Cathode and electrolyte of aqueous solution lithium ion secondary battery, and battery

A secondary battery, aqueous solution technology, applied in secondary batteries, battery electrodes, solutions of liquid solvents at room temperature, etc., can solve the problems of concentration polarization, difficult to make practical batteries, and electrolyte cross-contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

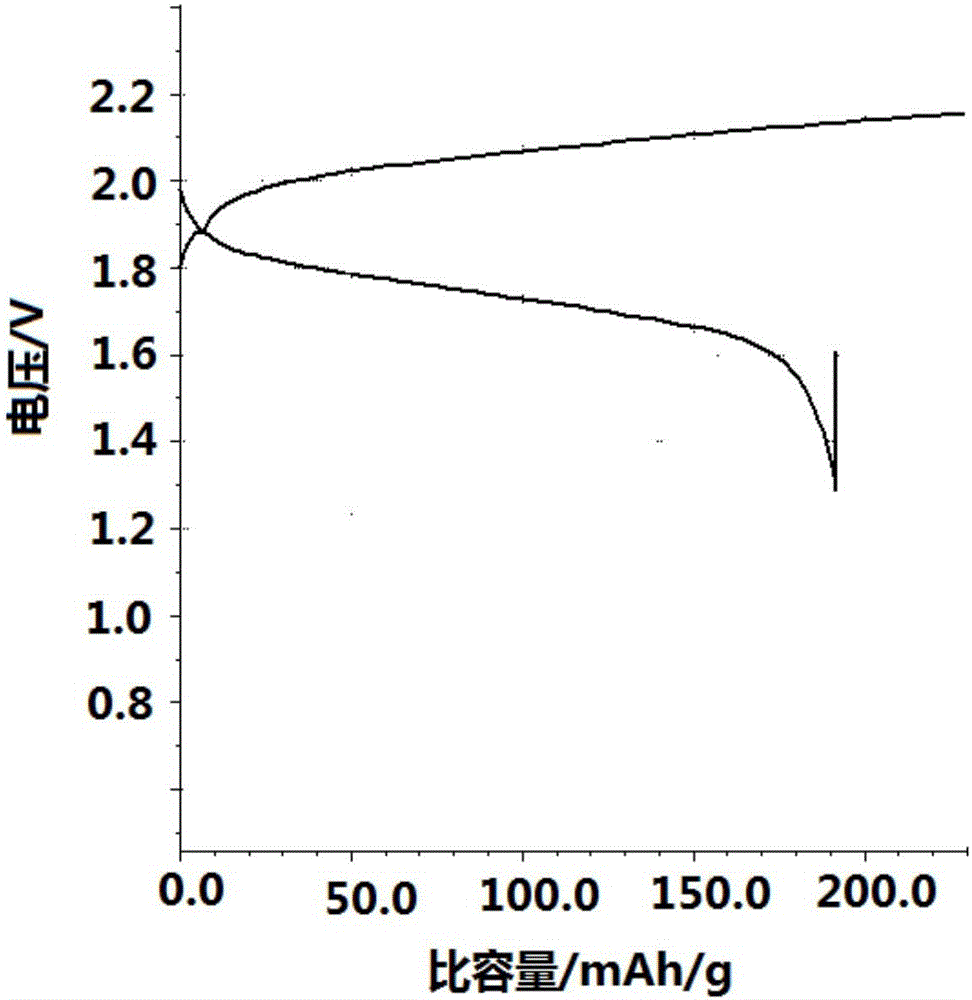

[0045] This embodiment describes an aqueous lithium ion secondary battery using zinc tartrate crystal hydrate as the negative electrode active material, lithium manganate as the positive electrode active material, and an aqueous solution of lithium tartrate as the electrolyte.

[0046] Preparation of the negative electrode: Weigh 2 grams of zinc tartrate crystalline hydrate, 0.15 grams of carbon nanotubes, and 0.1 grams of acetylene black, and put them in an agate mortar, mix them, and grind them. Weigh 0.15 grams each of the adhesive PVDF and LA132, dissolve it in the NMP solvent, heat and stir evenly, pour the mixed and finely ground mixture into the above solvent and stir to make a negative electrode slurry. The anode current collector is made of 0.1mm zinc foil, washed with acetone and deionized water alternately when using, and then the anode slurry is evenly coated on the zinc foil with a glass rod, dried at 80℃, rolled and dried at 120℃ As a negative electrode, the load is...

