Preparation method of lubricating material with nano-copper particles loaded on molybdenum disulfide nanosheets

A molybdenum disulfide and particle lubrication technology, applied in the directions of nanotechnology, nanotechnology, lubricating composition, etc., can solve the problems such as the preparation method of molybdenum disulfide nanosheet-loaded nano-copper particle lubricating material, which has not been reported, and achieves improved friction. The effect of wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

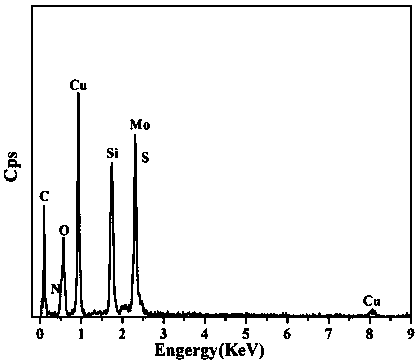

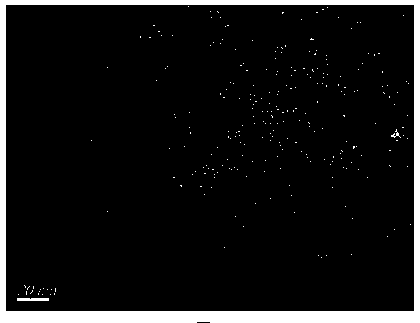

[0022] Step 1: Add 0.12g of sodium molybdate and 0.24g of thioacetamide into 80ml of deionized water and sonicate for 0.5h to prepare a uniform transparent liquid, then transfer the solution to a 100ml Teflon liner The reaction kettle was placed in a stainless steel reaction kettle, and then the reaction kettle was put into a blast oven, the reaction temperature was set to 240° C., and the reaction time was 24 hours. After cooling naturally to room temperature, the product in the reaction kettle was centrifuged and washed with absolute ethanol, and then the black product was dried in a vacuum oven to obtain molybdenum disulfide nanosheets.

[0023] Step 2: Disperse 0.04 g of molybdenum disulfide into 100 ml of Tris-HCL (pH=8.5) buffer solution and sonicate for 2 h to prepare a black liquid, then add 0.2 g of dopamine hydrochloride to the above solution and stir vigorously for 12 h, Centrifuge and wash the product several times with distilled water and ethanol, then disperse th...

Embodiment 2

[0029] Step 1: Add 0.12g of sodium molybdate and 0.24g of thioacetamide into 80ml of deionized water and sonicate for 0.5h to prepare a uniform transparent liquid, then transfer the solution to a 100ml Teflon liner The reaction kettle was placed in a stainless steel reaction kettle, and then the reaction kettle was put into a blast oven, the reaction temperature was set to 240° C., and the reaction time was 24 hours. After cooling naturally to room temperature, the product in the reaction kettle was centrifuged and washed with absolute ethanol, and then the black product was dried in a vacuum oven to obtain molybdenum disulfide nanosheets.

[0030] Step 2: Disperse 0.04 g of molybdenum disulfide into 100 ml of Tris-HCL (pH=8.5) buffer solution and sonicate for 2 h to prepare a black liquid, then add 0.2 g of dopamine hydrochloride to the above solution and stir vigorously for 12 h, Centrifuge and wash the product several times with distilled water and ethanol, then disperse th...

Embodiment 3

[0032] Step 1: Add 0.12 g of sodium molybdate and 0.24 g of thioacetamide into 80 ml of deionized water and sonicate for 0.5 h to prepare a homogeneous transparent liquid, then transfer the solution to a 100 ml Teflon liner The reaction kettle was placed in a stainless steel reaction kettle, and then the reaction kettle was put into a blast oven, the reaction temperature was set to 240° C., and the reaction time was 24 hours. After cooling naturally to room temperature, the product in the reaction kettle was centrifuged and washed with absolute ethanol, and then the black product was dried in a vacuum oven to obtain molybdenum disulfide nanosheets.

[0033] Step 2: Disperse 0.1 g of molybdenum disulfide into 100 ml of Tris-HCL (pH=8.5) buffer solution and sonicate for 2 h to prepare a black liquid, then add 0.2 g of dopamine hydrochloride to the above solution and stir vigorously for 12 h, Wash the product by centrifugation repeatedly with distilled water and ethanol, then dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com