Flexible polymer-based graphene foam material and preparation method thereof

A graphene foam and flexible polymer technology, which is applied in the field of flexible polymer-based graphene foam materials and their preparation, can solve the problems of incompressible springback, fragile mechanical properties, and long time required to achieve high surface hydrophobicity, The effect of short preparation time and simple and easy-to-operate preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

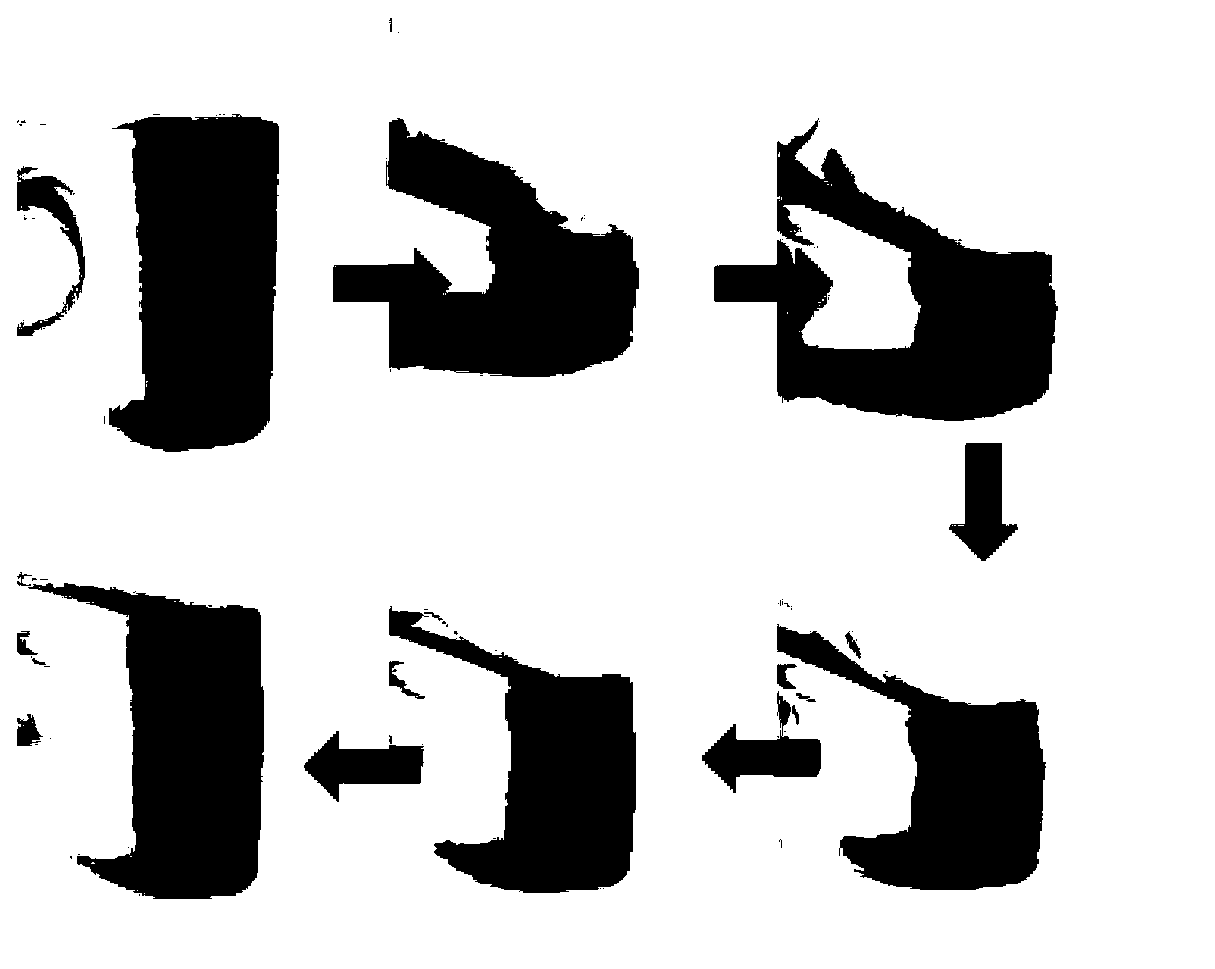

[0028] The preparation method of flexible polymer-based graphene foam material of the present invention mainly comprises following two steps:

[0029] (1) The polymer foam is soaked in the graphene oxide solution containing hydrazine hydrate by vacuum degassing method, and the volume of the polymer foam is the same as that of the graphene oxide solution;

[0030] (2) The above mixed solution was reacted at 60-90° C. for 5-15 hours, and then dehydrated, washed and dried to obtain a flexible polymer-based graphene foam composite material.

