Preparation method for polysiloxane emulsion modified waterborne polyurethane emulsion

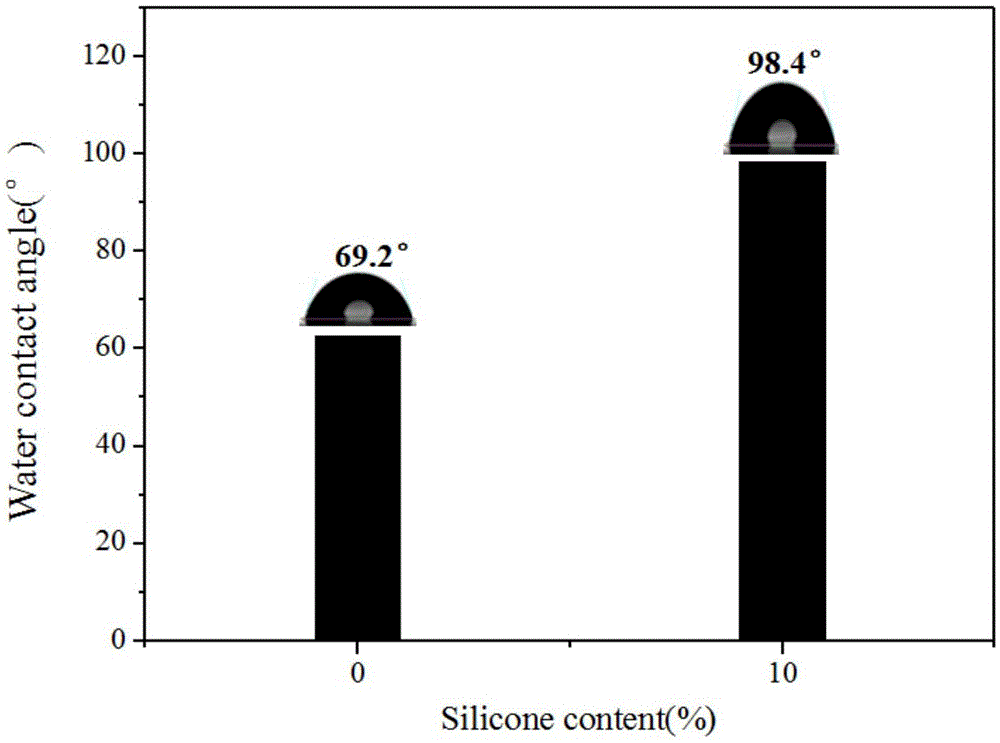

A technology of polysiloxane emulsion and water-based polyurethane, which is applied in the field of preparation of water-based polyurethane hybrid emulsion, can solve the problem that the emulsion colloidal stability and the microstructure of the film are not easy to control, and the improvement of water resistance and surface hydrophobicity is not obvious or even decline, the mechanical properties of the system do not improve significantly or even decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

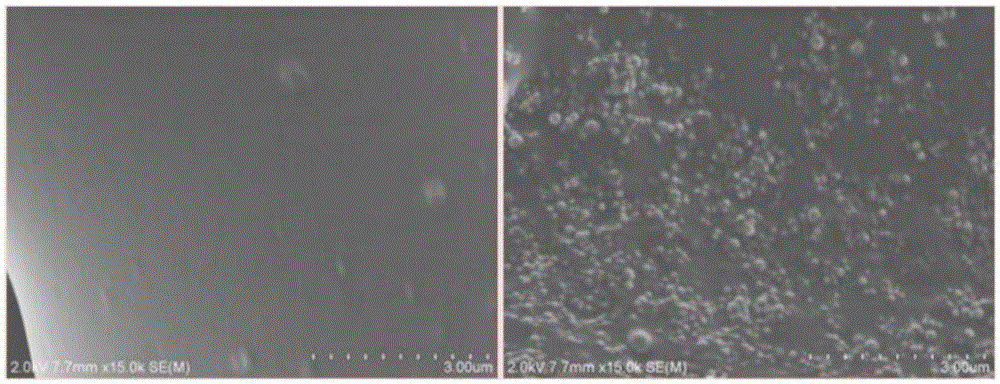

[0020] Polysiloxane microsphere emulsion: Weigh 0.2g sodium dodecylsulfonate, 0.1g sodium bicarbonate and 0.1g sodium dihydrogen phosphate in 40.0g deionized water and mix uniformly to form a water phase, and add into a 250mL four-neck flask. In addition, weigh 9.0g vinyltrimethoxysilane monomer, 0.5g hexadecane and 0.2g azobisisobutyronitrile according to the proportion, mix and disperse evenly to form an oil phase, and add the oil phase components dropwise to the water phase group Stir and emulsify while adding dropwise, stir for 0.5h for coarse emulsification, then finely emulsify for 10min, after fine emulsification, polymerize at 70°C for 5h to obtain a polyorganosiloxane emulsion

