Melamine resin microcapsule lubricating oil and lubricating oil coating material, and preparation methods thereof

A technology of melamine resin and coating materials, which is applied in the direction of coatings and lubricating compositions, can solve the problems that the lubricating performance is not as good as that of lubricating oil, and does not involve the preparation process of solid lubricating coatings, so as to achieve improved physical properties and excellent stability and friction and wear properties, and the effect of maintaining lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of melamine resin prepolymer: Add 1 kg of melamine, 5 L of formaldehyde and glyoxal compound solution, and 10 L of deionized water into a three-necked flask, stir and mix; adjust the pH value to 8-9 with sodium hydroxide solution, and React at ℃ for 30 minutes; after the melamine is completely dissolved, a transparent melamine resin prepolymer is obtained, in which the molar percentage of the compound solution of formaldehyde and glyoxal is 8:1.

Embodiment 2

[0042] (1) Pretreatment of lubricating oil: Mix 0.025 kg of nickel-copper-zinc ferrite with 4.975 kg of 100# engine oil containing nano-silver sulfide, stir for 0.5 h at a speed of 1000 r / min with a powerful motor, and then ultrasonically Disperse evenly and reserve;

[0043] (2) Add 1 kg of polyvinyl alcohol and 1 kg of sodium dodecylbenzene sulfonate into a beaker, add deionized water, and after dissolving, add to the pretreated lubricating oil in step 1, stir and emulsify for 10 minutes to obtain emulsified Lubricating oil dispersion system;

[0044] (3) Divide the emulsified lubricating oil dispersion system into three times, with an interval of 1 minute between each time, slowly pour it into the melamine resin prepolymer of the same volume as in Example 1, stir at a speed of 500 r / min, and emulsify for 30 minutes;

[0045](4) Adjust the pH value of the product in step 3 to 2 with hydrochloric acid, and heat and react in a water bath at 65°C for 3 hours;

[0046] (5) Suc...

Embodiment 3

[0048] Disperse 20kg of melamine resin microcapsule lubricating oil and 68kg of epoxy silicone in 7kg of OP-10 in Example 2. After stirring evenly, add 6kg of talcum powder, 4kg of aluminum oxide and 0.5kg of antimony trioxide in sequence, and then After ultrasonic dispersion and ball mill dispersion, filter to obtain lubricating oil coating material.

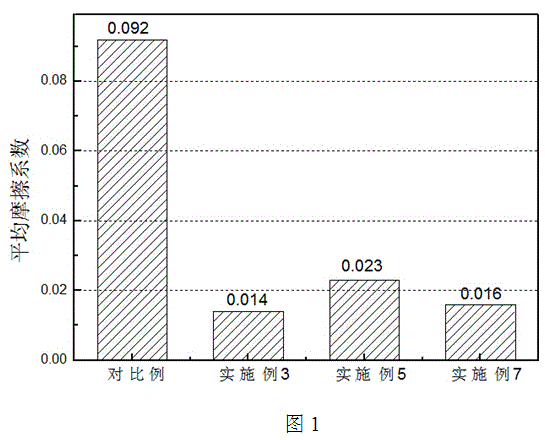

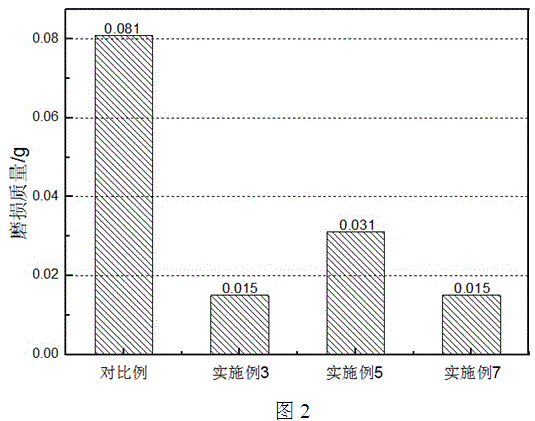

[0049] After the obtained lubricating oil coating material was sprayed on the steel sheet, under the conditions of 240 N load, 180 rpm rotation speed, and 600s storage time, a small pin-on-disc friction and wear test was carried out on the steel sheet sprayed with the lubricating oil coating, and the measured The average friction coefficient and wear results are 0.014 and 0.015g, respectively, as figure 1 and 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com