Hydrolysis method in technique for synthesizing polyacrylamide with super molecular weight

A technology of polyacrylamide and ultra-high molecular weight, which is applied in the field of hydrolysis and granulation technology, and can solve the problems of high purity requirements of raw materials, high requirements, and difficulty in producing high molecular weight products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

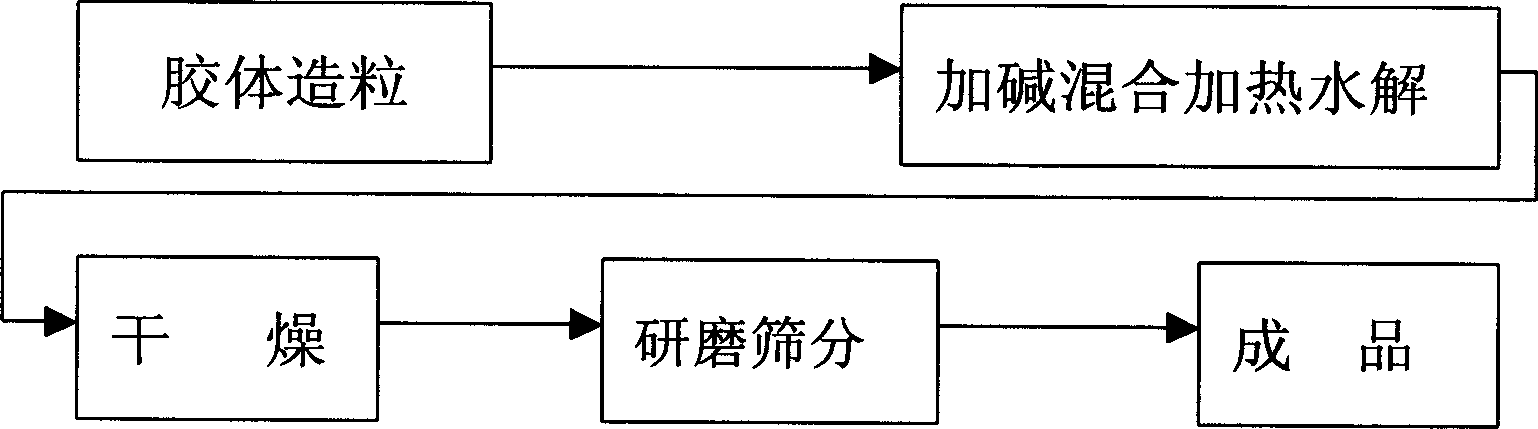

Method used

Image

Examples

Embodiment 1

[0014] The hydrolysis process of this process is illustrated below with 5 12 tons / still.

[0015] Processing capacity

Embodiment 2

[0017] Verify the technological process with 5 reactions of 4 tons / pot:

[0018] Processing capacity

[0019] The invention of this technology makes the molecular weight of polyacrylamide reach more than 28 million, the dissolution rate of the product is less than 2 hours, the viscosity is more than 70mPa.s, the preparation of 4000 salinity aqueous solution, the viscosity is equivalent to the molecular weight of 12 million and the preparation effect of 1000 salinity sewage is achieved. Above 40mPa.s, it solves the problem of preparing polymers from sewage in Daqing Oilfield, saves a lot of fresh water and reduces sewage discharge. The social and economic benefits are remarkable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com