Acetoacetyl modified polyvinyl alcohol as well as preparation method and application thereof

An acetoacetyl group, polyvinyl alcohol technology, applied in the direction of unsaturated alcohol copolymer adhesives, monocarboxylic acid ester copolymer adhesives, adhesive types, etc., can solve environmental and human health hazards, diketene High activity, strong toxicity of diketene, etc., to achieve stable raw material properties, improve bonding strength, and ensure the effect of working environment and physical health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of PVA

[0044] Polymerize 70 parts of vinyl acetate and 150 parts of methanol in the presence of 0.055 parts of AIBN. The polymerization temperature is 60°C. When the polymerization reaction ends, the residual sheet is blown out to obtain comonomers. Take a part of the comonomers and adjust the concentration to 15wt% methanol solution was alcoholysed with 40g / L sodium hydroxide methanol solution, dried and pulverized to obtain polyvinyl alcohol powder.

[0045] We have carried out following detection to the polymkeric substance synthesized in embodiment 1:

[0046] Determination of average degree of polymerization

[0047] According to GB 12010.9-89, the degree of polymerization of the PVA prepared in Example 1 was measured, and the average degree of polymerization of PVA was measured to be 962.

[0048] Determination of degree of alcoholysis

[0049] According to GB 12010.5-89 method, test its degree of alcoholysis:

[0050] Its calculation formula is:...

Embodiment 2

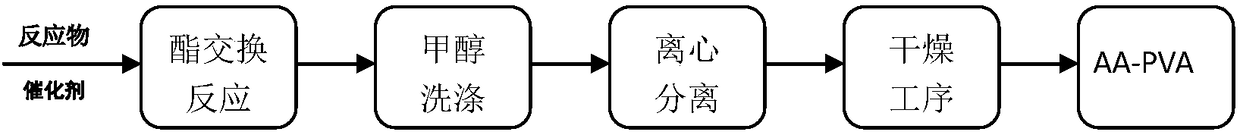

[0054] Preparation of AA-PVA

[0055] Add 100 parts of PVA 40 mesh powder to the kneader with temperature control system, replace with nitrogen for 3 minutes, then start stirring, raise the temperature to 100°C, keep the temperature constant, add 15 parts of acetic acid to it, and after it is mixed evenly, add 26.7 parts dropwise Parts of t-BAA (dropped for 1h), after the t-BAA was added dropwise, further reacted for 1h to stop the reaction.

[0056] Washing and Separation of AA-PVA

[0057] The above reaction product was washed with methanol, and then centrifuged to obtain AA-PVA powder.

[0058] Drying of AA-PVA

[0059] The AA-PVA powder separated above was dried for 120 min at a pressure of 20 kPa and a temperature of 95° C. to obtain the final product AA-PVA powder.

