Nano microcrystalline cellulose/layered silicate hybrid and preparation method thereof

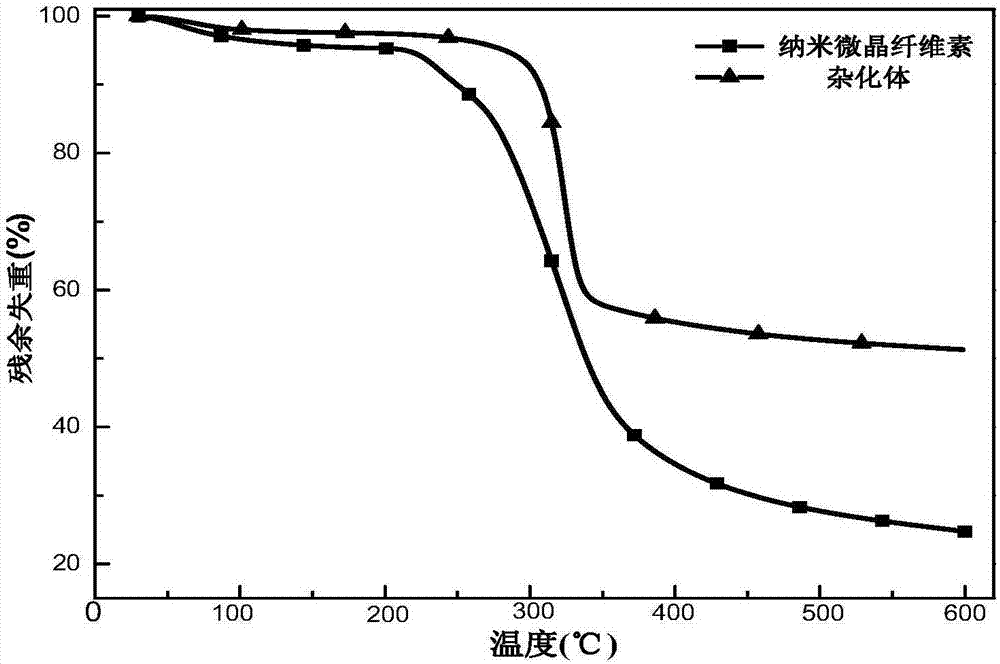

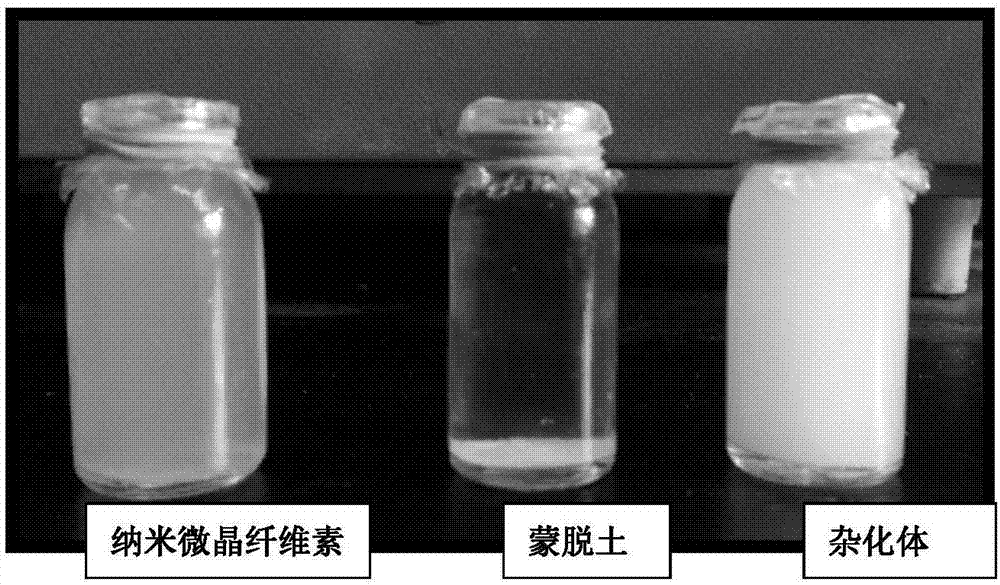

A layered silicate and nano-crystal technology, applied in the field of nano-materials, can solve the problems of poor thermal stability of nano-microcrystalline cellulose, achieve thermal stability and excellent mechanical properties, reduce agglomeration, and improve thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The cotton straw is hydrolyzed with concentrated sulfuric acid to obtain the cotton straw nano microcrystalline cellulose, and the nano microcrystalline cellulose powder is obtained after freeze-drying.

