Preparation of low temperature expandable graphite

A technology of expanded graphite and low temperature, applied in the field of preparation of expandable graphite, can solve the problems of high expansion temperature and limit the application range of expandable graphite, and achieve the effects of high safety, low equipment requirements and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

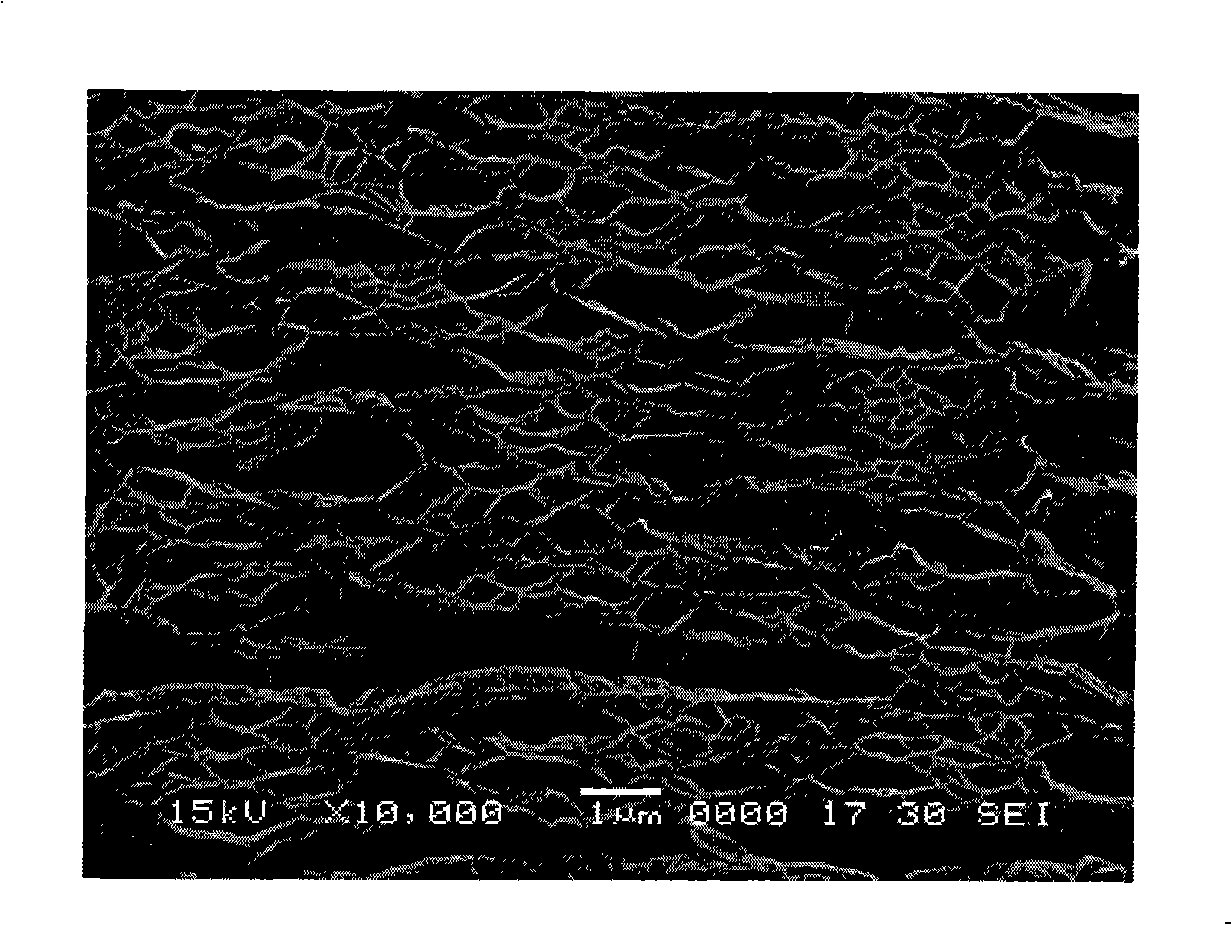

[0027] Take 3-25g of natural flake graphite, 3-30g of potassium permanganate, and 25-300ml of concentrated sulfuric acid. First add concentrated sulfuric acid into a three-necked flask, add natural flake graphite while stirring, slowly add potassium permanganate into the flask after stirring, control the temperature of the reaction solution at 30°C to 45°C, and oxidize for one hour. After the reaction, continuously add 100-800ml of deionized water into the flask, and control the temperature below 90°C. After keeping it for one hour, wash the reaction product until neutral, and finally use water exchange method to make water as the main intercalation agent , filtered, and baked at 50°C for 24 hours. The prepared expandable graphite begins to expand at 160°C, and the expansion volume at 200°C is 150ml / g (see the SEM image after it expands at 180°C figure 1 ).

