Rubber reinforcing agent, preparation method thereof, and preparation method of butadiene styrene rubber

A technology of rubber reinforcing agent and substituent is applied in the field of preparation of high-strength styrene-butadiene rubber, which can solve the problems of difficult to control polymerization process, complex polymerization monomer components, and large difference in monomer reactivity ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

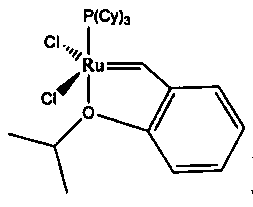

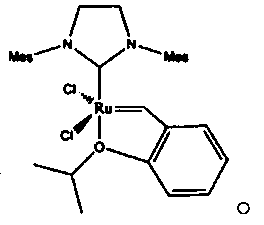

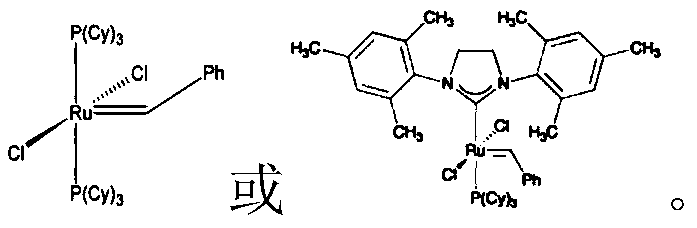

[0053] Styrene and vinyltriethoxysilane monomers are mixed at a molar ratio of 1:1, and a monomer solution with a mass concentration of 10% is configured with toluene solvent, and 0.01% mol of the monomer is added to the solution Catalyst, isolated from air and water, after reacting at 25°C for 2 hours, use a vacuum desolventizer to remove the toluene solvent to obtain a styrene-butadiene rubber reinforcing agent.

[0054] Add styrene-butadiene latex (100 parts on a dry basis), 5 parts by mass of the above-mentioned rubber reinforcing agent and 0.01 parts by mass of potassium persulfate initiator to the polymerization kettle, control the reaction temperature to 60 ° C, and react for 3 hours. After the reaction, The emulsion is coagulated, washed and dried to obtain high-strength styrene-butadiene rubber products. After testing, compared with the tensile strength of ordinary styrene-butadiene rubber (18.6MPa), the tensile strength of the reinforced styrene-butadiene rubber in ...

Embodiment 2

[0059] Mix styrene and vinyldiethoxymethylsilane monomers in a molar ratio of 1:0.1, configure a monomer solution with a mass concentration of 30% with toluene solvent, and add 0.04% mol of monomers to the solution Catalyst, isolated from air and water, after reacting at 25°C for 8 hours, use a vacuum desolventizer to remove the toluene solvent to obtain a styrene-butadiene rubber reinforcing agent.

[0060] Add styrene-butadiene latex (100 parts on a dry basis), 45 parts by mass of the above-mentioned rubber reinforcing agent and 0.1 parts by mass of benzoyl peroxide initiator to the polymerization kettle, control the reaction temperature to 40 ° C, and react for 5 hours. The reacted emulsion is coagulated, washed and dried to obtain a high-strength styrene-butadiene rubber product. After testing, compared with the tensile strength of ordinary styrene-butadiene rubber (19.6MPa), the tensile strength of the reinforced styrene-butadiene rubber in Example 2 is 25.9MPa, which is...

Embodiment 3

[0065] Mix methylstyrene and vinyltrimethoxysilane monomers at a molar ratio of 1:5, configure a monomer solution with a mass concentration of 1% with toluene solvent, and add 0.10% mol of the monomer to the solution Catalyst, isolated from air and water, after reacting at 25°C for 0.5h, use a vacuum desolventizer to remove the toluene solvent to obtain a styrene-butadiene rubber reinforcing agent.

[0066] Add styrene-butadiene latex (100 parts on a dry basis), 15 parts by mass of the above-mentioned rubber reinforcing agent and 0.08 parts by mass of cumene peroxide initiator to the polymerization kettle, control the reaction temperature to 65 ° C, and react for 10 h. The reacted emulsion is coagulated, washed and dried to obtain a high-strength styrene-butadiene rubber product. After testing, compared with the tensile strength of ordinary styrene-butadiene rubber (20.1 MPa), the tensile strength of the reinforced styrene-butadiene rubber in Example 3 is 25.5 MPa, which is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com