Preparation method of self-lubricating ceramic cutting tool material comprising spherical nanometer silicon dioxide coated hexagonal boron nitride composite powder

The technology of nano-silica and spherical silica is applied in the field of self-lubricating ceramic tool materials, which can solve the problems of easy agglomeration of self-lubricating ceramic tool materials, low mechanical properties of solid lubricant particles, and poor matrix bonding. Achieve the effect of inhibiting the growth of grains, good self-lubricating performance, and good high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

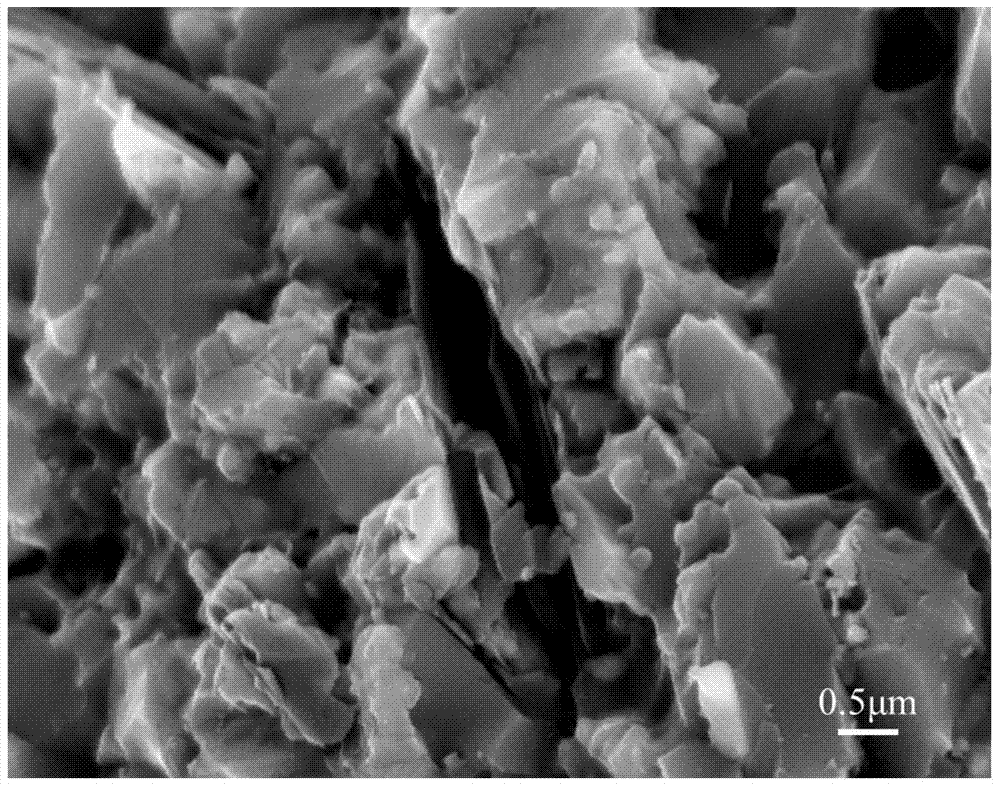

[0032] Example 1, adding spherical nano-silica coated hexagonal boron nitride composite powder self-lubricating ceramic tool material, the volume percentage of each component material is: Al 2 o 3 66.15%, TiC 28.35%, h-BNSiO 2 5%, MgO 0.5%. The preparation steps are as follows:

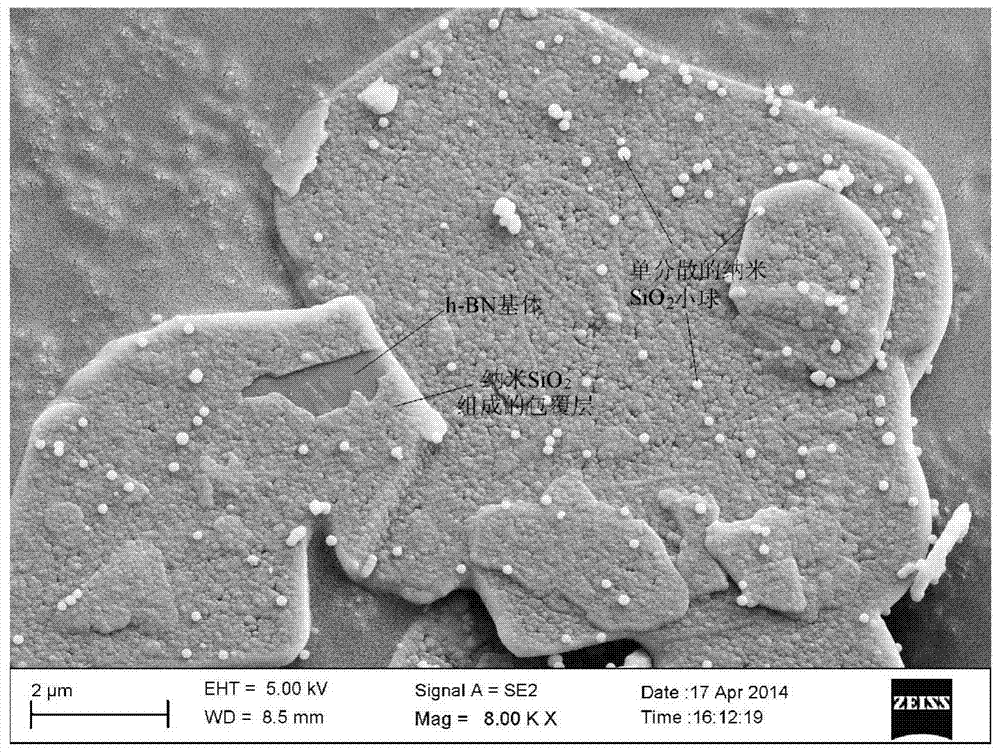

[0033] (1)h-BNSiO 2 Preparation of composite powder:

