Carbon fiber/copper composite material and preparation method thereof

A composite material and carbon fiber technology, which is applied in the field of carbon fiber/copper composite materials and preparation, can solve the problems of high cost and complicated preparation process, and achieve the effects of low cost, simplified process and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

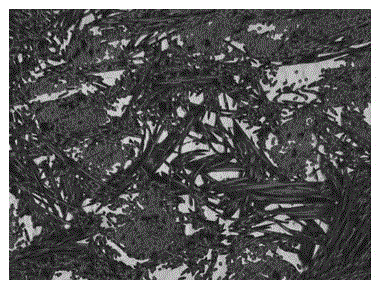

Image

Examples

Embodiment approach 1

[0014] Weigh polypropylene nitrile carbon fiber and 20wt% phenolic resin, press into 0.7 g / cm 3 heat treatment at 2200°C; prepare an infiltration agent with a mass ratio of Cu / Zr of 9:1; embed the carbon body with the prepared infiltration agent, and keep it warm at 1250°C for 30 minutes under vacuum conditions , to prepare carbon fiber / copper composites.

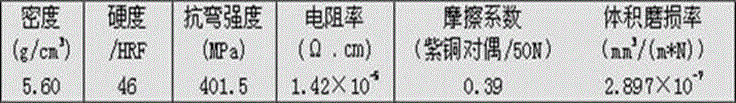

[0015]

Embodiment approach 2

[0017] Weigh polypropylene nitrile carbon fiber and 20wt% phenolic resin, press into 1.32 g / cm 3 heat treatment at 2400°C; prepare an infiltration agent with a mass ratio of Cu / Zr of 87:13; embed the carbon body with the prepared infiltration agent, and keep it warm at 1300°C for 30 minutes under vacuum conditions , to prepare carbon fiber / copper composites.

[0018] Its main performance indicators are shown in the table below:

[0019]

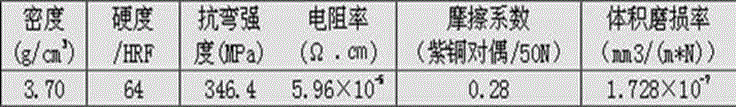

Embodiment approach 3

[0021] Weigh polypropylene nitrile carbon fiber and 20wt% phenolic resin, press into 1.5g / cm 3 heat treatment at 2500°C; prepare an infiltration agent with a mass ratio of Cu / Zr of 85:15; embed the carbon body with the prepared infiltration agent, and keep it warm at 1350°C for 30 minutes under vacuum , to prepare carbon fiber / copper composites.

[0022] Its main performance indicators are shown in the table below:

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com