[0030] In terms of parts by mass, disperse 1.5 parts of cotton straw nano-microcrystalline cellulose hydrolyzed by sulfuric acid in 10 parts of deionized water and 15 parts of ethanol mixture, mix evenly, then add 0.1 part of potassium hydroxide, and ultrasonically stir at 30 °C After reacting for 1.5h, fluffy alkalized nanocellulose was prepared;

[0031] In terms of parts by mass, add 0.5 parts of (3-chloro-2-hydroxypropyl) trimethylammonium chloride solution with a mass fraction of 65%, and etherify at 50°C for 3 hours to prepare cationic nanocrystalline fibers Primer dispersion.

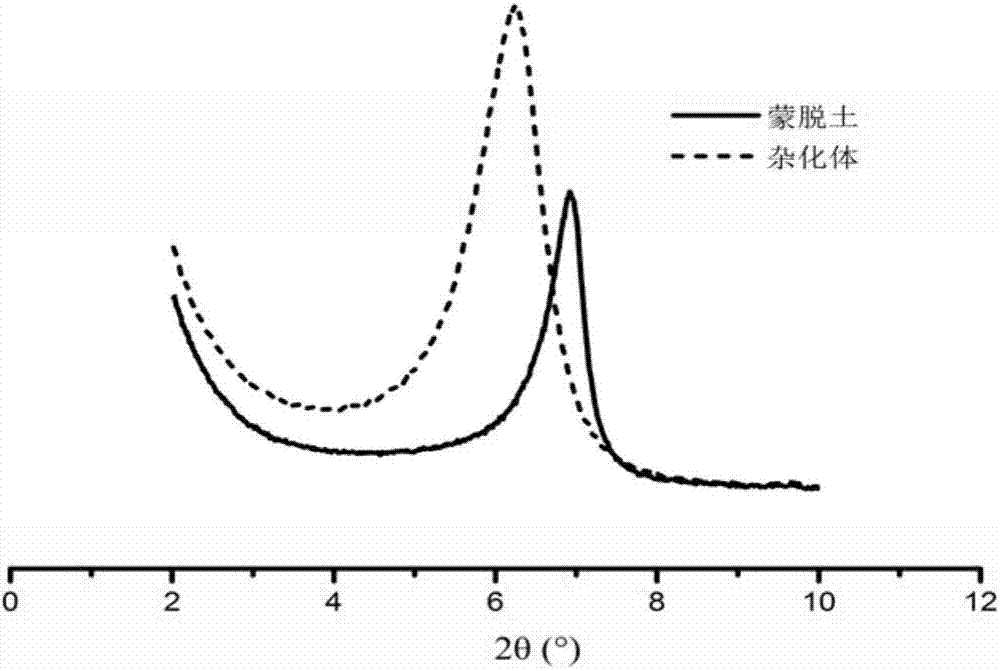

[0032] The sodium-based montmorillonite and the obtained dispersion were ultrasonically treated for 50 minutes at a pH of 8, and mixed uniformly to prepare a layered silicate with a mass...

Embodiment 2

[0044] The bagasse powder is hydrolyzed with concentrated sulfuric acid, and the nano-microcrystalline cellulose powder is obtained after freeze-drying.

[0045] In terms of parts by mass, 1 part of nanocrystalline cellulose was dispersed in 5 parts of deionized water and 15 parts of isopropanol solution, 0.15 parts of sodium hydroxide was added, and ultrasonic treatment was performed at room temperature for 1 h;

[0046] In terms of parts by mass, 0.6 parts of an aqueous solution of glycidyl trimethyl chloride of 65 wt % was added, and reacted in a water bath at 45° C. for 5 hours to obtain a cationized nanocellulose dispersion;

[0047] The sodium-based montmorillonite and the obtained dispersion were ultrasonically treated for 80 minutes at a pH of 10, and mixed uniformly to prepare a layered silicate with a mass percentage concentration of 1% and a cationic nanocellulose mass percentage concentration of 1%, and then Place it in an oil bath at 50° C. for 24 hours with magneti...

Embodiment 3

[0049] The wood powder is hydrolyzed with concentrated sulfuric acid, and the nano-microcrystalline cellulose powder is obtained after freeze-drying.

[0050] In terms of parts by mass, 1 part of nanocrystalline cellulose is dispersed in a mixed solution of 20 parts of deionized water and 10 parts of ethanol, 0.15 parts of sodium hydroxide is added, and ultrasonic treatment is performed at room temperature for 2 hours;

[0051] In terms of parts by mass, add 0.6 parts of 40wt% (3-chloro-2-hydroxypropyl) trimethylammonium chloride aqueous solution, and react for 5 hours at 45°C in a water bath to obtain a cationic nanocellulose dispersion;

[0052] The calcium-based montmorillonite and the obtained dispersion were ultrasonically treated for 50 minutes at a pH of 5, and mixed uniformly to prepare a layered silicate with a mass percentage concentration of 1% and a cationic nanocellulose mass percentage concentration of 1%, and then Place it in an oil bath at 50° C. for 24 hours w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com