Highly ductile, abrasive-wearable self-lubricant polyformaldehyde material and its preparation method

A polyoxymethylene material, self-lubricating technology, applied in the field of high wear-resistant self-lubricating polyoxymethylene material and its preparation, high toughness, to achieve the effect of less dosage, improved toughness and friction and wear performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

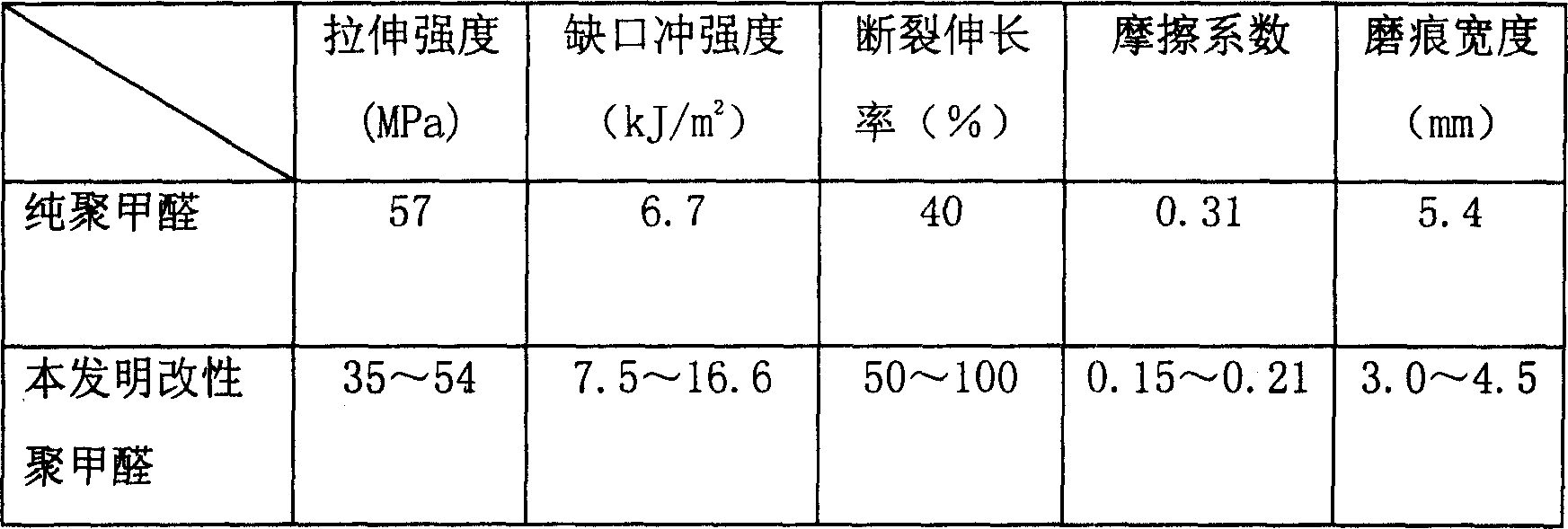

Embodiment 1

[0031] Dry 396g of copolymerized polyoxymethylene in an oven at 90°C for 4 hours, add 4g of polyethylene oxide with a molecular weight of 20,000, 1.2g each of antioxidant 264, aluminum hydroxide and melamine, and mix them evenly in a high-speed mixer. Melt blending and extrusion at a temperature of 170°C, the extrudate is rapidly cooled below the crystallization temperature of polyethylene oxide at a cooling rate of 60°C / min, and a structure with polyethylene oxide crystal layers intermingled inside polyoxymethylene spherulites is obtained polyoxymethylene material. Its notched impact strength is 7.5kJ / m 2 , The tensile strength is 54MPa, the elongation at break is 50%, the friction coefficient is 0.21, and the wear scar width is 4.5mm.

Embodiment 2

[0033] Dry 360g of copolymerized polyoxymethylene in an oven at 90°C for 6 hours, add 40g of polyethylene oxide resin with a molecular weight of 500,000, 2g of antioxidant 1010, 2g of dicyandiamide, and 1.5g of magnesium hydroxide into a high-speed mixer and mix evenly Afterwards, melt blending and extrusion at a temperature of 210°C, the extrudate is rapidly cooled to below the crystallization temperature of polyoxyethylene, and the cooling rate is 50°C / min, and polyoxymethylene spherulites with a polyoxyethylene crystal layer intercalated are obtained. Polyoxymethylene material with intermediate structure. Its notched impact strength is 16kJ / m 2 , The tensile strength is 43MPa, the elongation at break is 82%, the friction coefficient is 0.17, and the wear scar width is 3mm.

Embodiment 3

[0035] Add 80g of polyethylene oxide resin with a molecular weight of 6.8 million, 320g of copolymerized polyoxymethylene, 1.8g each of nylon-6, magnesium hydroxide and melamine after drying at 90°C for 4 to 6 hours, and mix them in a high-speed mixer After uniformity, put it into a twin-screw extruder at a temperature of 210°C for melt blending and extrusion, and rapidly cool the extruded product below the crystallization temperature of polyethylene oxide at a cooling rate of 80°C / min to obtain crystallized polyethylene oxide A polyoxymethylene material with a structure in which layers are entrapped inside polyoxymethylene spherulites. Its notched impact strength is 14kJ / m 2 , The tensile strength is 45MPa, the elongation at break is 75%, the friction coefficient is 0.18, and the wear scar width is 4.03mm.

[0036] Table 1 is the mechanical properties and friction and wear properties of pure polyoxymethylene and modified polyoxymethylene of the present invention

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Wear scar width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com