Modified inorganic nanoparticle/epoxy resin composite material with higher friction and wear properties and preparation method thereof

A technology of inorganic nanoparticles and inorganic nanoparticles, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of poor friction and wear properties of epoxy resin, achieve convenient operation and improve friction and wear properties , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

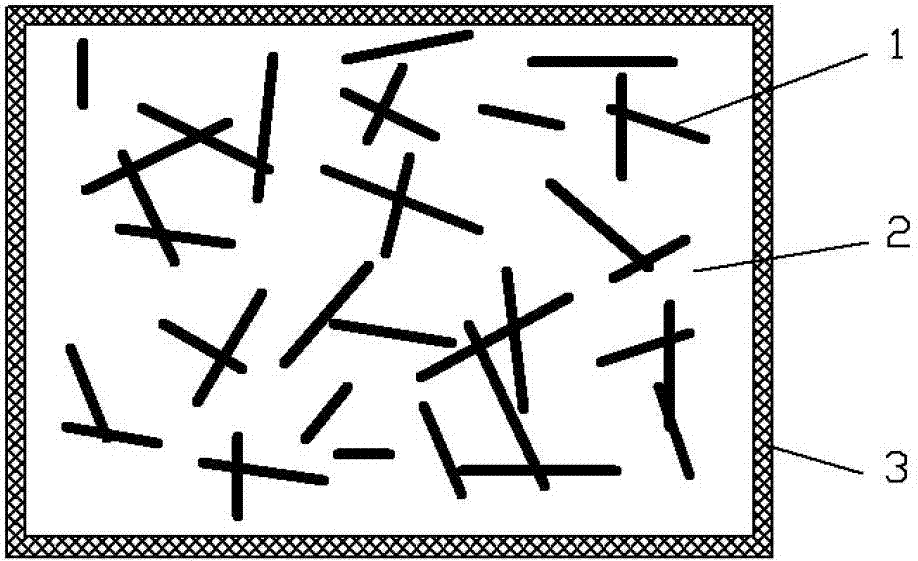

[0036] A modified inorganic nanoparticle / epoxy resin composite material with improved friction and wear properties, composed of the following components by mass percentage:

[0037] Epoxy resin 95%~99.9%

[0038] Modified inorganic nanoparticles 0.1%~5.0%

[0039] The total amount of the above components is 100%;

[0040] Wherein the epoxy resin is composed of 85%~95% epoxy resin and 5%~15% curing agent according to mass percentage.

[0041] The preparation method of the modified inorganic nanoparticle / epoxy resin composite material with improved friction and wear properties comprises the following steps:

[0042] 1. Modifying the inorganic nanoparticles: including the following steps:

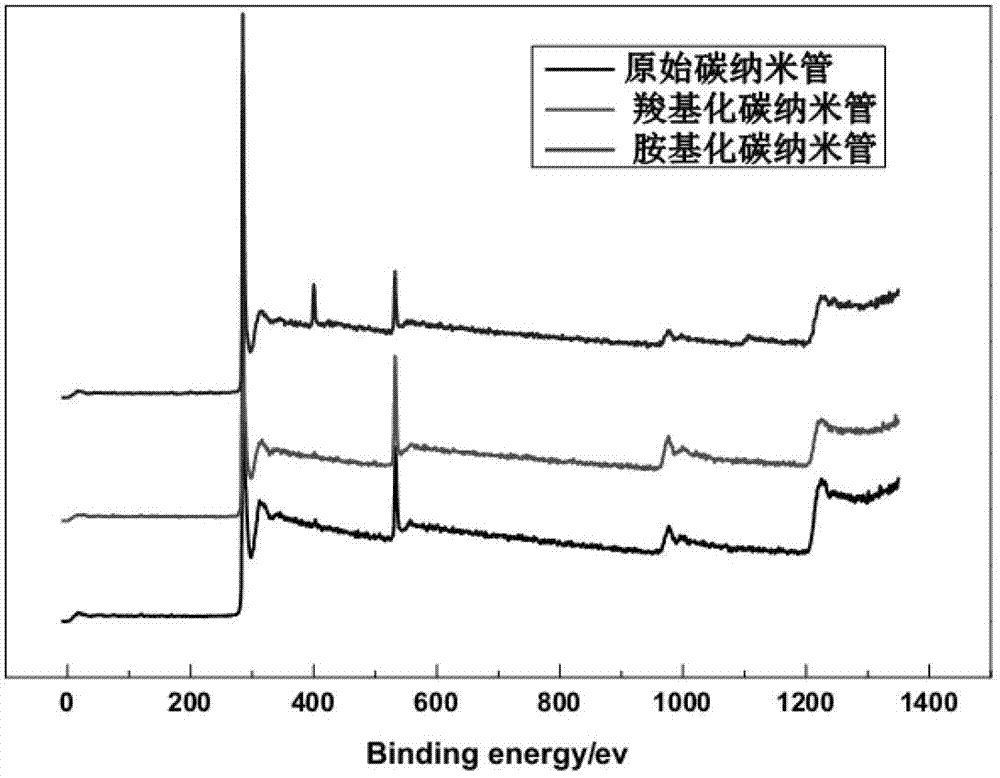

[0043] (1) Weighing 6 g of the original multi-walled carbon nanotubes (MWCNTs) and mixing them with 600 ml of mixed acid, and ultrasonically treating them for 10 h under ultrasonic waves of 1-200 kHz. The microporous membrane was suction-filtered and washed repeatedly until the filtrate wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com