Embodiment 2

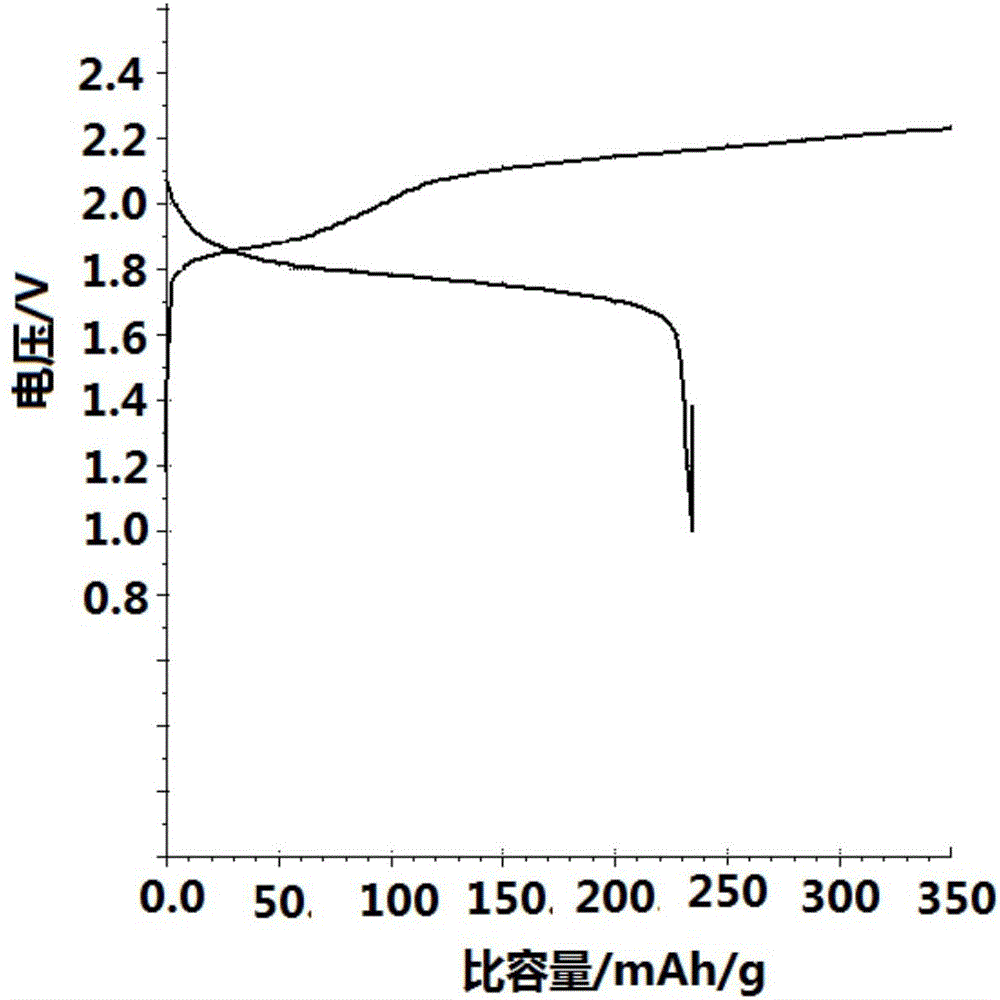

[0053] This embodiment describes an aqueous lithium ion secondary battery using zinc tartrate as the negative electrode active material, lithium cobaltate as the positive electrode active material, and lithium tartrate aqueous solution as the electrolyte.

[0054] Preparation of the negative electrode: Weigh 2 grams of zinc tartrate, 0.15 grams of activated carbon, and 0.1 grams of acetylene black, and put them in an agate mortar, mix and grind them. Weigh 0.15 grams each of the adhesive PVDF and LA132, dissolve it in the NMP solvent, heat and stir evenly, pour the mixed and finely ground mixture into the above solvent and stir to make a negative electrode slurry. The negative electrode current collector is 0.2 mm thick foamed silver, which is washed alternately with acetone and deionized water during use, and then the negative electrode slurry is evenly coated on the foamed silver with a glass rod, dried at 80°C, rolled, and dried at 120°C Manufactured into a negative electrode ...

