Preparation method of alkali-resistant silica gel chromatographic column filling material

A silica gel chromatography and alkali-resistant technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low coverage density of organic layer on the surface of silica gel chromatography packing, collapse of silica packing matrix, reduction of resolution and column efficiency, etc. To achieve the effect of weak residual silanol effect, small molecular loss and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

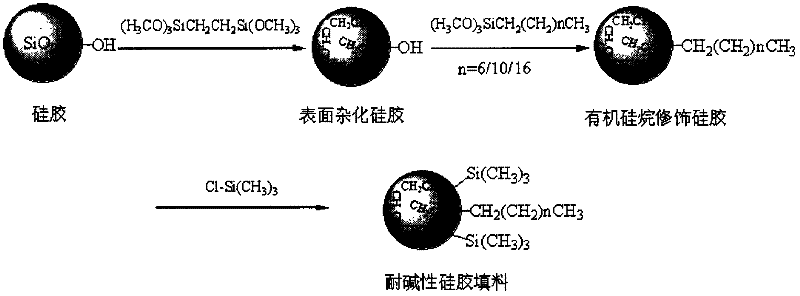

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the preparation of alkali-resistant carbon-octave silica gel chromatographic packing

[0026] Include the following steps A and B in turn:

[0027] A. Preparation of surface organohybrid silica gel

[0028] Add 5.0 g of activated fully porous spherical silica gel into the reaction vessel, add 50 ml of toluene, stir evenly, add 0.5 g of ethylene bridged hexaethoxysilane, protect it with high-purity nitrogen, and stir and reflux for 12 hours. Cool after the reaction, filter with suction, wash with 200ml of toluene, 200ml of ethanol, 200ml of ethanol-water (v / v, 1:1), 200ml of water, 200ml of methanol in turn, and dry in vacuum at 70°C for 12h to obtain the surface ethylidene complex. Silicone.

[0029] B. Preparation of alkali-resistant silica gel chromatography packing

[0030] Add 5.0g surface ethylene hybrid silica gel into the reaction vessel, add 50ml toluene, stir evenly, add 2.5g octadecyldimethylchlorosilane, protect with high-purity nitrogen, sti...

Embodiment 2

[0031] Embodiment 2: Preparation of alkali-resistant C12 silica gel chromatographic packing

[0032] Include the following steps A and B in turn:

[0033] A. Preparation of surface organohybrid silica gel

[0034] Add 5.0 g of activated fully porous spherical silica gel into the reaction vessel, add 50 ml of toluene, stir evenly, add 0.25 g of methyltriethoxysilane, protect with argon, and stir and reflux for 12 hours. After the reaction is completed, cool, filter with suction, wash with 200ml of toluene, 200ml of ethanol, 200ml of ethanol-water (v / v, 1:1), 200ml of water, and 200ml of methanol, and dry in vacuum at 70°C for 12h to obtain a surface methyl hybrid. Silica gel.

[0035] B. Preparation of alkali-resistant silica gel chromatography packing

[0036] Add 5.0g of surface methyl hybrid silica gel into the reaction vessel, add 50ml of toluene, stir evenly, add 5.0g of dodecyltrimethoxysilane, protect with high-purity nitrogen, stir and reflux for 24h. After the reac...

Embodiment 3

[0037] Embodiment 3: the preparation of alkali-resistant carbon eight silica gel chromatographic packing

[0038] Include the following steps A and B in turn:

[0039] A. Preparation of surface organohybrid silica gel

[0040]Add 5.0 g of activated fully porous spherical silica gel into the reaction vessel, add 50 ml of toluene, stir evenly, add 0.125 g of ethyltrimethoxysilane, protect with high-purity nitrogen, and stir to reflux for 12 hours. After the reaction is completed, cool, filter with suction, wash with 200ml of toluene, 200ml of ethanol, 200ml of ethanol-water (v / v, 1:1), 200ml of water, and 200ml of methanol, and dry in vacuum at 70°C for 12h to obtain a surface ethyl hybrid. Silica gel.

[0041] B. Preparation of alkali-resistant silica gel chromatography packing

[0042] Add 5.0g surface ethyl hybrid silica gel into the reaction vessel, add 50ml toluene, stir evenly, add 3.0g octyldimethylmethoxysilane, protect with high-purity nitrogen, stir and reflux for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com