Sizing material for sealing rotating shaft of fan

A technology for rotating shaft and sealing, which is applied in the field of rubber for fan rotating shaft sealing, can solve the problems of difficulty in secondary processing and grinding of the main shaft, difficulty in fine processing of huge shafts, and reduced life of seals, etc., and achieves ozone resistance and long-term resistance. Effects of improved aging performance, high weather resistance, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Embodiment and comparative example are prepared according to the following methods:

[0030] (1) Preparation method of rubber compound

[0031] (1) Preparation method of rubber compound

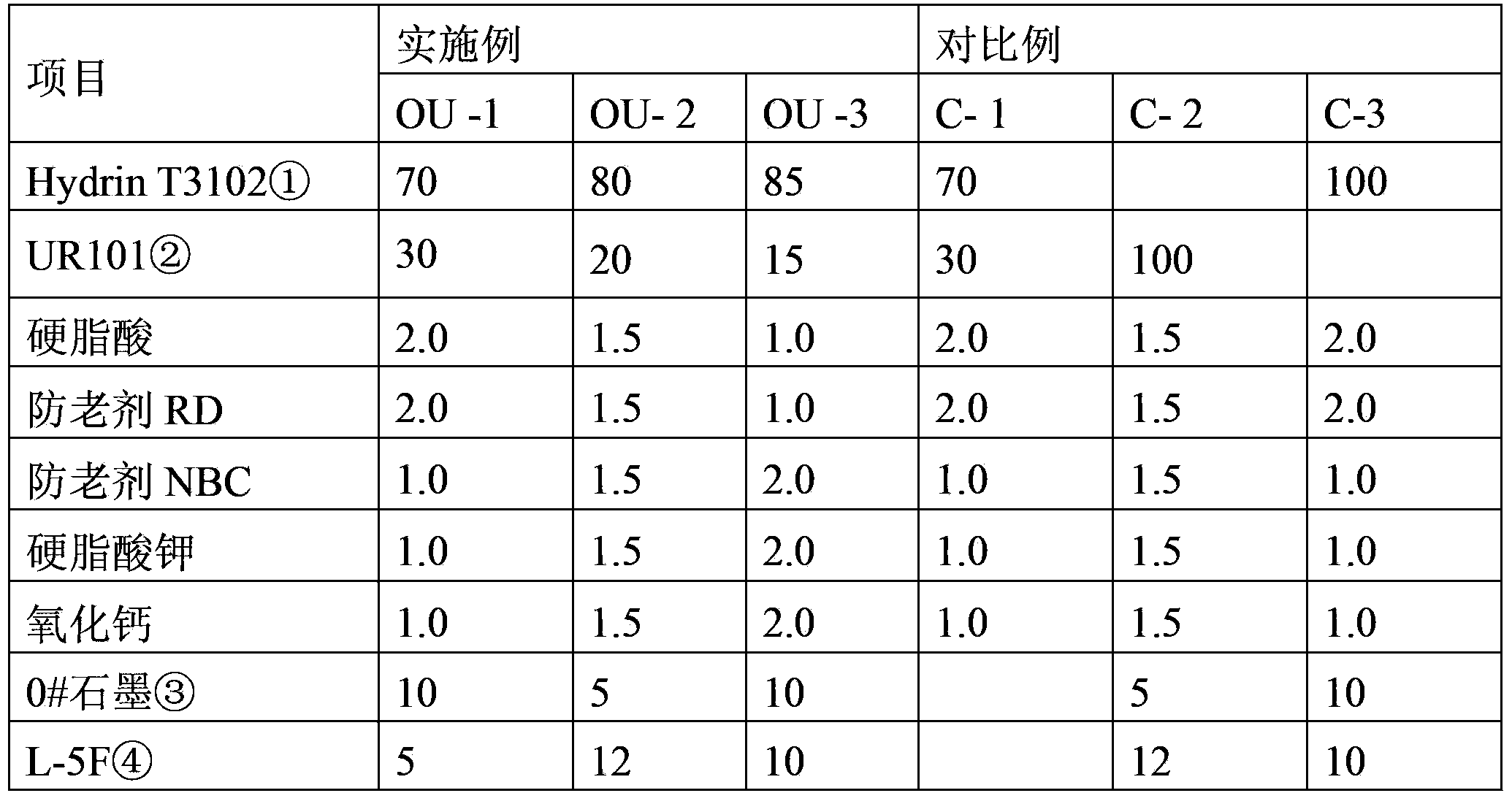

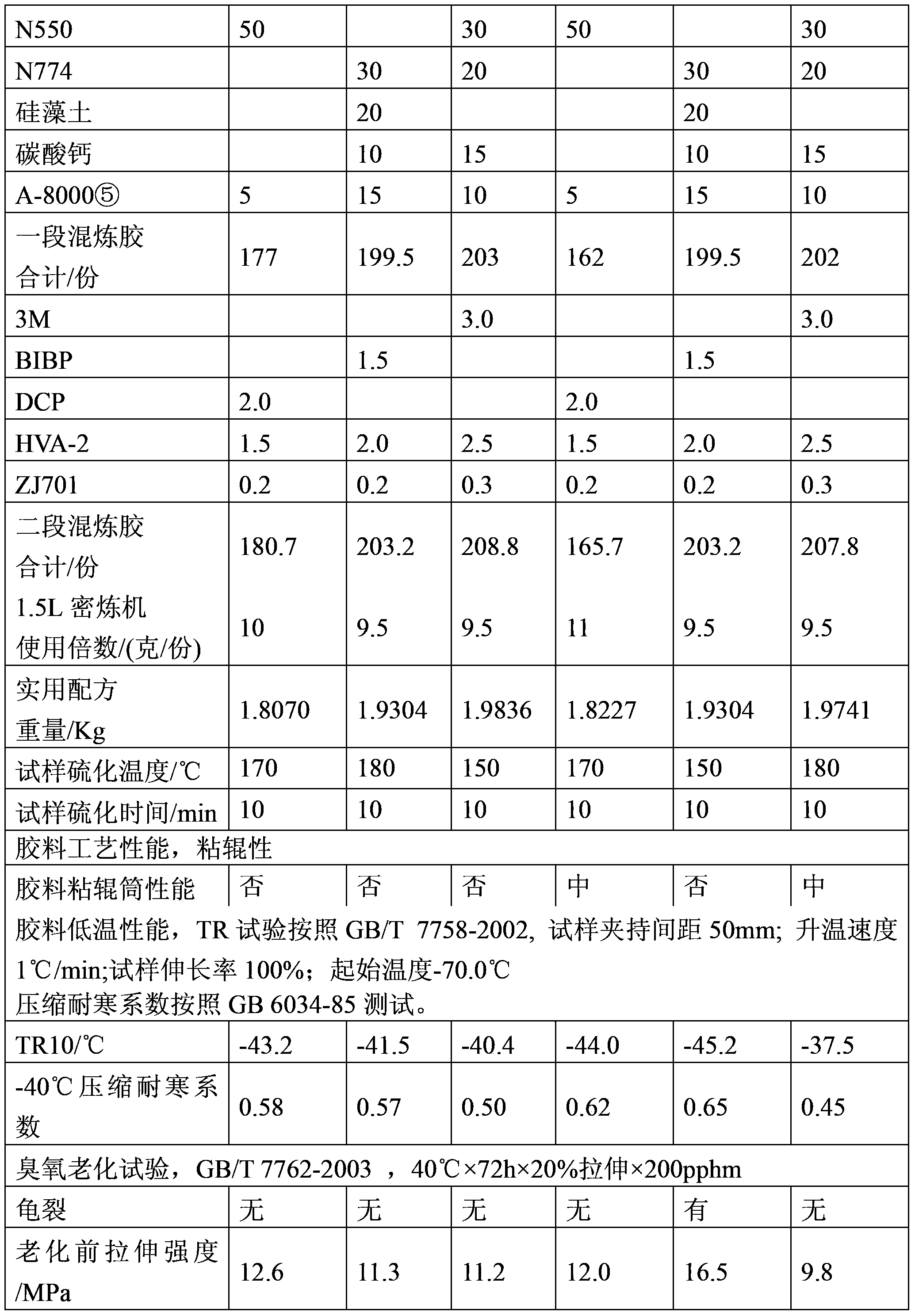

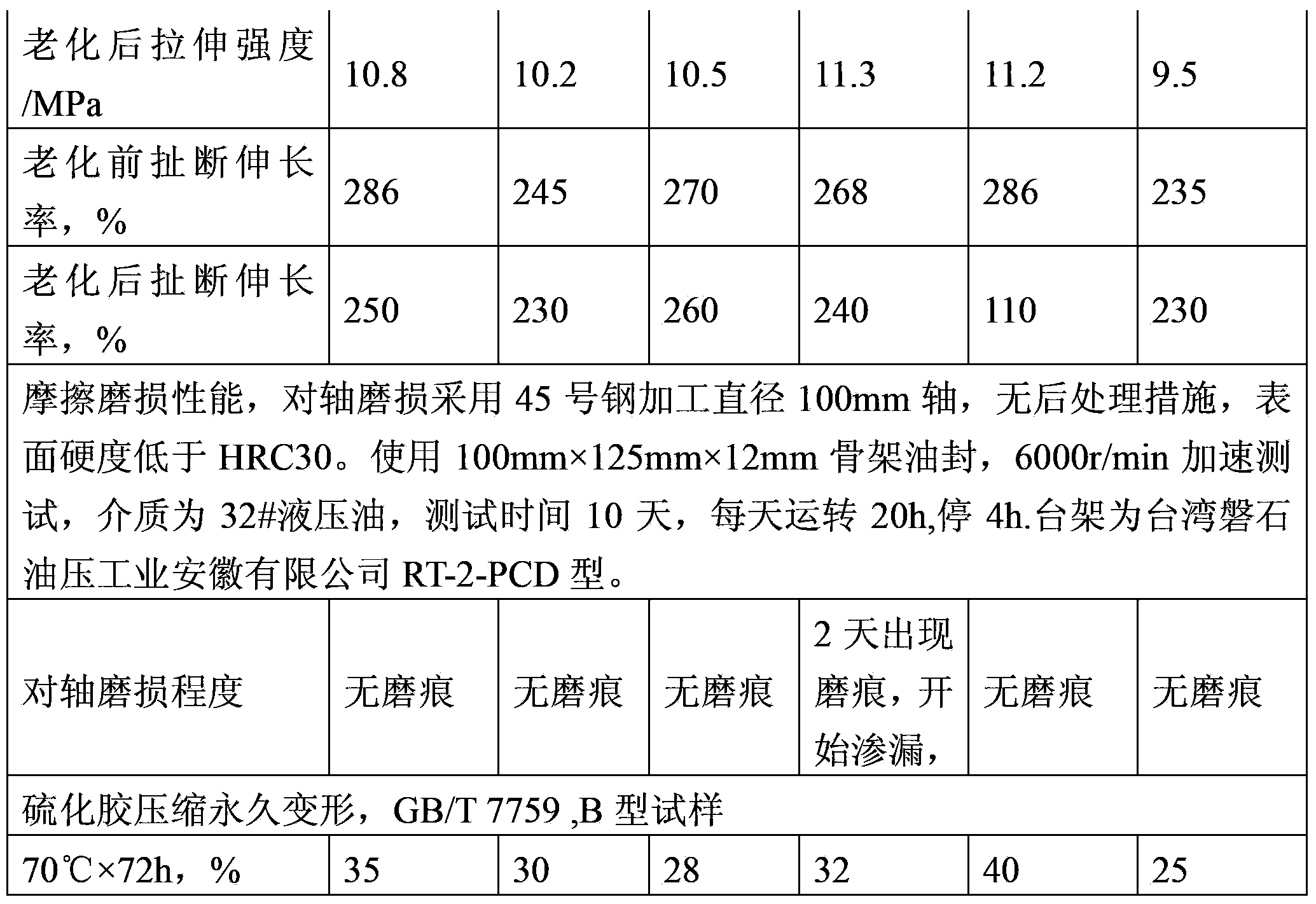

[0032] The rubber compound is produced by the ML-1.5L internal mixer of Baihong Machinery (Shanghai) Co., Ltd. The order of feeding is as follows: raw rubber and small materials are mixed for 2 minutes, carbon black is added and mixed for 4 minutes at room temperature, plasticizer and Filler mixing temperature reaches 130°C to remove glue, let it stand for more than 24 hours to obtain a section of mixed rubber; put a section of mixed rubber and the remaining components into the ML-1.5L internal mixer, and mix for about 90 seconds from room temperature , When the temperature reaches 105°C, the glue is discharged to obtain the mixed rubber. See Table 1 for the amounts and specific sampling sequences of the components of OU-1, OU-2 and OU-3 three groups of embodiments. At the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com