Lipophilic graphene and preparation method thereof

A lipophilic, graphene technology, applied in graphene, petroleum industry, lubricating compositions, etc., can solve problems such as poor dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

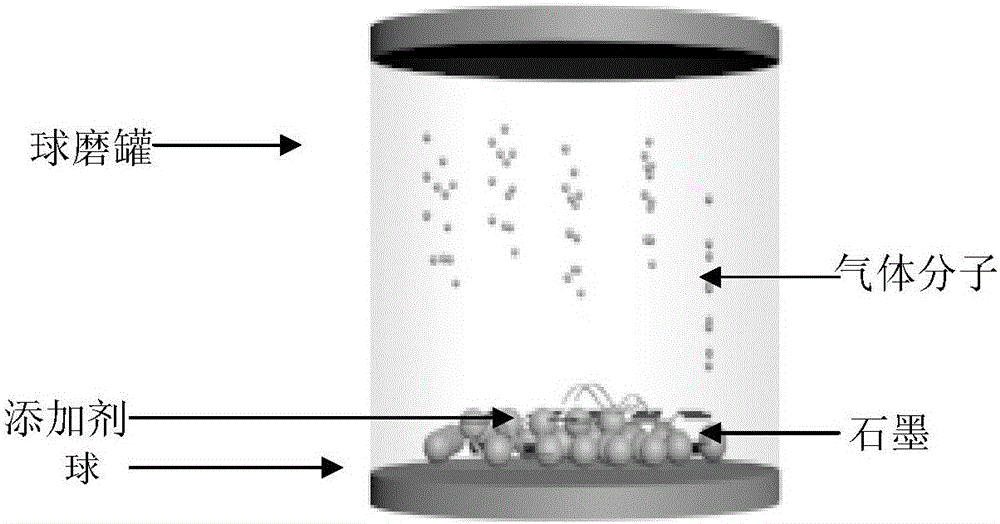

[0033] The present embodiment provides a kind of preparation method of lipophilic graphene, it comprises the following steps:

[0034] Expanded graphite powder, oleic acid and stearic acid are added to a ball mill jar, wherein the mass ratio of stearic acid to oleic acid is 3:5, and the mass ratio of expanded graphite powder to oleic acid is 10:1, and the ball mill jar is closed;

[0035] Introduce CO through the inlet pipeline on the ball mill tank 2 Gas, adjust the intake volume to control the pressure at 10MPa;

[0036] Set the reaction temperature to 40°C (the pressure in the tank will change during the heating process, adjust the outlet valve to keep the pressure at 10MPa), when the temperature reaches 40°C, set the rotation speed to 300rpm, and the reaction time is 2 hours;

[0037] After the reaction is completed, the gauge pressure in the tank is released to 0MPa through the release valve, and the reaction device (schematic diagram is as follows: figure 1 Shown) can ...

Embodiment 2

[0044] The present embodiment provides a kind of preparation method of lipophilic graphene, it comprises the following steps:

[0045] Add expanded graphite powder, oleylamine and petroleum ether into the ball mill jar, wherein the mass ratio of graphite powder to oleylamine is 10:1, petroleum ether is added at 1mL / (g graphite powder), and the ball mill jar is closed;

[0046] Introduce CO through the inlet pipeline on the ball mill tank 2 Gas, adjust the intake volume to control the pressure at 10MPa;

[0047]Set the reaction temperature to 50°C (the pressure in the tank will change during the heating process, adjust the outlet valve to keep the pressure at 10MPa), when the temperature reaches 50°C, set the rotation speed to 300rpm, and the reaction time is 2 hours;

[0048] After the reaction is finished, release the pressure through the vent valve until the gauge pressure in the tank is 0MPa, and the reaction device can be opened after cooling to room temperature under air...

Embodiment 3

[0051] The present embodiment provides a kind of preparation method of lipophilic graphene, it comprises the following steps:

[0052] Add flake graphite, oleylamine and petroleum ether to the ball milling jar, wherein the mass ratio of graphite to oleylamine is 10:1, petroleum ether is added at 1mL / (g graphite powder), and the ball milling jar is closed;

[0053] Inject N through the inlet pipeline on the ball mill tank 2 , adjust the air intake to keep the pressure at 4MPa; set the reaction temperature to 35°C (the pressure in the tank will change during the heating process, adjust the outlet valve to keep the pressure at 4MPa), when the temperature reaches 35°C, set the speed to 900rpm , the reaction time is 4 hours;

[0054] After the reaction is over, release the pressure through the release valve until the gauge pressure in the tank is 0 MPa, and the reaction device can be opened after cooling to room temperature under air conditions, and the product can be taken out; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com