Preparation method of sulfur-free expansible graphite

A technology of expanded graphite and natural flake graphite, applied in the field of materials, can solve the problems of polluted environment, difficult operation, and high reaction temperature of the preparation process, and achieve the effects of high expansion volume, improved corrosion resistance, and good intercalation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Mix 3g of natural flake graphite with a particle size of 32 mesh and a carbon content of 99.9% with 1.11g of potassium permanganate, then add 20.4mL of perchloric acid with a mass fraction of 70-72%, and keep stirring. After the reaction, soak in 50mL saturated dipotassium hydrogen phosphate solution at room temperature for 60min to carry out the second intercalation reaction; Dry for 24 hours to obtain sulfur-free expandable graphite; expand the prepared expandable graphite in a muffle furnace at 950°C for 10 seconds at high temperature to obtain expanded graphite with an expansion volume of 400mL / g.

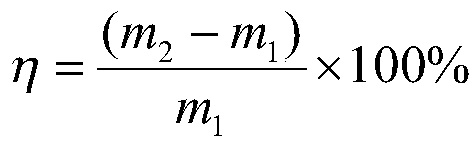

[0016] The expansion volume test method of expanded graphite is determined by the method in "Expandable Graphite (GB / T10698-1989)": Weigh an appropriate amount of expandable graphite sample, accurate to 0.001g, and place it at a high temperature of 900-1000°C Put it into a quartz beaker that has been ignited in the furnace for 5 minutes, and immediately put it into a hig...

Embodiment 2

[0024] Mix 3g of natural flake graphite with a particle size of 32 mesh and a carbon content of 99.9% with 1.26g of potassium permanganate, then add 21.6mL of perchloric acid with a mass fraction of 70-72%, and keep stirring. After the reaction, soak in 50mL saturated dipotassium hydrogen phosphate solution at room temperature for 60min to carry out the second intercalation reaction; Dry for 24 hours to obtain sulfur-free expandable graphite; expand the prepared expandable graphite in a muffle furnace at 950°C for 10 seconds at high temperature to obtain expanded graphite with an expansion volume of 410mL / g.

[0025] Get 1g of the prepared expanded graphite to adsorb heavy oil, and the adsorption ratio is 95g / g.

Embodiment 3

[0027] Mix 3g of natural flake graphite with a particle size of 32 mesh and a carbon content of 99.9% with 1.2g of potassium permanganate, and then add 21mL of perchloric acid with a mass fraction of 70-72%, stirring continuously, at 22°C React for 65 minutes. After the reaction, soak in 50 mL of saturated dipotassium hydrogen phosphate solution at room temperature for 60 minutes to carry out the second intercalation reaction; Dry for 24 hours to obtain sulfur-free expandable graphite; expand the prepared expandable graphite in a muffle furnace at 950°C for 10 seconds at high temperature to obtain expanded graphite with an expansion volume of 430mL / g.

[0028] 1 g of the prepared expanded graphite was used to adsorb crude oil, and the oil absorption ratio was 114 g / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com