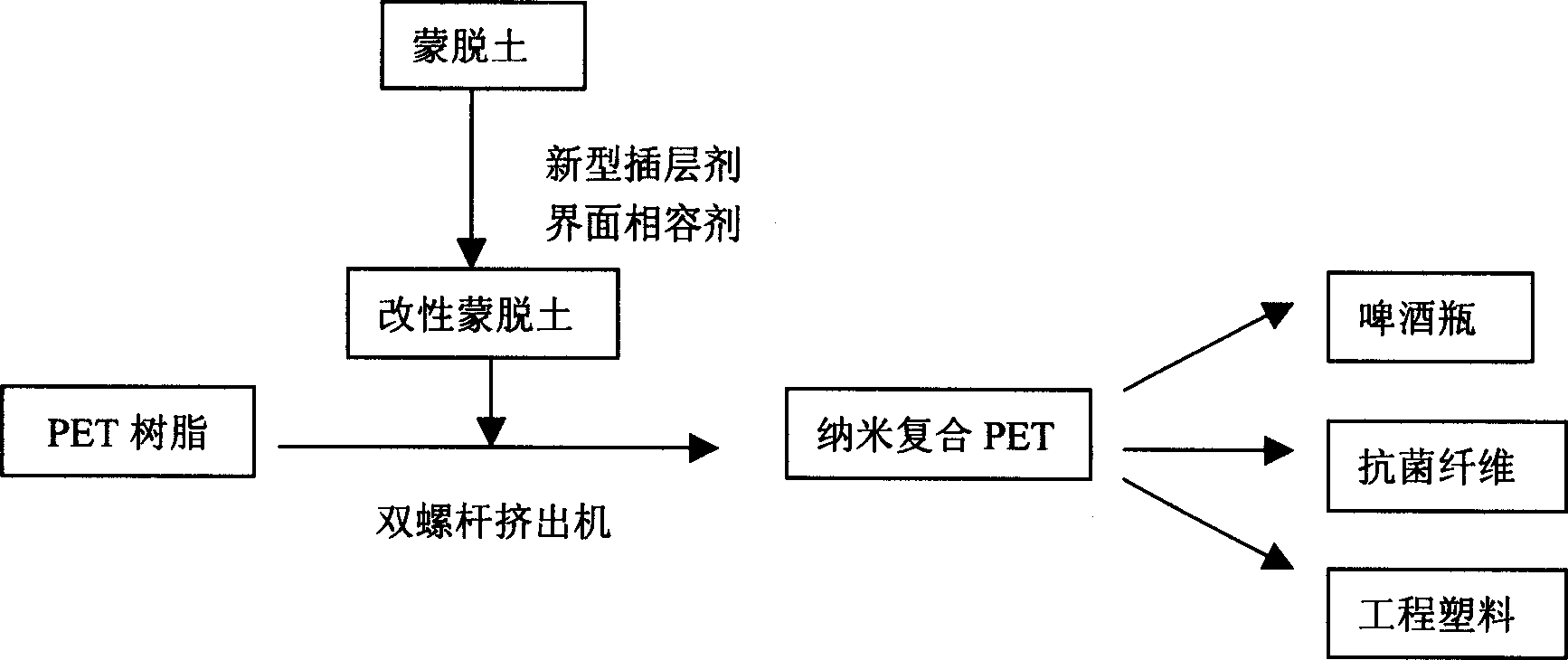

Polyester/lamellar silicate nano composite material and preparation method thereof

A nano-composite material and layered silicate technology, applied in the field of polyester composite materials, can solve the problems of large product limitations, low melt strength, affecting product color and luster, and achieve a wide variable range and good physical and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Add 5 g of montmorillonite with a total cation exchange capacity of 120 meq. / 100 g, add 200 ml of deionized water, stir at high speed for 0.5 hours to disperse evenly, and obtain a stable suspension, then mix 0.6 ml of concentrated hydrochloric acid with 2.6 g of hexadecane Add trimethylammonium bromide to 100ml deionized water, add the latter slowly to the suspension, continue stirring at high speed and raise the temperature to 80°C, centrifuge after 2 hours, discard the supernatant, and redisperse the filter cake in 300ml In ethanol, re-stir, heat up to reflux, add 1g epoxy 628 (Shell company), reflux 1 hour, discard the supernatant after centrifugation, filter cake is air-dried at 50 ℃ for 10 hours, then it is in 80 ℃ vacuum drying for 3 hours, then mixed with 500g PET dried at 120 ℃ for 5 hours at high speed, and blended and granulated with a Φ30 twin-screw extruder to obtain a PET / layered silicate nanocomposite material. In the composite material, the sca...

Embodiment 2

[0031] Example 2 Add 5 g of montmorillonite with a total cation exchange capacity of 120 meq. / 100 g, add 200 ml of deionized water, stir at high speed for 0.5 hours to disperse evenly, and obtain a stable suspension, then mix 0.6 ml of concentrated hydrochloric acid with 2.6 g of hexadecane Add trimethylammonium bromide to 100ml deionized water, add the latter slowly to the suspension, continue stirring at high speed and raise the temperature to 80°C, centrifuge after 2 hours, discard the supernatant, and redisperse the filter cake in 200ml In ethanol, stir again, heat up to 60 ° C, add 0.2 g of silane coupling agent (Z6030 of Dow Corning Company), stir for 1 hour, discard the supernatant after centrifugation, and dry the filter cake at 50 ° C for 10 hours. It was vacuum-dried at 80° C. for 3 hours, then mixed with 500 g of PET dried at 120° C. for 5 hours at high speed, and blended and granulated with a Φ30 twin-screw extruder to obtain a PET / layered silicate nanocomposite mat...

Embodiment 3

[0032] Example 3 First, 10 g of montmorillonite with a total capacity of cation exchange of 100 meq. / 100 g was added to 200 ml of deionized water, stirred at a high speed for 0.5 hours to disperse evenly to obtain a stable suspension, and then 1.0 ml of concentrated hydrochloric acid and 4.2 g of sixteen Add alkyltrimethylammonium bromide to 100ml of deionized water, slowly add the latter into the suspension, continue high-speed stirring and heat up to 80°C, centrifuge after 2 hours, discard the supernatant, and redisperse the filter cake in In 100ml ethanol, stir again, be warming up to reflux, add 1g epoxy 628 (Shell company), 0.2g silane coupling agent (Dow Corning's Z6030), reflux 1 hour, abandon supernatant after centrifugation, filter cake in Blast drying at 50°C for 10 hours, then vacuum drying at 80°C for 3 hours, then mixing with 500g PET dried at 120°C for 5 hours at high speed, blending and granulating with a Φ30 twin-screw extruder to obtain PET / layer silicate nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com