Embodiment 3

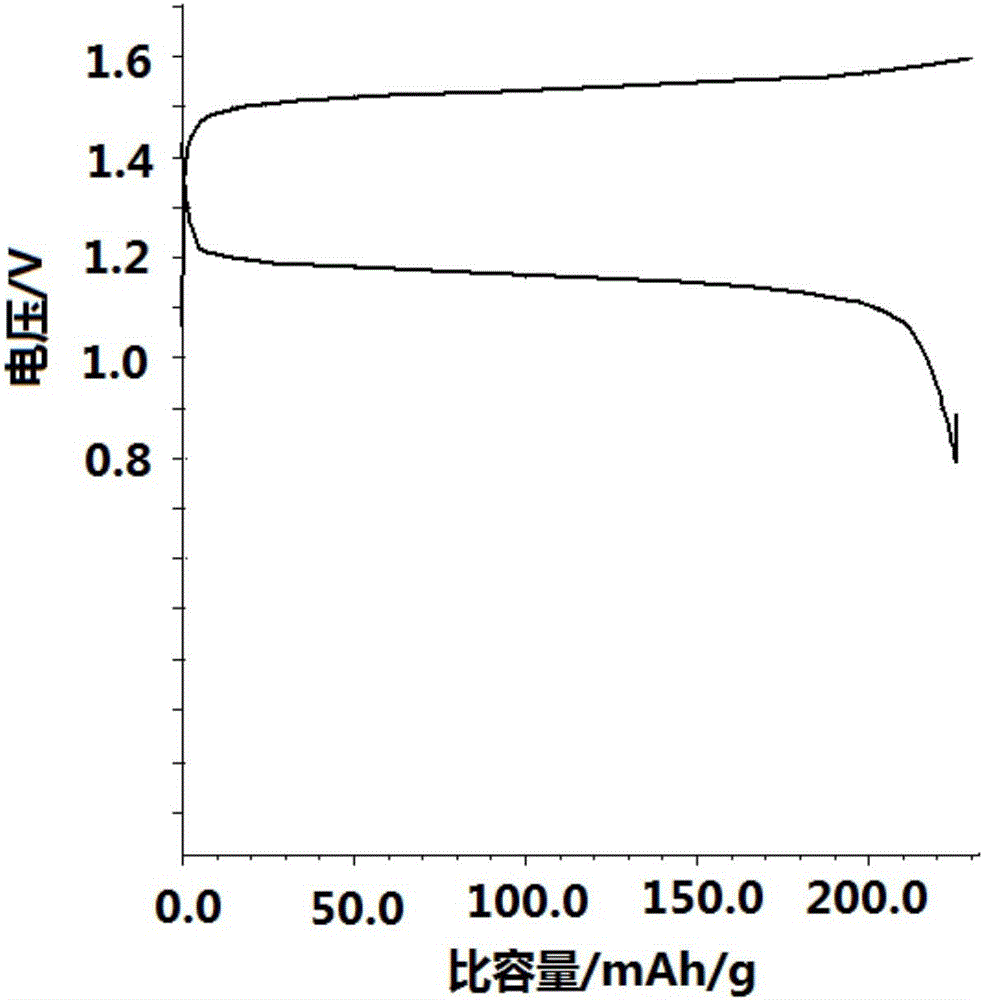

[0061] This embodiment describes an aqueous lithium ion secondary battery using zinc tartrate as the negative electrode active material, lithium iron phosphate as the positive electrode active material, and lithium tartrate aqueous solution as the electrolyte.

[0062] Preparation of the negative electrode: Weigh 2 grams of zinc tartrate, 0.15 grams of activated carbon, and 0.1 grams of acetylene black, and put them in an agate mortar, mix and grind them. Weigh 0.15 grams each of the adhesive PVDF and LA132, dissolve it in the NMP solvent and heat and stir evenly, pour the mixed and ground mixture into the above solvent and stir to make a negative electrode slurry. The anode current collector is made of zinc foil with a thickness of 0.1 mm. It is washed alternately with acetone and deionized water during use, and then the anode slurry is evenly coated on the zinc foil with a glass rod, dried at 80°C, rolled and dried at 120°C Cut into 1cm×2cm negative electrode sheet, load capaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com