Heat-conducting graphite paper and preparation method thereof

A technology of thermally conductive graphite and flake graphite, applied in graphite, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low thermal conductivity of thermally conductive paper and difficulty in meeting the technical application requirements of high-power electronic products, and achieve low cost and increased surface area. The effect of smoothness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

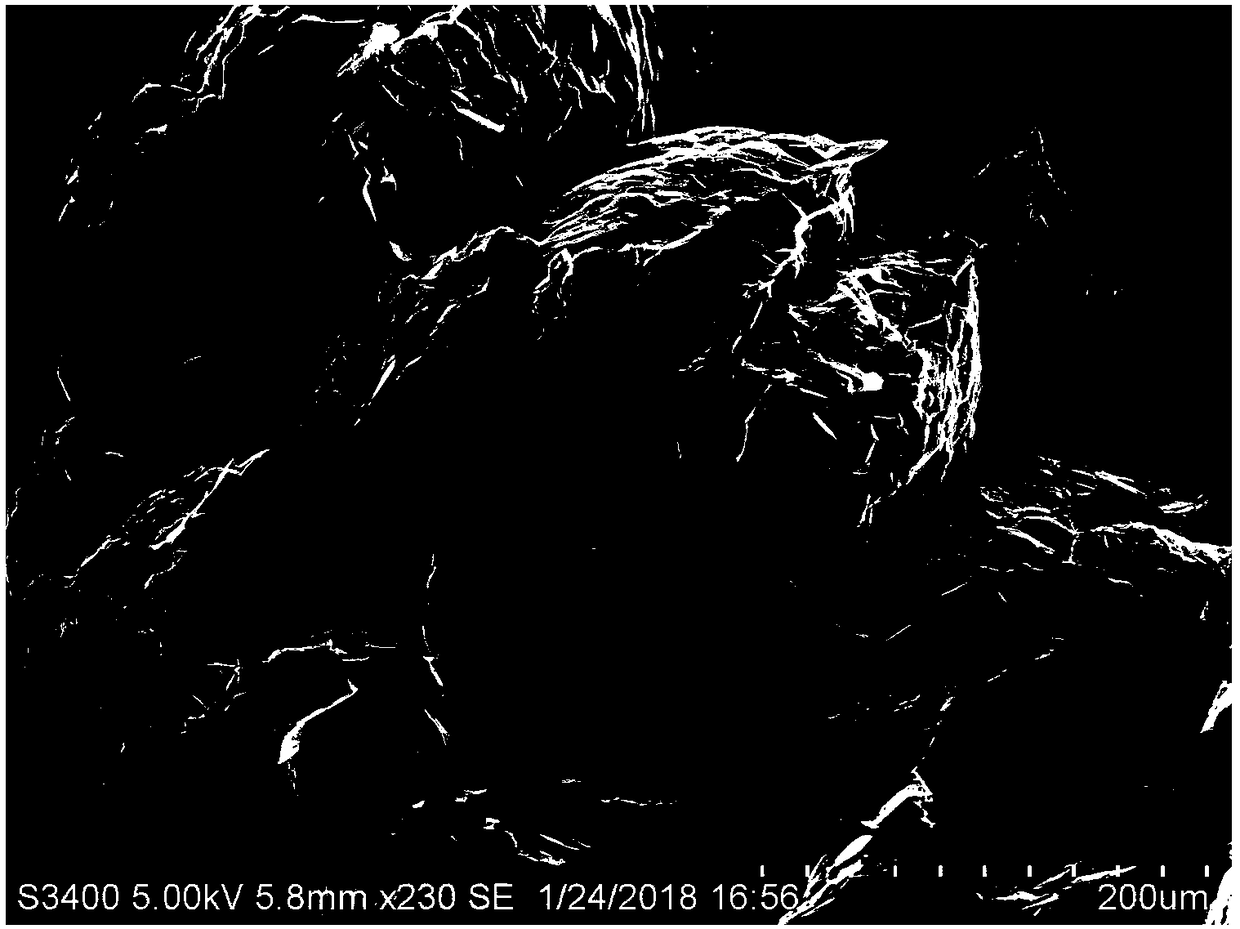

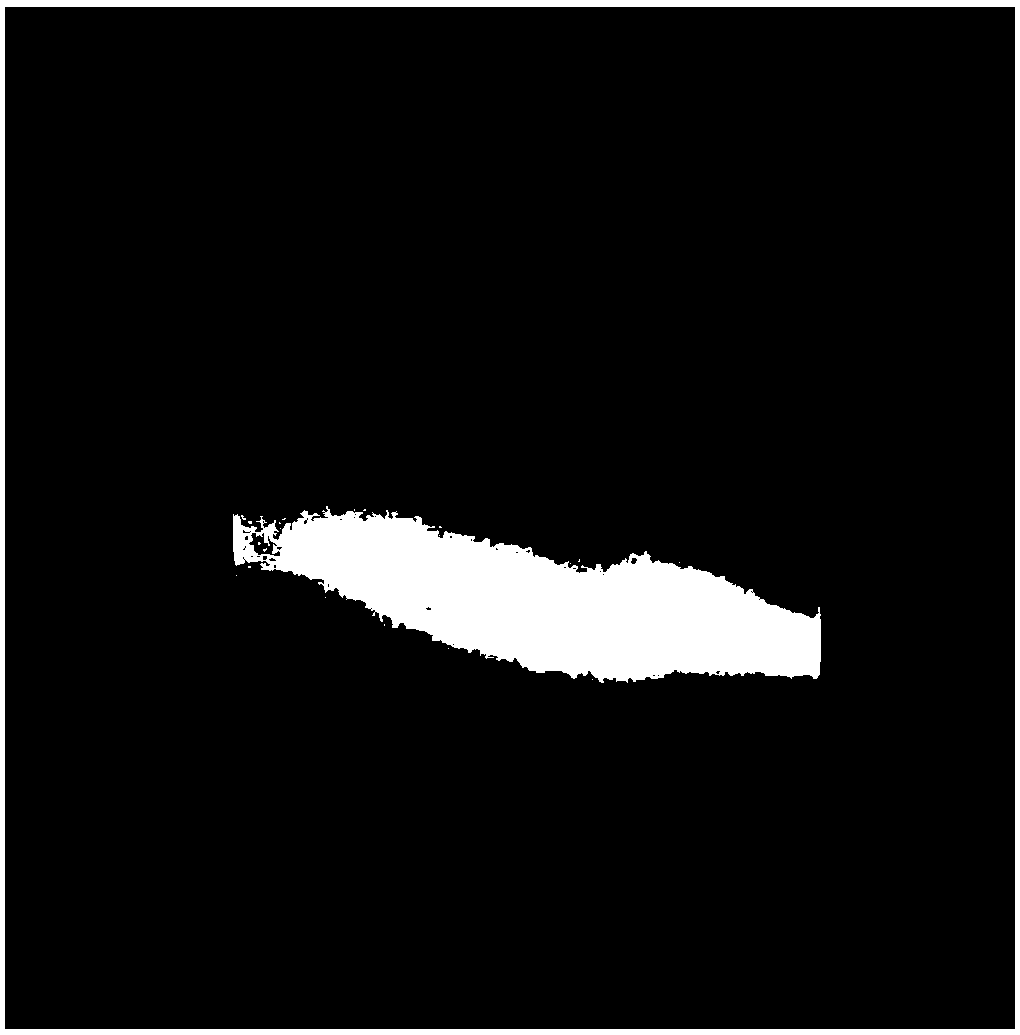

Image

Examples

preparation example Construction

[0015] The invention provides a preparation method of heat-conducting graphite paper. The preparation method comprises the following steps:

[0016] S1, mixing graphite flakes with concentrated sulfuric acid solution, performing an oxidation reaction to obtain a first mixture, wherein the mass ratio of graphite flakes to concentrated sulfuric acid solution is 1:(2.5~3.0), and the sulfuric acid in the concentrated sulfuric acid solution The mass fraction is 95% to 98%;

[0017] S2, adding an oxidizing agent to the first mixture to perform an oxidative intercalation reaction to obtain a second mixture, wherein the oxidizing agent is a nitric acid solution, and the mass ratio of the nitric acid solution to the flake graphite is 1:5 to 1: 10. The mass fraction of nitric acid in the nitric acid solution is 50% to 68%;

[0018] S3, washing the second mixture with water to obtain a preform;

[0019] S4, placing the preform in a chamber, firstly evacuating the chamber, then introdu...

Embodiment (1

[0035] The preparation method of heat-conducting graphite paper described in this embodiment comprises the following steps:

