Conductive adhesive for lithium ion batteries, preparation method thereof, electrode plate of lithium ion battery, preparation method thereof and lithium ion battery

A lithium-ion battery, conductive binder technology, applied in non-aqueous electrolyte battery electrodes, battery electrodes, secondary batteries, etc. resistance increase and other problems, to achieve the effects of strong mechanical properties, low cost, and increased content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

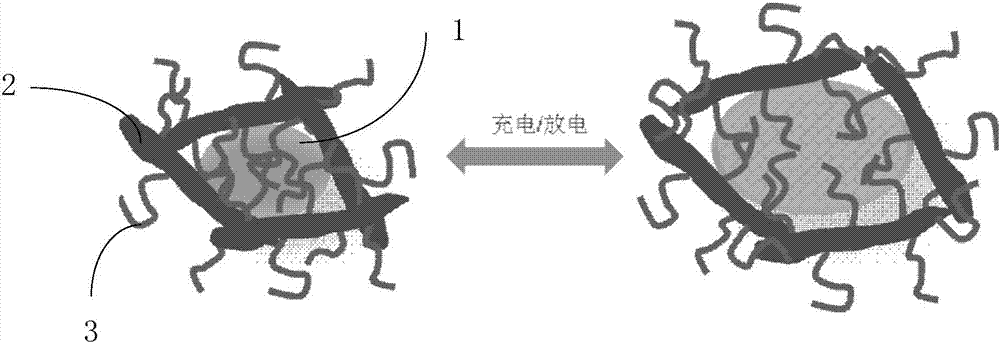

[0042] Correspondingly, an embodiment of the present invention provides a method for preparing the above-mentioned conductive adhesive for lithium ion batteries, comprising the following steps:

[0043] Graphene is obtained after oxidation treatment to obtain graphene oxide; the first binder is taken, and the first binder is grafted to the surface of the graphene oxide through a condensation reaction; or the monomer of the first binder is taken , the monomer of the first binder is polymerized and grafted to the surface of the graphene oxide by atom transfer radical polymerization to obtain the graphene grafted and modified by the first binder, that is, to obtain the lithium ion Conductive adhesive for batteries; the first adhesive includes polyvinyl alcohol, carboxymethyl cellulose, polyethylene glycol, polylactic acid, polymethyl methacrylate, polystyrene, polyvinylidene fluoride, hexa At least one of fluoropropylene polymer, styrene-butadiene rubber, sodium alginate, starch,...

Embodiment 1

[0060] A preparation method for a lithium-ion battery conductive binder, comprising the following steps:

[0061] (1) Weigh 10g of graphene, mix it with 100g of concentrated nitric acid (65wt%) aqueous solution, heat to 95°C, stir for 4h, wash and dry to obtain graphene oxide sample G;

[0062](2) Add 10g graphene oxide sample G to 100ml dimethyl sulfoxide (DMSO), add 2g thionyl chloride, stir and react at room temperature for 2h, after the reaction is completed, wash with DMSO, redisperse in DMSO, and add 2g of PVA, stirred at 120°C for 2h, washed with water and dried to obtain PVA graft-modified graphene G-PVA;

[0063] (3) Disperse G-PVA in water, first feed nitrogen to remove oxygen, then add 2g acrylic acid, 0.1g K 2 S 2 o 8 with 0.03g NaHSO 3 , heated to 55 ° C, reacted for 2-4h, the reaction was completed, dried after washing to obtain polyvinyl alcohol-polyacrylic acid (PVA-PAA) grafted graphene G-PVA-b-PAA;

[0064] (4) Disperse G-PVA-b-PAA in water, add LiOH aqu...

Embodiment 2

[0069] A preparation method for a lithium-ion battery conductive binder, comprising the following steps:

[0070] (1) Weigh 10 g of graphene, mix it with 100 g of concentrated nitric acid (65 wt%) aqueous solution, heat to 95° C., stir for 4 hours, wash and dry to obtain graphene oxide sample G.

[0071] (2) Disperse 10g of graphene oxide in 100ml of tetrahydrofuran (THF) under stirring, add 1g of diborane, stir at room temperature for 12h, and reduce the carboxyl, acid anhydride, carbonyl, etc. on the surface of graphene oxide to alcoholic hydroxyl groups; then use THF After washing and drying, redisperse in the mixed solution of 2g pyridine and 100mL dry ether, add 2g 2-bromoisobutyryl bromide (BiBB), stir slowly at 0°C for 2h, and then stir the reaction at room temperature for 10h. Drying after washing with absolute ethanol to obtain hydroxybrominated graphene oxide G-Br;

[0072] (3) Add 100mL of methanol, 3g of vinylidene fluoride, 0.02g of cuprous bromide (CuBr), and 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com