Method for carrying out hole sealing treatment on anodic alumina, component of overhead contact system of electric railway, by using silane coupling agent

A silane coupling agent, anodized aluminum technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problem of high energy consumption of boiling water sealing, troublesome maintenance of bath liquid, and harsh process conditions for boiling water sealing And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

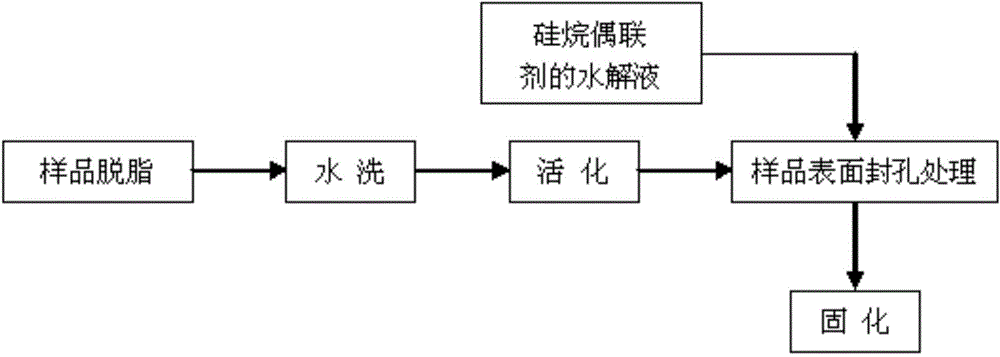

Method used

Image

Examples

example 1

[0018] First, the anodized aluminum sample was ultrasonically treated in acetone solution for 10 minutes, then rinsed with distilled water for 3 times, then placed in hydrogen peroxide activation solution (the mass fraction of hydrogen peroxide was 5%), soaked at 65°C for 5 minutes, and the sample The surface is rich in a large number of hydroxyl groups; the silane coupling agent (γ-glycidyl etheroxypropyltrimethoxysilane, A-187), methanol and water are mixed in a fixed ratio of 1:8:1 by mass, and then a small amount of Acetic acid adjusts the pH value of the silane coupling agent alcohol aqueous solution to 4, and the hydrolysis time is controlled to 3 hours; soak the activated sample in the silane coupling agent A-187 alcohol aqueous solution for 10 minutes, and then take it out. Curing at room temperature to obtain a sealed sample. The neutral salt spray test of this sample can reach 800 hours without obvious rust spots, and the contact angle of water on its surface is 105°...

example 2

[0020] Firstly, the anodized aluminum sample was ultrasonically treated in acetone solution for 15 minutes, then rinsed with distilled water for 3 times, then put it into hydrogen peroxide activation solution (the mass fraction of hydrogen peroxide was 5%), soaked at 65°C for 8 minutes, and made the sample The surface is rich in a large number of hydroxyl groups; the silane coupling agent (methyltrimethoxysilane, Z-6070), methanol and water are miscible at a fixed ratio of 1:6:1 by mass, and then a small amount of acetic acid is added to adjust the silane coupling agent The pH value of the alcohol aqueous solution reaches 4, and the hydrolysis time is controlled at 5 hours; soak the activated sample in the alcohol aqueous solution of silane coupling agent Z-6070 for 50 minutes, then take it out, and solidify at a constant temperature of 60°C to obtain Sealed samples. The neutral salt spray test of this sample can reach 950 hours without obvious rust spots, and the surface has ...

example 3

[0022] First, the anodized aluminum sample was ultrasonically treated in acetone solution for 15 minutes, then rinsed with distilled water for 5 times, then put it into hydrogen peroxide activation solution (the mass fraction of hydrogen peroxide was 5%), soaked at 65°C for 10 minutes, and made the sample The surface is rich in a large number of hydroxyl groups; the silane coupling agent (methyltrimethoxysilane, Z-6070), methanol and water are miscible at a fixed ratio of 1:6:1 by mass, and then a small amount of acetic acid is added to adjust the silane coupling agent The pH value of the alcohol aqueous solution reaches 4, and the hydrolysis time is controlled at 8 hours; soak the activated sample in the alcohol aqueous solution of silane coupling agent Z-6070 for 80 minutes, then take it out, and solidify at a constant temperature of 60°C to obtain Sealed samples. The neutral salt spray test of this sample can reach 1000 hours without obvious rust spots, and the surface has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com