Buried high-temperature-resistant shielding cable

A shielded cable, high temperature resistant technology, applied in the field of buried high temperature resistant shielded cable, can solve the problems of cable core wire damage, cable connection trouble, cable bearing capacity is not good, etc., to improve the service life, wide range of use, Avoid the effect of abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

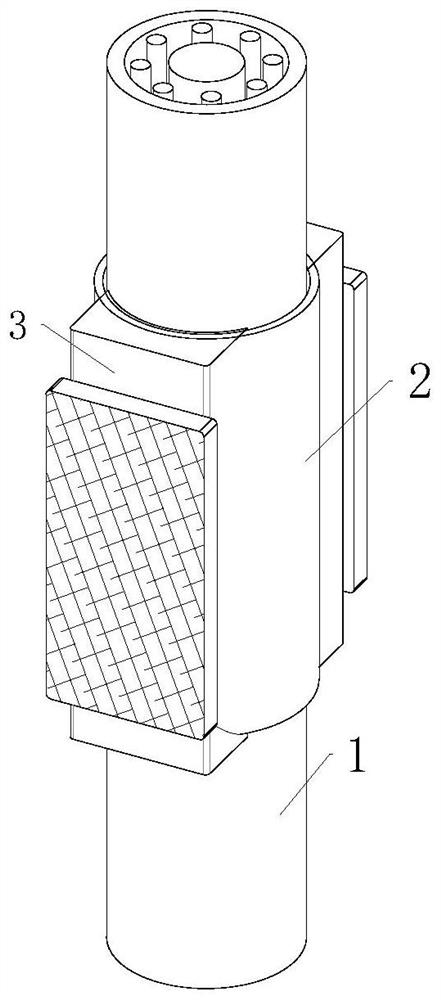

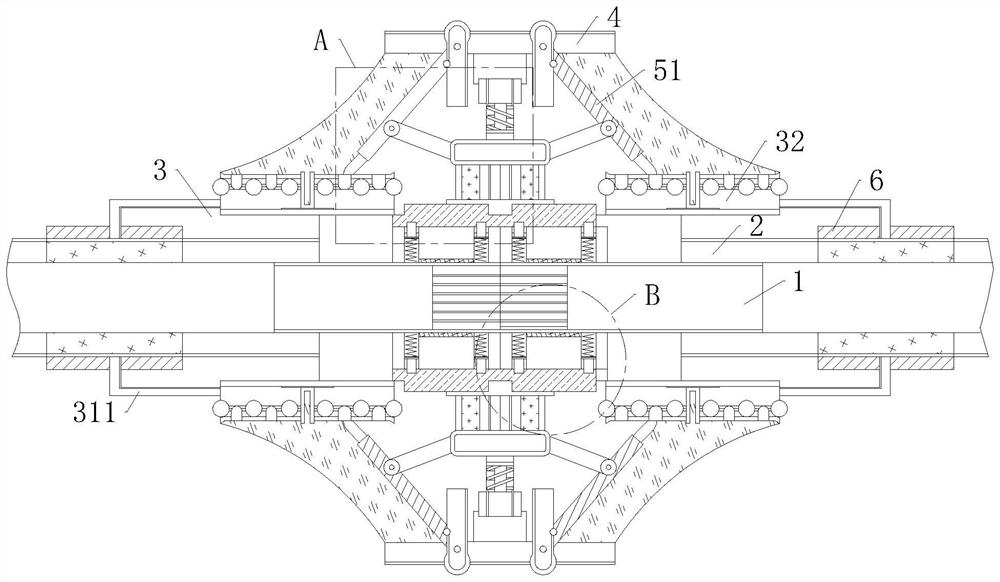

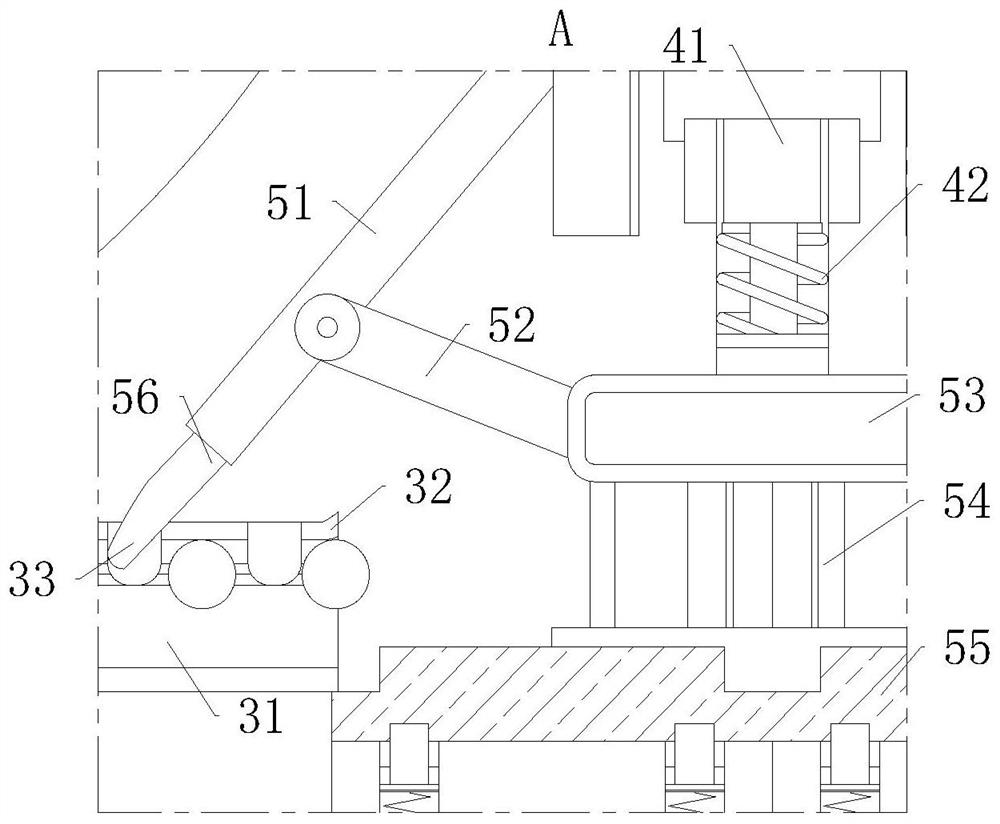

[0030] like figure 1 , figure 2 , image 3 , Figure 5 and Image 6 As shown in the embodiment of the present invention, a buried high temperature resistant shielded cable includes a cable body 1 and a connecting seat 2. The cable body 1 runs through the interior of the connecting seat 2, and the connecting A support base 3 is fixedly connected to the outer surface of the base 2, and a shielding base 4 is fixedly connected to the inside of the support base 3. The side surface of the shielding base 4 is provided with a connecting component 5, and one side of the connecting component 5 is connected There is an airtight assembly 6; in the present invention, when connecting two cables, the two cable heads are passed into the connection seat 2, and then the connection assembly 5 is used to connect the cables; the airtight assembly 6 can seal the cable connection. shield.

[0031] like figure 2 , image 3As shown in the figure, the connecting assembly 5 includes a toggle ro...

Embodiment 2

[0037] like figure 2 and Figure 4 As shown, Comparative Example 1, wherein another embodiment of the present invention is: the middle part of the outer surface of the connection seat 2 is fixedly connected with a gas transmission seat 21, and the interior of the gas transmission seat 21 is fixedly connected with a plurality of The heat supply pipe 22, the inside of the gas supply seat 21 is fixedly connected with a heat-conducting rod 23, the inside of the heat supply pipe 22 is provided with a piston rod 24, and the surface of the piston rod 24 is fixedly connected with a top rod 25, the said The surface of the ejector rod 25 is fixedly connected with a closed ring 26, and one side of the piston rod 24 is provided with a tension spring 27; when the electrical resistance of the cable joint increases due to external reasons, and the joint generates heat, the heat will be transmitted to the heat conduction. On the surface of the rod 23, when the heat is too high, the gas insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com