Carbon nano-tube fiber cement-based material and preparation thereof

A technology of carbon nanotube fibers and cement-based materials, which is applied in the field of toughening cement-based materials and their preparation, and can solve the problems of low toughness, low bending resistance and low fracture strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0011] Embodiment 1: In this embodiment, the carbon nanotube fiber cement-based material is made of fiber dispersant, organic solvent, carbon fiber, carbon nanotube, deionized water, superplasticizer, polymer emulsion, mineral admixture and cement wherein the mass ratio of carbon nanotubes to fiber dispersant is 1:0.5-15, the mass ratio of carbon fibers to fiber dispersant is 1:0.1-10, and the mass ratio of carbon nanotubes to carbon fibers is 1:0.5-15 , the mass ratio of deionized water to cement is 0.30~0.80:1, the mass ratio of superplasticizer to cement is 0.005~0.015:1, the mass ratio of polymer emulsion to cement is 0.05~0.20:1, mineral blending The mass ratio of material to cement is 0.05-0.15:1.

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the fiber dispersant is one of cationic dispersant, anionic dispersant, and nonionic dispersant, or it is a combination of nonionic dispersant and cationic dispersant. A combination of agent and anionic dispersant; cationic dispersant is cetyltrimethylammonium bromide; nonionic dispersant is methyl cellulose, carboxyethyl cellulose, nonylphenol polyoxygen One or a combination of vinyl ether and gum arabic; the anionic type is sodium dodecylbenzenesulfonate and sodium polyacrylate; the organic solvent is absolute ethanol, acetone, tetrahydrofuran (THF), dimethylformamide (DMF), chloroform, ethyl acetate or decalin. Others are the same as in the first embodiment.

specific Embodiment approach 3

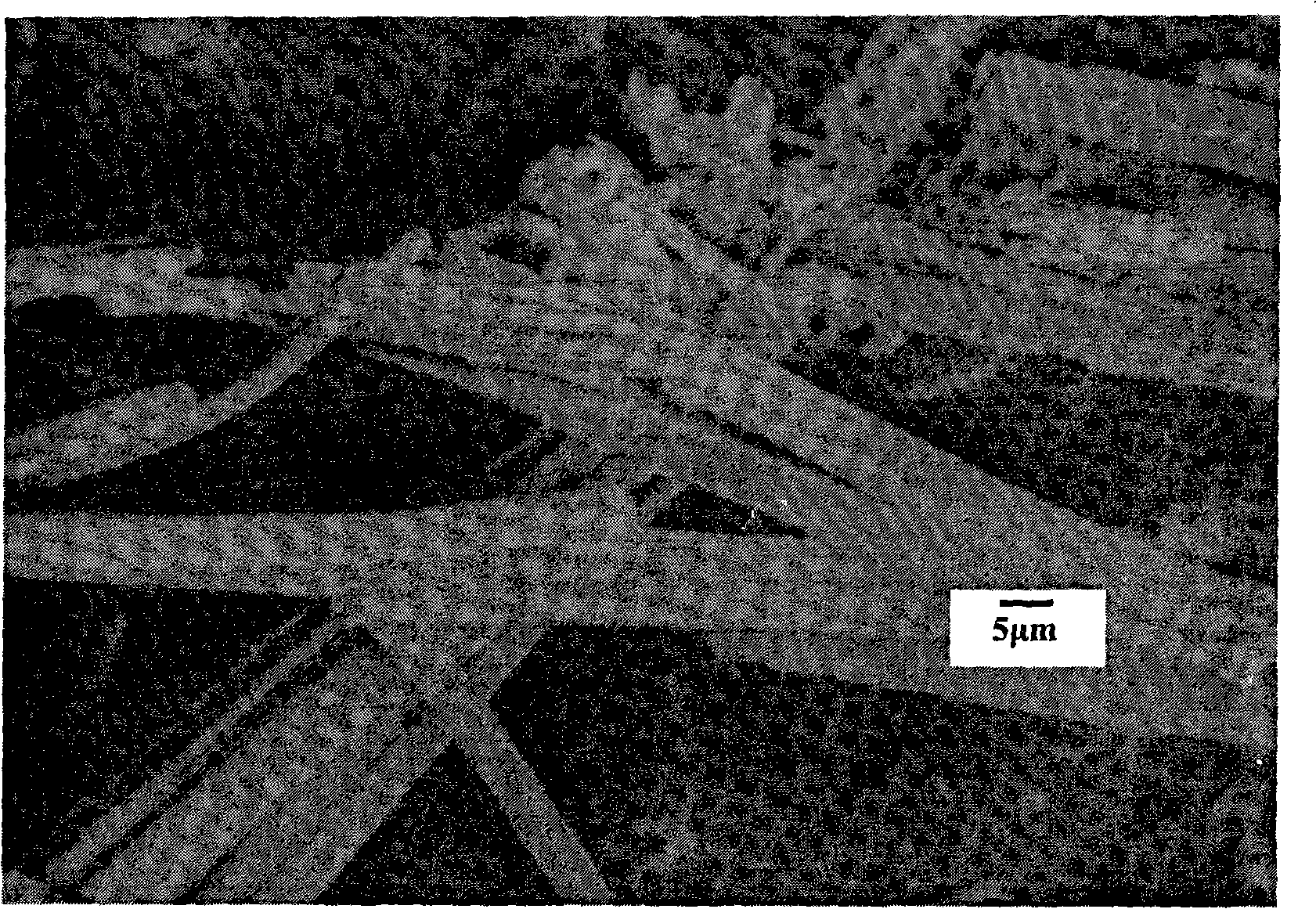

[0013] Embodiment 3: This embodiment is different from Embodiment 1 in that the carbon nanotubes are carbon nanotubes with an average diameter of 1 nm to 200 nm and a length of 0.1 μm to 20 μm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com