Embodiment 1

[0033] The preparation method of the polymer-based graphene foam material in the present embodiment is as follows:

[0034] (1) Disperse 2.5mg of graphene oxide in 50ml of aqueous solution, then add 0.05ml of hydrazine hydrate, stir to dissolve the graphene oxide, and soak the polymer foam in the prepared mixed solution by extrusion and vacuum degassing , the volume of the foam is roughly the same as the volume of the solution;

[0035] (2) The above mixed solution was reacted at 60°C for 15 hours, and then dehydrated, washed, and dried to obtain a flexible polymer-based graphene foam composite material.

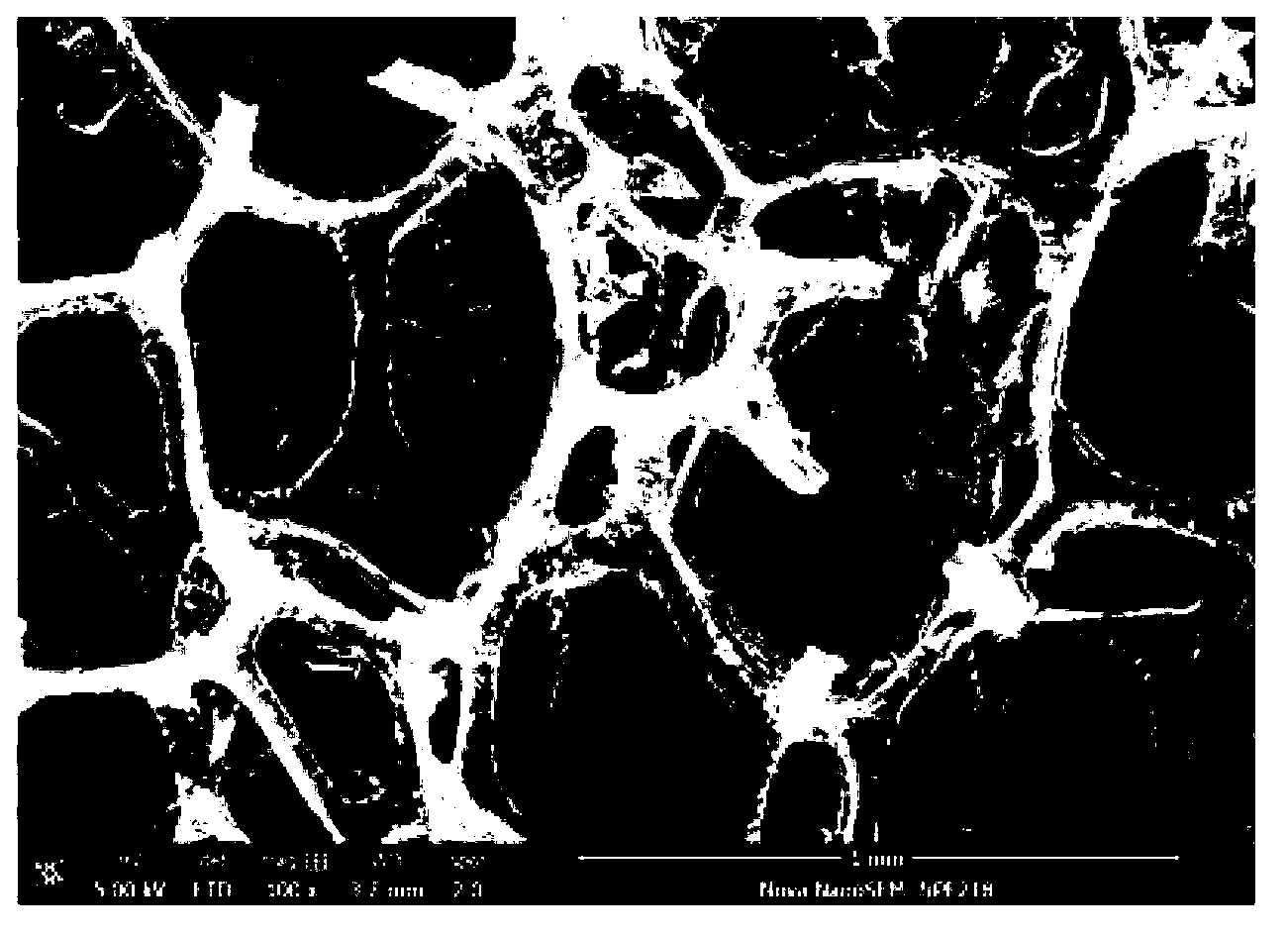

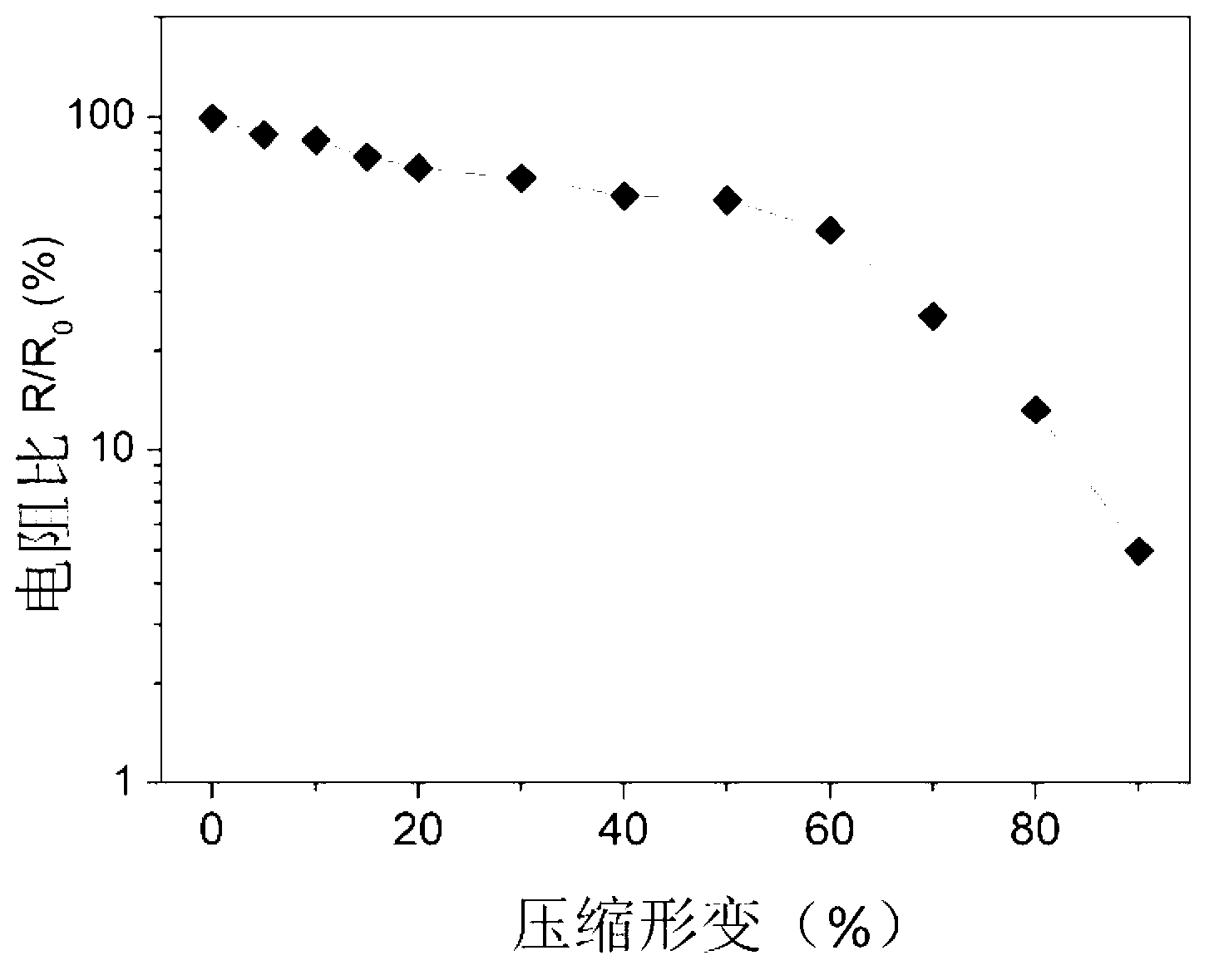

[0036] In this embodiment, the weight percent content of graphene in the polymer-based graphene foam material is 0.1%, the volume conductivity is 0.001S / m, the surface water contact angle is 121.2°, and the compression deformation can reach 90%.

Embodiment 2

[0038] The preparation method of the polymer-based graphene foam material in the present embodiment is as follows:

[0039] (1) Disperse 12.5mg of graphene oxide in 50ml of aqueous solution, then add 0.25ml of hydrazine hydrate, stir to dissolve, and soak the polymer foam in the prepared mixed solution by extrusion and vacuum degassing. The volume is roughly the same as the volume of the solution;

[0040] (2) The above mixed solution was reacted at 70°C for 12 hours, and then dehydrated, washed, and dried to obtain a flexible polymer-based graphene foam composite material.

[0041] In this embodiment, the weight percent content of graphene in the polymer-based graphene foam material is 0.5%, the volume conductivity is 0.005S / m, the surface water contact angle is 123.4°, and the compression deformation can reach 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com