3D printing reinforcement/Ti2AlNb base composite material and preparation method thereof

A composite material and 3D printing technology, applied in the field of metal material manufacturing, can solve problems such as the decline of the life and reliability of the whole system, poor wear resistance, etc., to eliminate defects, improve microhardness and friction and wear performance, and achieve dense structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

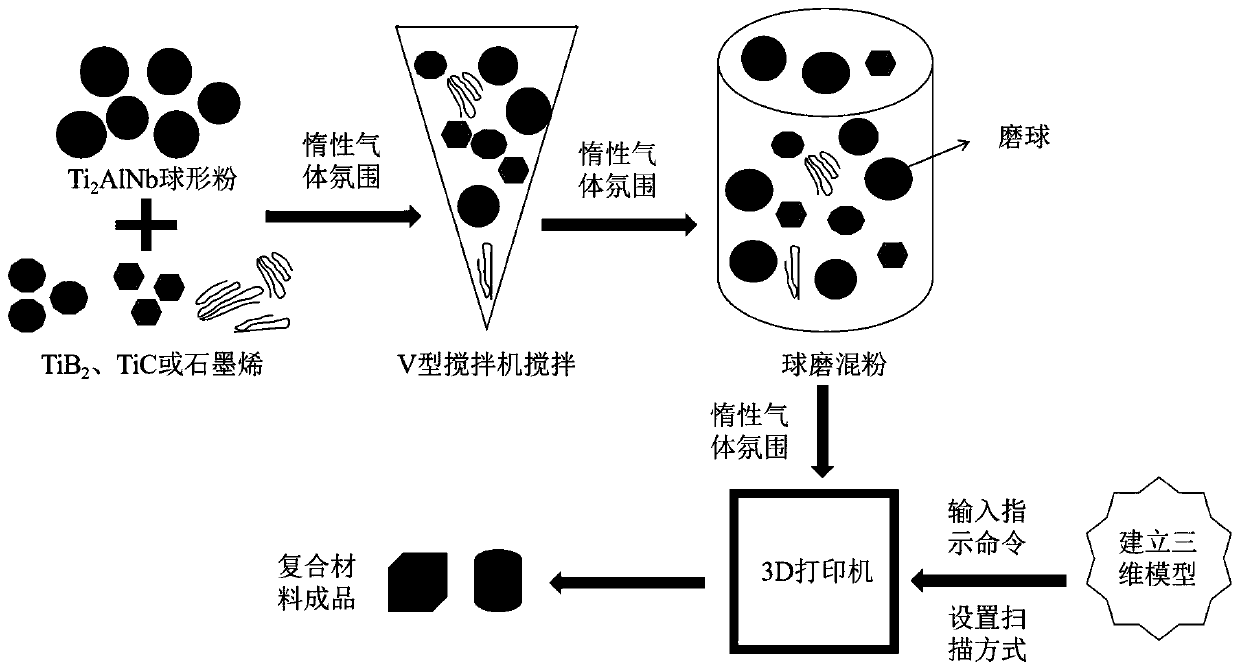

[0029] refer to figure 1 , a 3D printing reinforcement / Ti of the present invention 2 The preparation method of AlNb-based composite material, concrete steps are as follows:

[0030] (1) Selection of powder: select Ti prepared by rotating electrode method 2 AlNb spherical pre-alloyed powder as the matrix, with TiB 2 , Graphene carbon nanosheets or TiC powder are reinforcing particles;

[0031] (2) Pre-mixing of the mixed powder: the powder selected in step (1) is mixed according to the quality of the reinforced particles being 0.5wt.% to 25wt.% of the total mass of the mixed powder, put into a V-type mixer, and the V-type mixer is placed Under vacuum or inert gas atmosphere, carry out mechanical stirring for 30 minutes to 60 minutes;

[0032] (3) Ball milling and mixing: Put the pre-mixed powder obtained in step (2) into a ball mill jar made of stainless steel or zirconia and seal it. Inert gas, and then put the ball mill jar into the planetary ball mill for dry ball milli...

Embodiment 1

[0038] A 3D printed graphene / Ti 2 The preparation method of AlNb composite material is carried out according to the following steps:

[0039] (1) Selection of powder: select Ti prepared by rotating electrode method 2 AlNb spherical pre-alloyed powder as the matrix, with graphene nanosheets as reinforcing particles;

[0040] (2) Mixed powder pre-stirring: the powder selected in step (1) is graphene / Ti according to the quality of graphene (GNF) 2 Mix 0.5wt.% of the mass of AlNb mixed powder, put it into a V-shaped mixer, and place the V-shaped mixer under a vacuum atmosphere for mechanical stirring for 40 minutes;

[0041] (3) Ball milling and mixing: put the pre-mixed powder obtained in step (2) into a stainless steel ball mill tank for sealing, wherein the ball-to-material ratio is 10:1, and put the ball mill tank into a planetary ball mill after vacuuming , carry out dry ball milling to mix powder, set ball milling speed as 400r / min, ball milling time as 16h;

[0042] (4)...

Embodiment 2

[0046] A 3D printing TiC / Ti 2 The preparation method of AlNb composite material is carried out according to the following steps:

[0047] (1) Selection of powder: select Ti prepared by rotating electrode method 2 AlNb spherical pre-alloyed powder as the matrix, with TiC powder as the reinforcing particles;

[0048] (2) Pre-stirring of mixed powder: the powder selected in step (1) is TiC / Ti according to the quality of TiC 2 Mix 2wt.% of the AlNb mixed powder mass, put it into a V-shaped mixer, and place the V-shaped mixer under an argon atmosphere for mechanical stirring for 40 minutes;

[0049] (3) Ball milling and mixing: put the pre-mixed powder obtained in step (2) into a ball milling tank made of zirconia and seal it, wherein the ball-to-material ratio is 6:1, vacuumize and flush the ball milling tank with argon Put it into a planetary ball mill, carry out dry ball milling to mix powder, set the ball milling speed to 400r / min, and the ball milling time is 15h;

[0050]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com