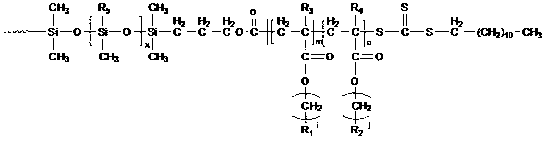

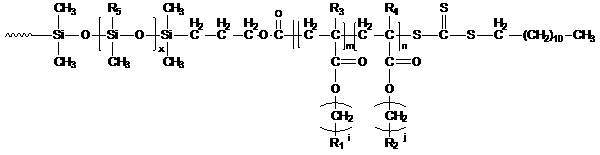

POSS (polyhedral oligomeric silsesquioxane) contained polyacrylate-polysiloxane block copolymer and preparation method thereof

A polysiloxane block and polyacrylate technology, which is used in biocide-containing paints, coatings, antifouling/underwater coatings, etc. Limited range and other problems, to achieve the effect of improving surface hydrophobicity, improving surface properties, and improving softness and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (a) Weigh 30g of double-ended hydrogen-terminated polydimethylsiloxane (molecular weight: 1000), 28.6g of isopropanol, and 1.74g of propenyl alcohol, add them into a 250mL three-necked flask, add 68μL of platinum catalyst, and stir magnetically , react at 20°C for 1h, then raise the temperature to 6°C for 1.5h. Remove the solvent from the obtained liquid on a rotary evaporator, and dry it in vacuum to obtain a hydroxyl-terminated polydimethylsiloxane with a molecular weight of 2000;

[0028] (b) Add 10 g of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 1000, 1.1 g of the catalyst dicyclohexylcarbodiimide (DCC), and 100 mL of anhydrous dichloromethane into a 250 mL single-necked flask, and then add 4.55 g trithiocarbonate (DDMAT). After the addition, it was stirred at room temperature for 72h. Add n-hexane for dilution, filter out insoluble matter, use a rotary evaporator to remove the solvent, centrifuge at a speed of 5000r / min for 5min, take the...

Embodiment 2

[0031](a) Weigh 30g of double-ended hydrogen-terminated polytrifluoropropylmethylsiloxane (molecular weight: 2000), 18.6g of isopropanol, and 0.87g of propenyl alcohol, add them to a 250mL three-necked flask, and then add 34μL of platinum catalyst , magnetically stirred, reacted at 30°C for 0.5h, then raised the temperature to 100°C for 0.5h. Remove the solvent from the obtained liquid on a rotary evaporator, and dry it in vacuum to obtain a hydroxyl-terminated polytrifluoropropylsiloxane with a molecular weight of 2000;

[0032] (b) Add 10g of hydroxyl-terminated polytrifluoropropylmethylsiloxane with a molecular weight of 2000, 2.0g of the catalyst dicyclohexylcarbodiimide (DCC), and 150mL of anhydrous dichloromethane into a 250mL one-necked flask , and then added 4.55 g trithiocarbonate (DDMAT). After the addition, it was stirred at room temperature for 72h. Add n-hexane for dilution, filter out insoluble matter, use a rotary evaporator to remove the solvent, centrifuge a...

Embodiment 3

[0035] (a) Weigh 30g of single-end hydrogen-terminated polydimethylsiloxane (molecular weight: 5000), 30g of isopropanol, and 0.70g of propenyl alcohol, and add them into a 250mL three-necked flask, then add 21μL of platinum catalyst, stir magnetically, React at 25°C for 1h, then raise the temperature to 65°C for 1h. Remove the solvent from the obtained liquid on a rotary evaporator, and dry it in vacuum to obtain a hydroxyl-terminated polydimethylsiloxane with a molecular weight of 5000;

[0036] (b) Add 10g of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 5000, 1.8g of catalyst dicyclohexylcarbodiimide (DCC), and 120mL of anhydrous dichloromethane into a 250mL single-necked flask, and then add 4.55 g trithiocarbonate (DDMAT). After the addition, it was stirred at room temperature for 72h. Add n-hexane for dilution, filter out insoluble matter, use a rotary evaporator to remove the solvent, centrifuge at a speed of 5000r / min for 5min, take the upper la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com