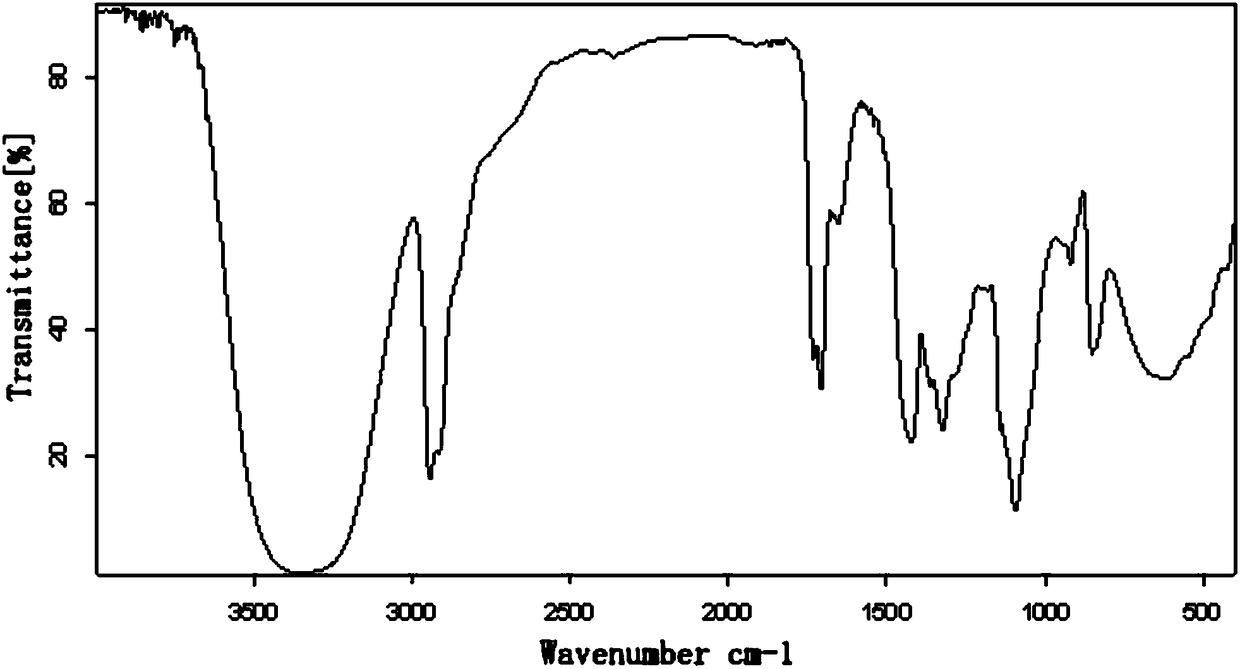

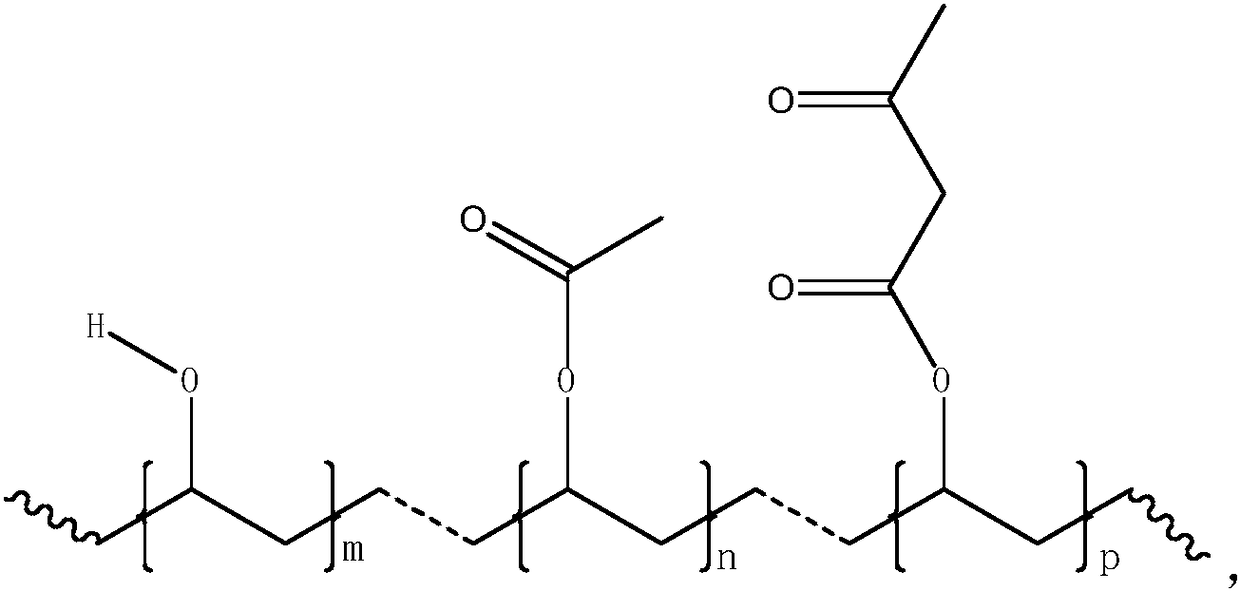

[0060] Analytical characterization of AA-PVA

[0061] In order to analyze and confirm the structural formula of the obtained modified polyvinyl alcohol, we have carried out the following detection to the...

Embodiment 3

[0072] AA-PVA of the present invention is used as PVAc emulsion polymerization protective colloid and uses:

[0073] Add the AA-PVA product (6 parts) and deionized water (135 parts) synthesized in Example 2 into a three-necked flask equipped with a reflux device, a stirrer, a dropping funnel and a thermometer, start the stirrer, and heat up to 90°C , after it is completely dissolved, cool down to 40°C, add OP-10 (1 part) and stir for 10 minutes, then add vinyl acetate (10% of the total amount, 6 parts) and ammonium persulfate (25% of the total amount, 0.12 parts), continue to stir and heat in a water bath, and control the reaction temperature at 80°C. After the initiation reaction starts, the remaining vinyl acetate is added dropwise within 3 hours, and the remaining ammonium persulfate solution is added dropwise within 3.2 hours; after all the feeding is completed, continue the heat preservation reaction without reflux. Cool to room temperature, add sodium bicarbonate (0.3 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com