Embodiment 2

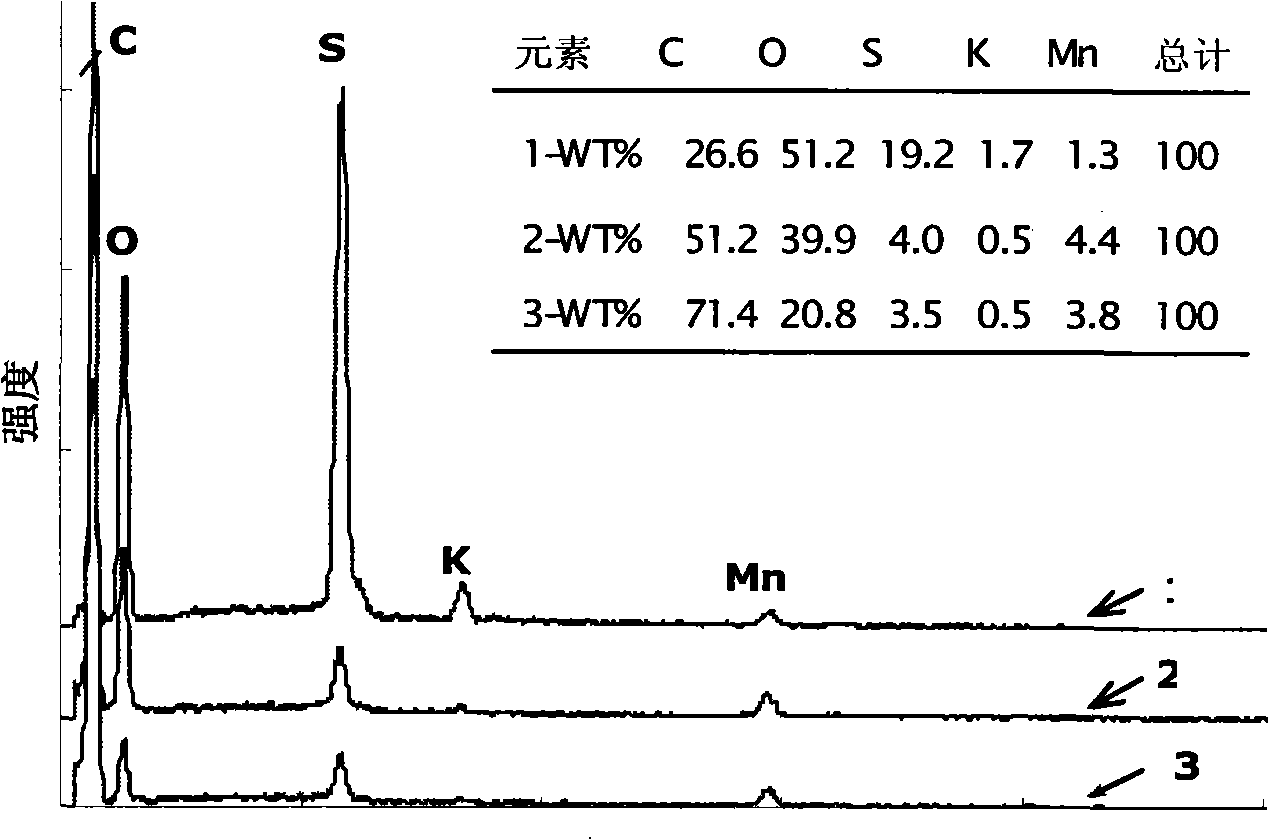

[0029] Take 3-25g of natural flake graphite, 5-38g of potassium permanganate, 40-500ml of concentrated sulfuric acid, first add concentrated sulfuric acid into a three-necked flask, add natural flake graphite while stirring, and slowly add permanganate into the flask after stirring evenly Potassium, the temperature of the reaction solution is controlled at 30°C to 50°C, and the oxidation reaction takes two and a half hours. After the reaction is completed, continuously add 150 to 1200ml of deionized water into the flask, and keep the temperature below 90°C for two hours. , wash the reaction product to neutrality. Then, the concentrated sulfuric acid between graphite layers was replaced by water exchange method, water was used as the main intercalation agent, filtered, and baked at 90°C for 24 hours. The target object (expandable graphite) was obtained. It begins to expand at 160°C, and the expansion volume at 200°C is 200ml / g; the EDS energy spectrum test spectrum of the expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com