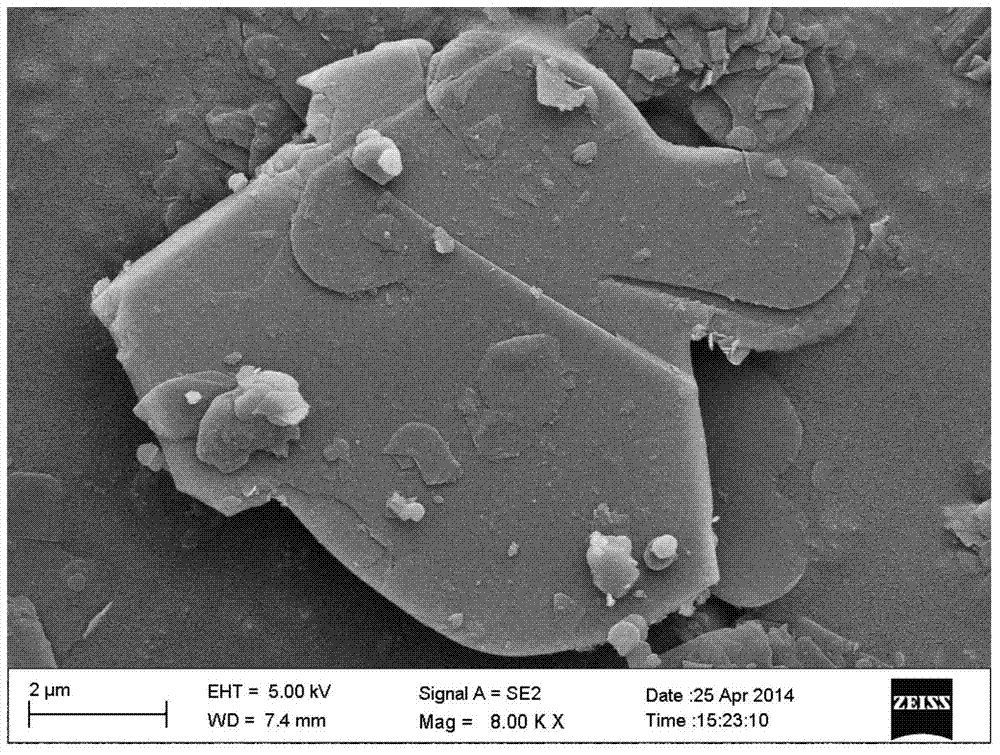

[0034] Weigh 1 g of h-BN micron powder with an average particle size of 10 μm and disperse it in 100 mL of absolute ethanol, ultrasonically disperse for 10 min, add 4.5 mL of distilled water and 4 mL of ammonia water, the pH value is about 8.5, and transfer the obtained mixture into three In the flask, stir magnetically and heat in a water bath until the temperature is 45°C. Keeping the temperature at 45°C, add ethyl orthosilicate dropwise to the above mixed solution. The dropping method is as follows: divide 12mL of ethyl orthosilicate into 3 parts, and add one part of ethyl orthosilicate dropwise within 1.5h; After 0.5h, add the second por...

Embodiment 2

[0042] A self-lubricating ceramic tool material with spherical nano-silica coated hexagonal boron nitride composite powder, the volume percentage of each component is: Al 2 o 3 62.65%, TiC 26.85%, h-BNSiO 2 10%, MgO 0.5%. The preparation steps are as follows:

[0043] (1) with embodiment 1;

[0044] (2) Weigh an appropriate amount of Al in proportion 2 o 3 and TiC, respectively, dispersed in absolute ethanol, ultrasonically dispersed and mechanically stirred for 20 minutes, after mixing the obtained suspension, adding a certain amount of MgO, ultrasonically dispersed again and mechanically stirred for 20 minutes to obtain a uniformly mixed multi-phase suspension;

[0045] (3) Pour the above-mentioned multi-phase suspension into the ball mill pot, add cemented carbide balls to ensure that the weight ratio of balls to materials is 12:1, fill in nitrogen as a protective atmosphere and continue ball milling for 48 hours;

[0046] (4) Add h-BNSiO in proportion 2 The composit...

Embodiment 3

[0050] A self-lubricating ceramic tool material with spherical nano-silica coated hexagonal boron nitride composite powder, the volume percentage of each component is: Al 2 o 3 47%, TiC 47%, h-BNSiO 2 5%, MgO 1%. The preparation steps are as follows:

[0051] (1) with embodiment 1;

[0052] (2) Weigh Al in proportion 2 o 3 and TiC, and respectively dispersed in absolute ethanol, ultrasonically dispersed and mechanically stirred for 15 minutes, the obtained suspension was mixed, an appropriate amount of MgO was added, and then ultrasonically dispersed and mechanically stirred for 15 minutes to obtain a uniformly mixed multi-phase suspension;

[0053] (3) Pour the above-mentioned multi-phase suspension into the ball mill pot, add cemented carbide balls to ensure that the weight ratio of balls to materials is 10:1, fill in nitrogen as a protective atmosphere and continue ball milling for 36 hours;

[0054] (4) Add h-BNSiO in proportion 2 The composite powder was ball mille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com