Embodiment 2

[0022] Preparation of water-based polyurethane film: Add 17.4g of isophorone diisocyanate (IPDI) into a 250mL four-necked flask equipped with a stirrer, thermometer and reflux condenser, and add 57.1g of polycarbonate dropwise with a dropping funnel while stirring at room temperature Ester polyol (PCD2000) and 0.05g catalyst dibutyltin dilaurate (DBTDL), the dropping rate is controlled within 1.5h, after the addition is completed, react at 45±5°C for 1-2h; then raise the temperature to 60°C, add 3.75g Dimethylolpropionic acid (DMPA), reacted for 3-4h, measured the degree of reaction by the toluene-di-n-butylamine back titration method until the NCO group content reached the theoretical value; then added 2.83g of triethylamine to the resin , react for 0.5-1h; add 198.3g of deionized water dropwise to the system for emulsification; and finally prepare a water-based polyurethane film.

Embodiment 3

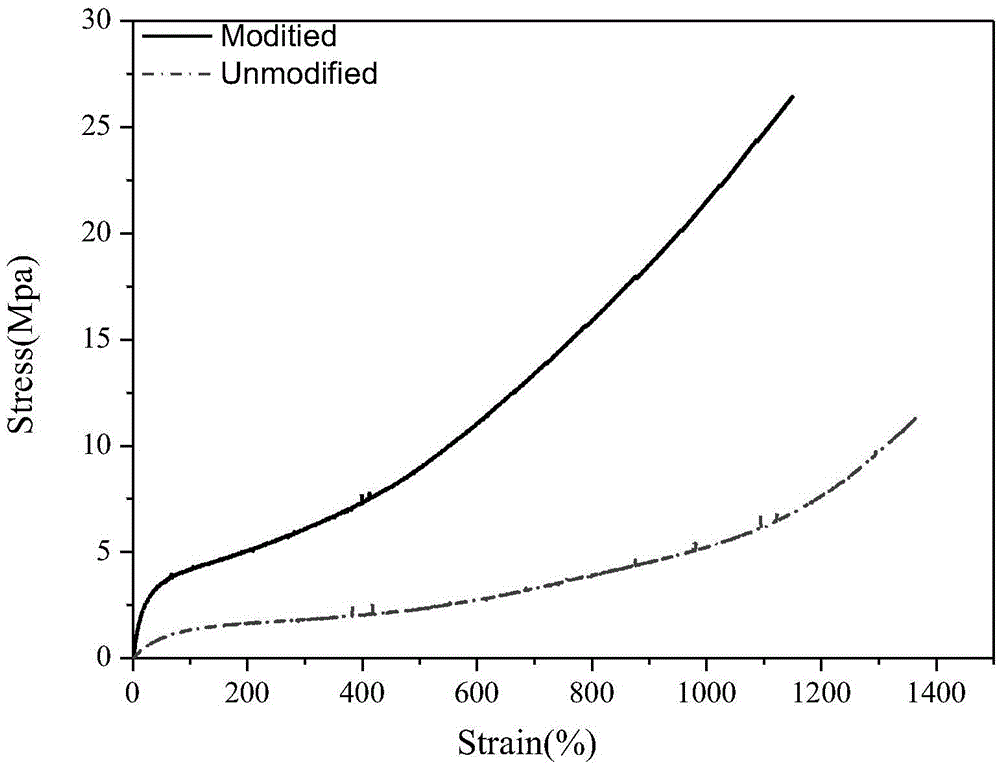

[0024] Preparation of silicone-modified water-based polyurethane film: Add 17.4g of isophorone diisocyanate (IPDI) to a 250mL four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, and add it dropwise with a dropping funnel while stirring at room temperature 51.3g of polycarbonate polyol (PCD2000) and 0.05g of catalyst dibutyltin dilaurate (DBTDL), the dropping speed is controlled within 1.5h, and after the dropping is completed, react at 45±5°C for 1-2h; add 6.85g Organosilicon compound (PDMS), react for 0.5-1h; then heat up to 60°C, add 3.75g dimethylolpropionic acid (DMPA), react for 3-4h, measure the reaction degree by toluene-di-n-butylamine back titration method, Until the determined NCO group content reaches the theoretical value; then add 2.83g of triethylamine to the resin and react for 0.5-1h; add 198.3g of deionized water dropwise to the system for emulsification; finally prepare a waterborne polyurethane film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com