High-fluidity metallocene low-density polyethylene resin graft and preparation method thereof

A low-density polyethylene and high-fluidity technology, which is applied in the field of high-fluidity metallocene low-density polyethylene resin grafts and their preparation, can solve the problem of low fluidity and grafting rate of the grafts, and it is difficult to obtain high MFR and high grafting rate grafts, etc., to achieve the effect of high fluidity and mechanical strength, low melt strength, and high grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

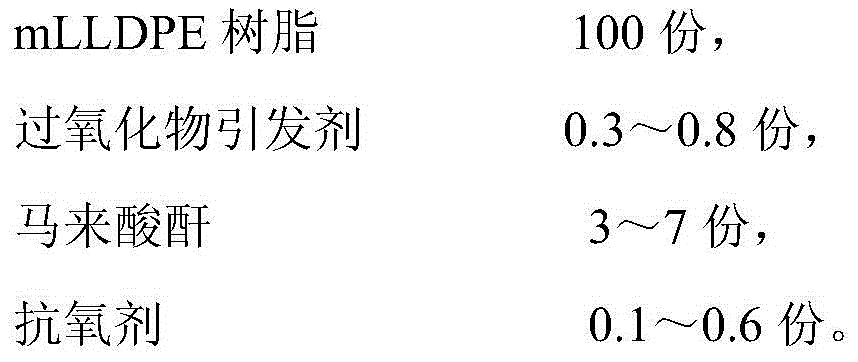

[0046] Prepare a kind of high fluidity metallocene low density polyethylene resin graft, comprise the raw material of following parts by weight:

[0047]

[0048] The preparation method comprises the following steps:

[0049] (1) Dissolve the peroxide initiator and maleic anhydride in acetone first, then add the solution to the mLLDPE resin and antioxidant, mix well, leave it open for 12 hours to make the acetone completely volatilize; The mass ratio of solvent to acetone is 2:95.

[0050] (2) Pour the material obtained in step (1) into the hopper of an automatic feeder, and feed it into a twin-screw reaction extruder with a screw length-to-diameter ratio (L / D) of 48:1, with a screw diameter of 40 mm, and extrude Temperature: The melt mixing and dispersing section is: 100°C (feeding section), 110°C, 120°C, 125°C; the reaction section is 150°C, 170°C, 180°C, 190°C, 200°C; ℃, 180℃ (head mold), the screw arrangement of the reaction section is narrow pitch thread element-stra...

Embodiment 2

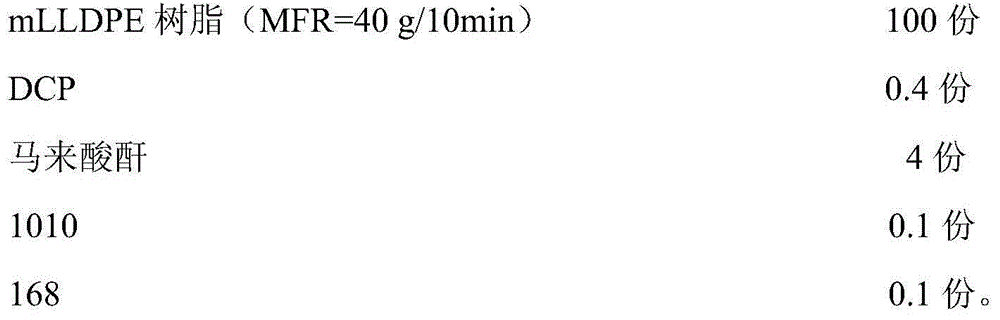

[0053] Prepare a kind of high fluidity metallocene low density polyethylene resin graft, comprise the raw material of following parts by weight:

[0054]

[0055] Example 2 adopts the same preparation method as Example 1.

Embodiment 3

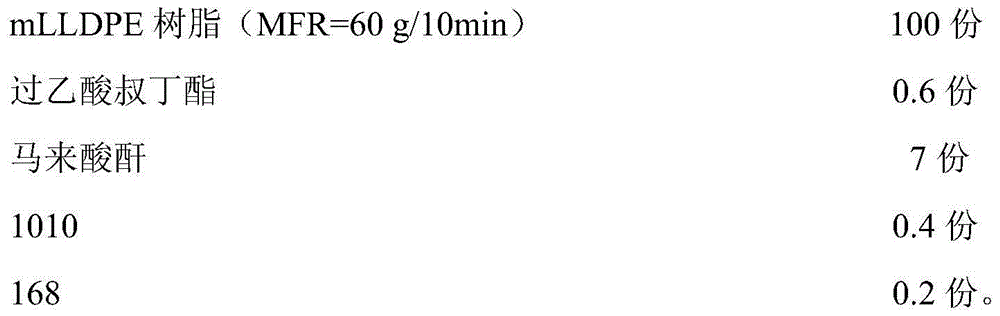

[0057] Prepare a kind of high fluidity metallocene low density polyethylene resin graft, comprise the raw material of following parts by weight:

[0058]

[0059] Example 3 uses the same preparation method as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com