Preparation method of diallyl containing quaternary ammonium salt modified montmorillonoid

A bisallyl, montmorillonite technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., to achieve the effect of high positive charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

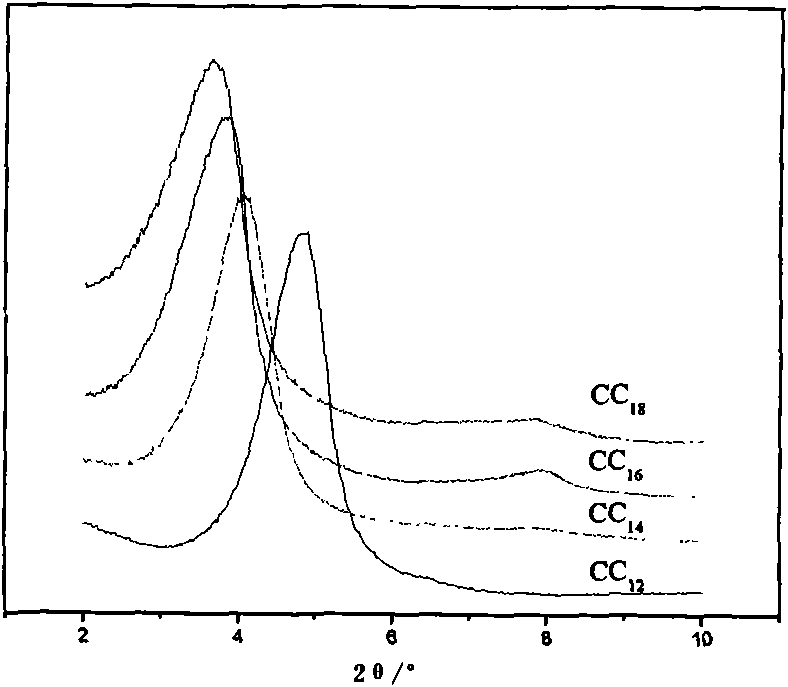

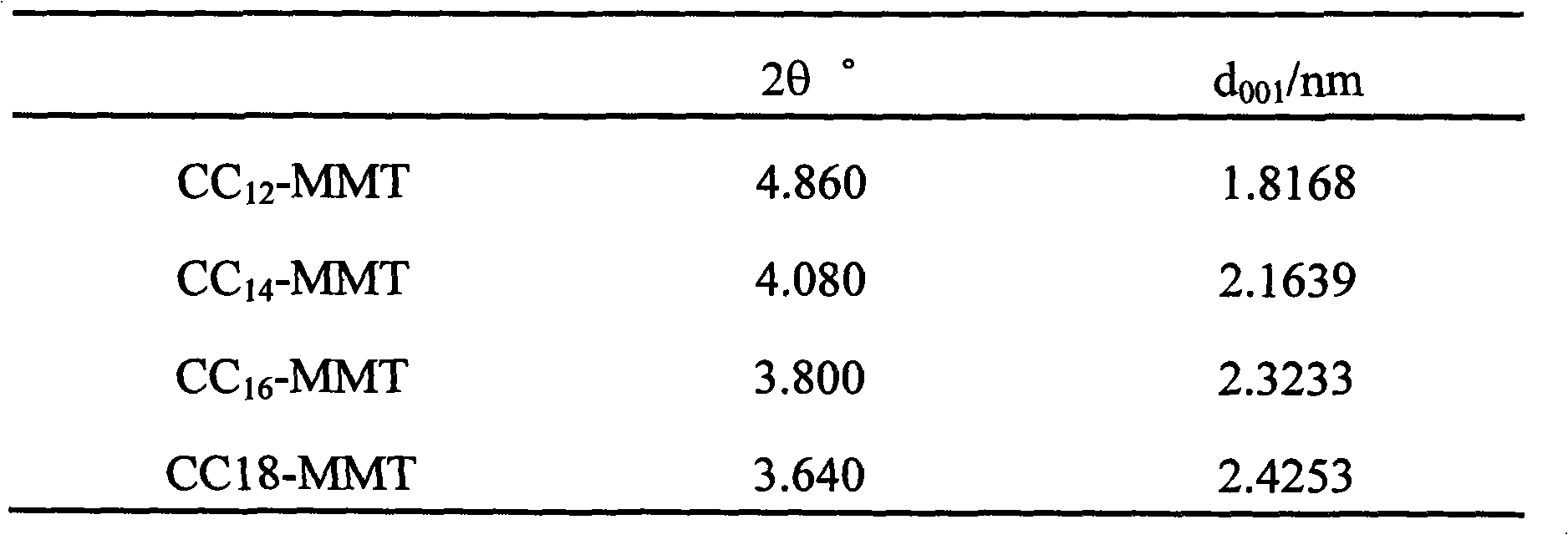

[0015] Example 1, add 100g of deionized water into a 250mL three-neck flask, slowly add 3.00g of montmorillonite, and stir at a slow speed for 20min; Diallylmethyl dodecyl ammonium bromide monomer, stirred for 15min, heated up to 75°C, after the temperature became constant, increased stirring speed, reacted for 6h, then suction filtered, washed with water several times, put in a vacuum oven at 80°C Dry for 24 hours to obtain bisallylmethyl dodecyl ammonium bromide modified montmorillonite.

Embodiment 2

[0016] Example 2, add 100g of deionized water into a 250mL three-necked flask, slowly add 2.00g of montmorillonite, and stir at a slow speed for 15min; Diallylmethyltetradecyl ammonium bromide monomer, stirred for 10min, heated up to 80°C, after the temperature was constant, increased the stirring speed, reacted for 5h, then filtered with suction, washed with water for several times, and placed in a vacuum oven at 80°C Dry for 24 hours to obtain bisallylmethyltetradecylammonium bromide modified montmorillonite.

Embodiment 3

[0017] Example 3, add 100g of deionized water into a 250mL three-necked flask, slowly add 6.00g of montmorillonite, and stir at a slow speed for 30min; Diallyl methyl hexadecyl ammonium bromide monomer, stir for 20min, heat up to 90°C, after the temperature is constant, increase the stirring speed, react for 4h, then filter with suction, wash with water several times, put in a vacuum oven at 80°C Dry for 24 hours to obtain bisallyl methyl hexadecyl ammonium bromide modified montmorillonite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com