[0036] (1) The graphite ore is purified and pulverized to obtain flake graphite. Put flake graphite and concentrated sulfuric acid solution in a mixer for 15 minutes, wherein the mass of flake graphite is 150±5Kg, the quality of concentrated sulfuric acid solution is 378±5Kg, and the sulfuric acid concentration is 98%.

[0037] (2) Pour 30±0.5Kg of nitric acid solution with a mass fraction of about 58% into the mixer, stir for 30 minutes, and let stand for 60 minutes to obtain the second mixture.

[0038] (3) washing the second mixture with water until the pH value is 6-7, and drying to obtain a preform.

[0039] (4) The preform is placed in a chamber, the chamber is first evacuated, and then an inert gas composed of nitrogen and helium with a volume ratio of 95:5 is continuously introduced into the chamber. The feed rate of the inert gas is 3×10 6 s...

Embodiment (2

[0059] The preparation method of heat-conducting graphite paper described in this embodiment comprises the following steps:

[0060] (1) The graphite ore is purified and pulverized to obtain flake graphite. The graphite flakes and the concentrated sulfuric acid solution are placed in a mixer for 10 minutes, wherein the graphite flakes have a mass of 150±5Kg, and the concentrated sulfuric acid solution with a mass fraction of about 95% has a mass of 420±5Kg.

[0061] (2) 20±0.5Kg of nitric acid solution with a mass fraction of about 68% was injected into the mixer, stirred for 30 minutes, and left to stand for 50 minutes to obtain the second mixture.

[0062] (3) washing the second mixture with water until the pH value is 6-7, and drying to obtain a preform.

[0063] (4) The preform is placed in a chamber, the chamber is first evacuated, and then an inert gas composed of nitrogen and helium with a volume ratio of 90:10 is continuously introduced into the chamber. The feed rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com