Water-based 2D/0D nanometer composite material lubricant

A nano-composite material, lubricant technology, applied in water-based nano-lubrication. It can solve problems such as few performance studies, and achieve the effect of eliminating biological pollution and air pollution problems, high load resistance performance, and low friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a preparation method of a 2D / 0D nanocomposite water-soluble lubricant applied in the field of machinery manufacturing, especially a mobile mechanical device and a kinematic pair of an engine used in industrial production. This method flow includes:

[0032] (1), the invented 2D / 0D nano-lubricant is composed of 2D nano-sheets and 0D nanoparticles at a mass ratio of 1:0 to 1:1 (or 1:1 to 1:0) to form a composite nanomaterial and dissolve in Ionized water is obtained (excluding the case where one of the substances is 0). The 2D nanoflakes used in the present invention are mainly graphene (G), reduced graphene oxide (RGO), graphene oxide (GO) and graphite-carbon nitride (g-C 3 N 4 one or more of );

[0033] (2) 2D nanoflakes can be synthesized by liquid phase redox method (improved Hemer synthesis method) or solid phase heat treatment method. The prepared multilayer 2D planar layered material is further exfoliated into 2D nanosheets with a thickne...

example 1

[0066] 2D graphene oxide is prepared as follows:

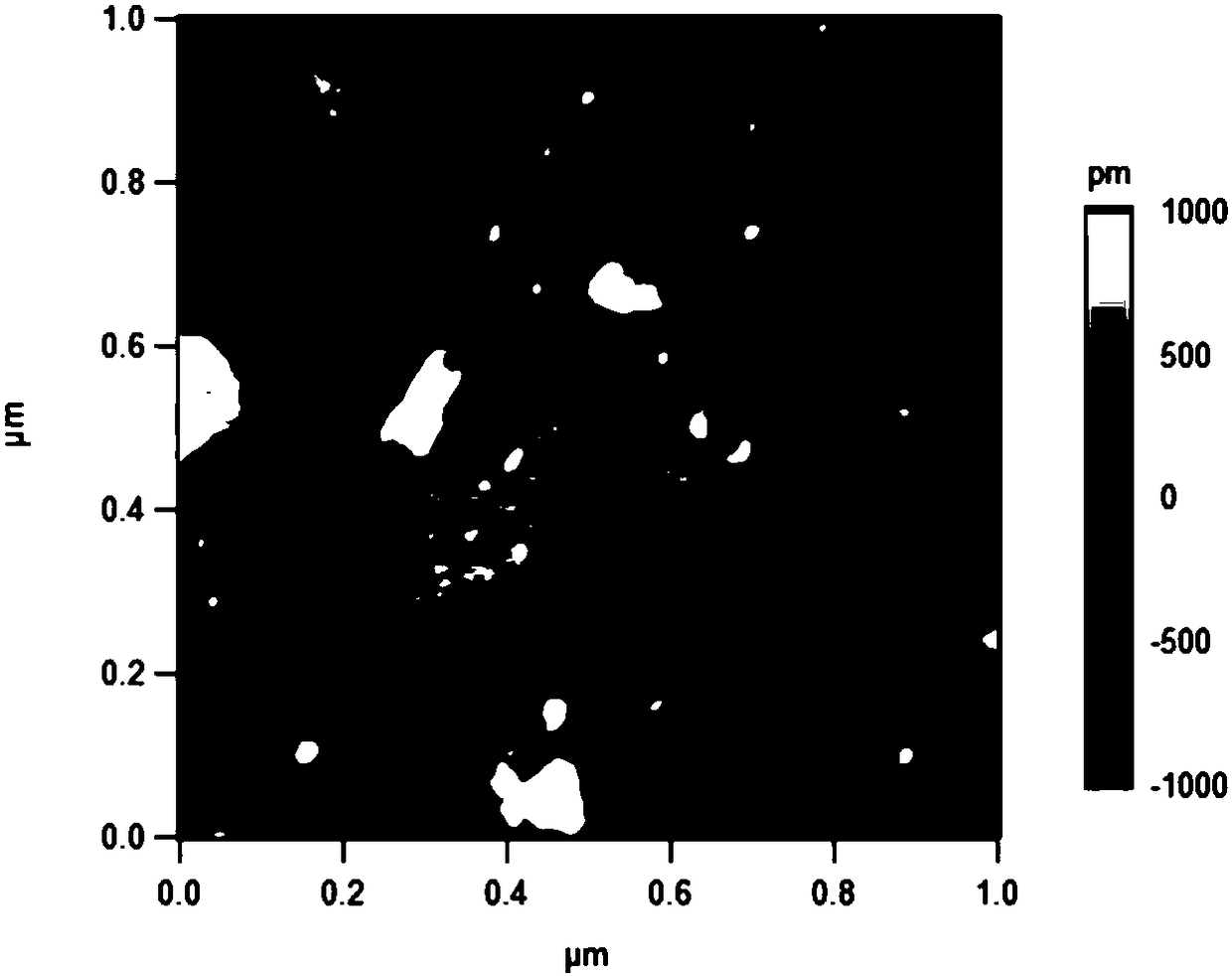

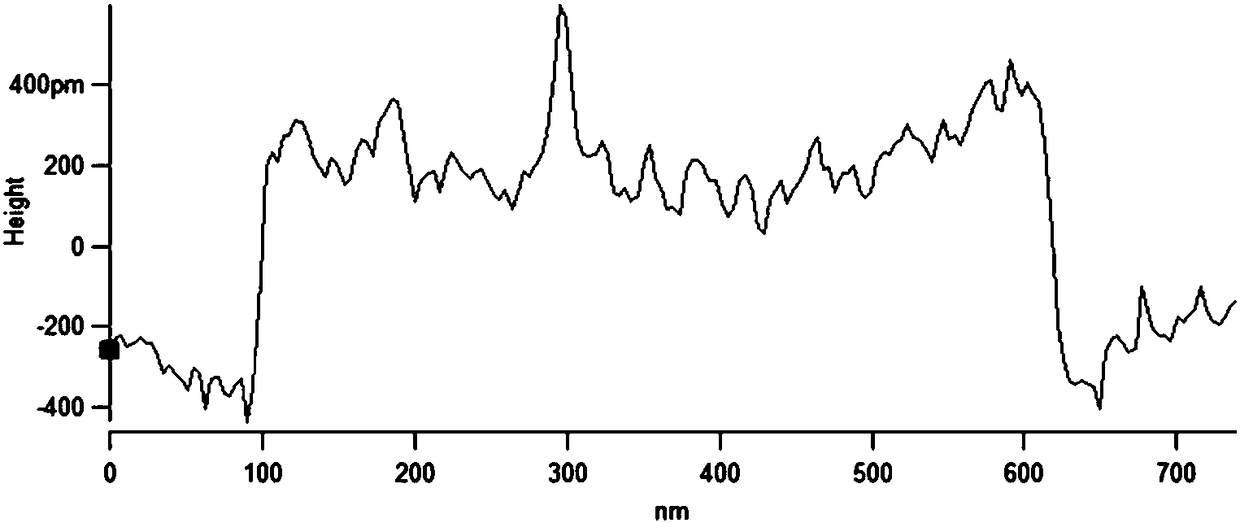

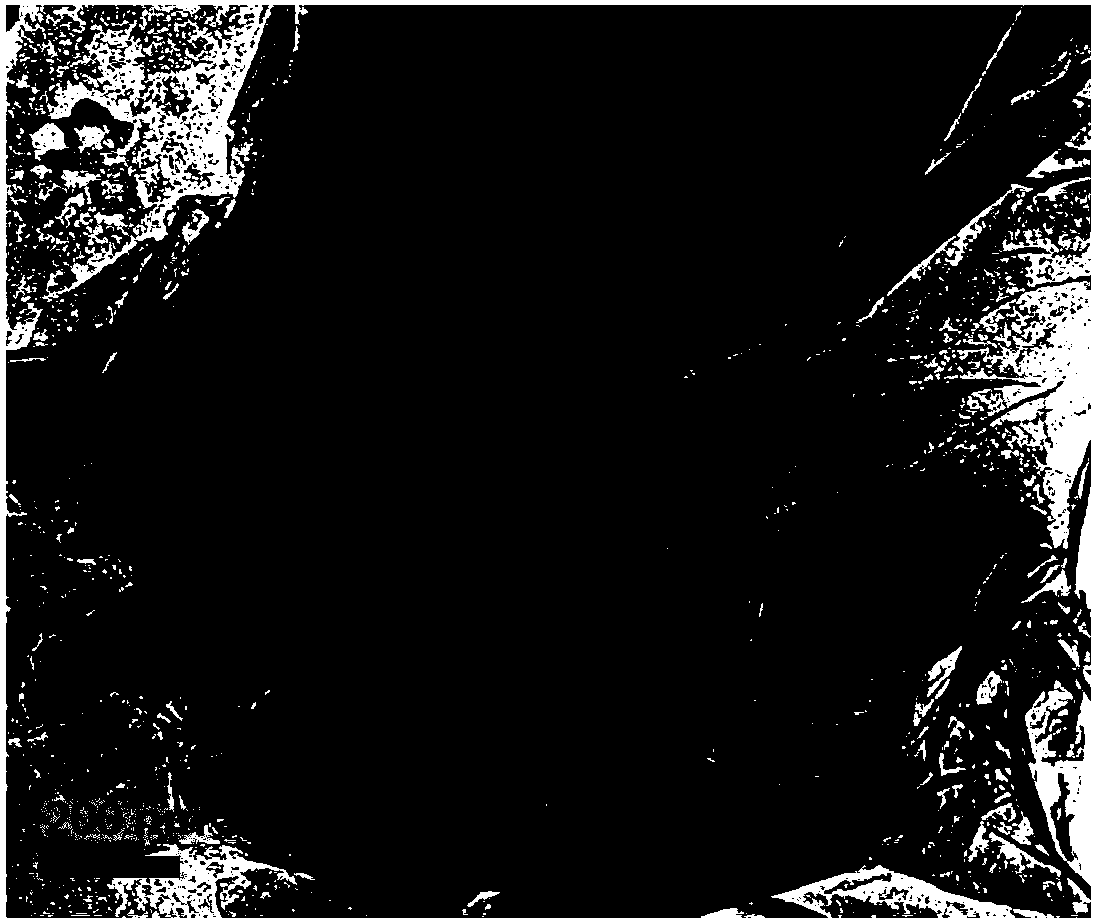

[0067] First, natural graphite powder was oxidized into graphite oxide in a highly acidic environment of sulfuric acid, nitric acid, and potassium chlorate using a modified Hemmer method. After the oxidation reaction, the graphite oxide solution was filtered and washed repeatedly with deionized water until the pH value of the filtrate was between 6 and 8. Followed by ultrasonic treatment for 30 minutes, 2D graphene oxide was obtained. figure 1 and figure 2 The AFM images of graphene oxide and its cross-sectional morphology are shown, respectively. according to figure 1 and figure 2 , the synthesized graphene oxide has a micron-scale lateral dimension and a thickness of about 0.5 nm, which facilitates the exfoliation of graphene oxide into 2D nanosheets. also, image 3 The TEM image of shows typical 2D graphene oxide nanoflakes with micrometer-scale lateral dimensions.

example 2

[0069] 2D / 0D-graphene oxide / nanoparticles (preferably TiO 2 or Al 2 o 3 ) The suitable concentration of the composite material in the deionized water is 0.1%-2% by weight. The composite of 2D graphene oxide nanoflakes and 0D inorganic nanoparticles is carried out as follows:

[0070] Synthetic or commercial inorganic nanoparticles were added to pH-controlled deionized water. Stirring was continued for 30 minutes to disperse into deionized water, followed by 30 minutes of sonication. Similarly, graphene oxide synthesized by the modified Hemer method was added to pH-controlled deionized water, and then the graphene oxide solution was slowly added to the nanoparticle suspension. Figure 4 A TEM image showing the composite 2D graphene oxide and TiO 2 nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com