Ordered mesoporous metal oxide material with ultra-large aperture and preparation method thereof

An oxide and mesoporous technology, applied in the field of ordered mesoporous metal oxide materials and their preparation, can solve problems such as narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

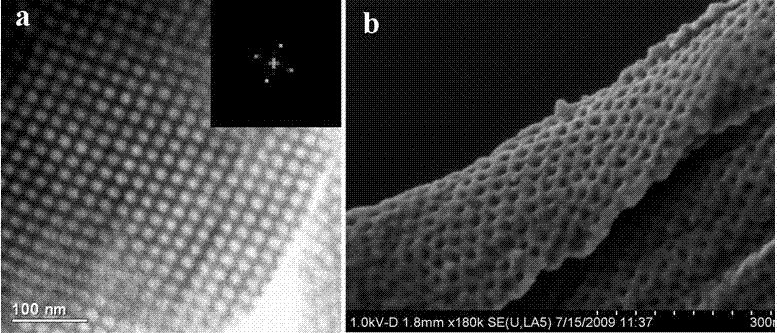

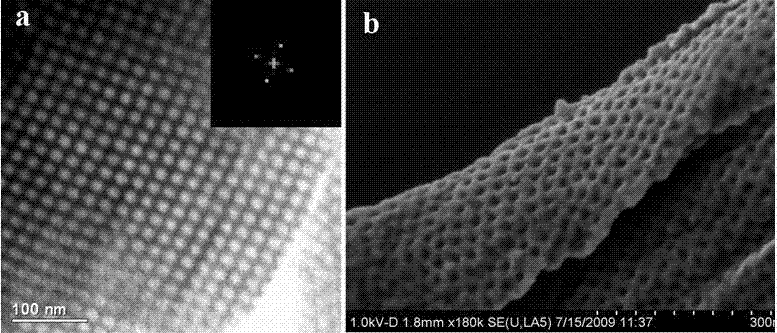

[0020] Example 1: (synthesis of mesoporous titania material with ultra-large pore size)

[0021] 0.10 g PEO- b -PS was dissolved into 5.0 g (61.7 mmol) THF solution and stirred to obtain a homogeneous solution A (2.0 wt %). Dissolve 0.6 g (2.1 mmol) TIPO in 0.9 g acetylacetone (AcAc) solution to obtain a light red solution B, then mix the two solutions A and B, then add 0.6 g concentrated hydrochloric acid (37 wt %), and stir for 30 min .

[0022] Transfer the obtained deep red solution to a petri dish, and after volatilizing at room temperature for 5 min, transfer the petri dish to a 40°C oven to further volatilize the solvent for 24 h, then raise the temperature of the oven to 100°C for curing for 24 h, A light yellow transparent composite film was obtained. The film was scraped off the Petri dish to give a pale yellow powder.

[0023] The newly prepared sample was placed in a tube furnace and roasted at 350-600 °C for 3 h under a nitrogen atmosphere. The heating rate wa...

Embodiment 2

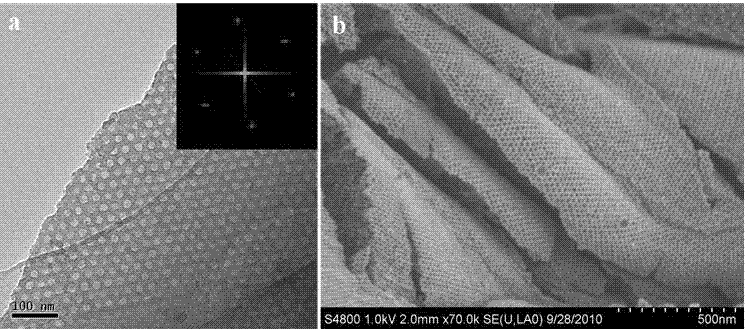

[0024] Example 2: (synthesis of alumina material with ultra-large pore diameter mesoporous)

[0025] 0.10 g PEO- b -PS was dissolved into 5.0 g (61.7 mmol) THF solution to obtain a colorless homogeneous solution A (2.0 wt %). Dissolve 0.72 g (2.2 mmol) of aluminum acetylacetonate in 2.58 g of tetrahydrofuran (THF), stir evenly to obtain solution B, mix the two solutions of A and B, and drop 0.3 g of concentrated nitric acid into the system while vigorously stirring ( 67.0 wt %), after stirring for 12 h, a colorless and transparent solution was obtained.

[0026] Transfer the solution to a petri dish, volatilize at room temperature for 5 min, then transfer to a 50°C oven to evaporate the solvent for 24 h, and then heat up to 100°C to solidify for 24 h, and remove the obtained light yellow transparent composite film from the petri dish Scrape off to obtain light yellow fresh sample powder.

[0027] The newly prepared samples were placed in a tube furnace, under the protection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com