Preparation method of teflon composite substrate material

A polytetrafluoroethylene and composite substrate technology, which is applied in the field of organic/inorganic composite materials, can solve the problems of water absorption data reporting and high water absorption of composite substrate materials, and achieve improved compatibility, improved dispersion uniformity, low dielectric The effect of electrical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

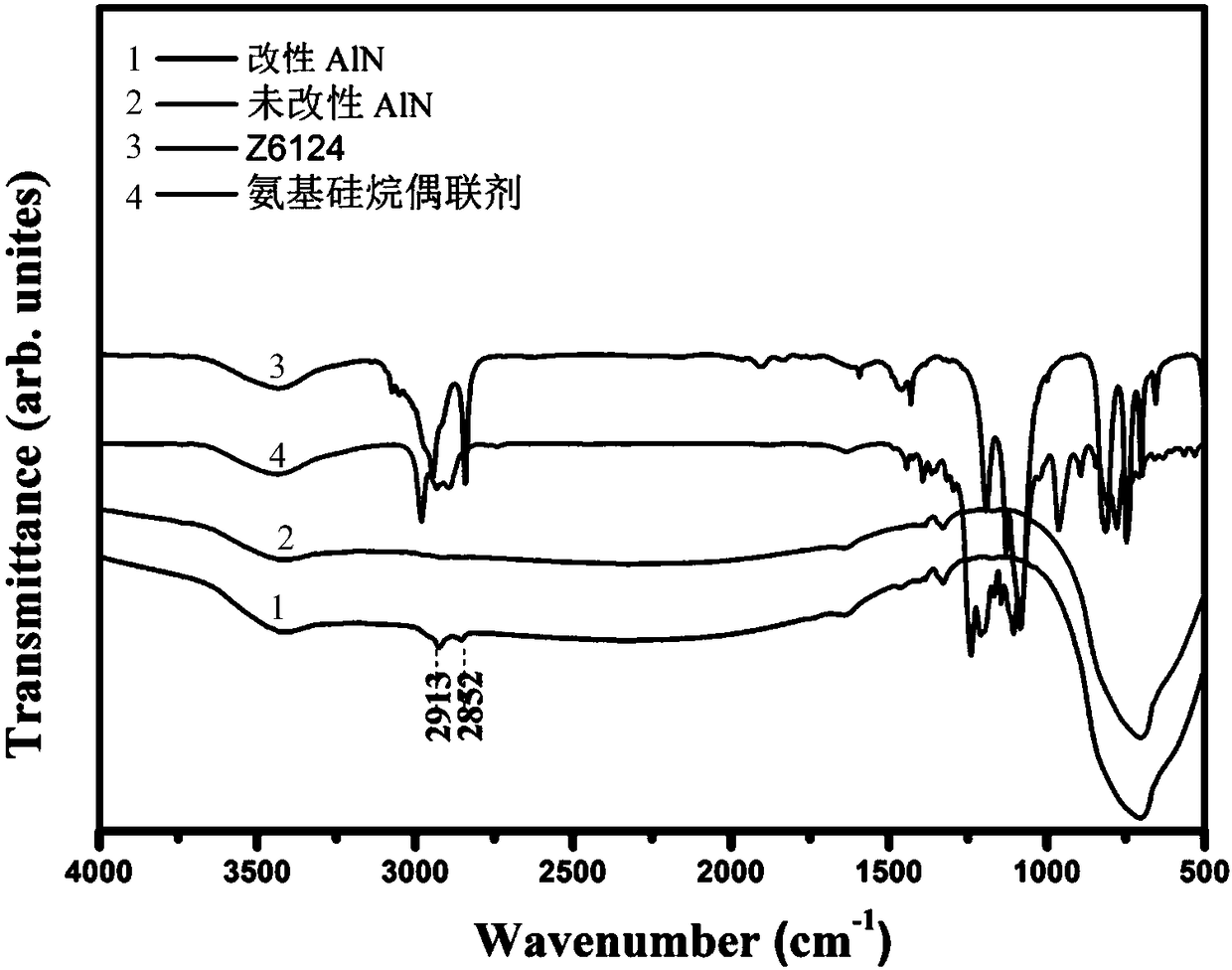

[0047] a) Weigh 400g of aluminum nitride powder, put it into a high-temperature pre-sintering furnace, and simultaneously pass a mixed gas of dry oxygen and inert gas, and oxidize at 1000°C for 2h. Weigh 62.5g of deionized water and 237.5g of alcohol, then add glacial acetic acid to the mixed solution of deionized water and alcohol to adjust pH=4. Weigh 200g of aluminum nitride ceramic powder after heat treatment, weigh 2g of F8261 coupling agent, 1g of KH602 coupling agent, add aluminum nitride ceramic powder and coupling agent to the above deionized water and alcohol mixture, 55 ℃ Stir ultrasonically for 1.5h. The solid obtained by filtering the mixed solution was dried in an oven at 120° C. for 6 hours, and sieved with a 120-mesh standard sampling sieve to obtain a modified powder. (F8261: KH602: AlN=1:0.5:100)

[0048] b) Weigh the polytetrafluoroethylene emulsion according to the aluminum nitride ceramic powder weight ratio of 5.0%, and dilute the emulsion concentration...

Embodiment 2

[0052] a) Weigh 400g of aluminum nitride powder, put it into a high-temperature pre-sintering furnace, and simultaneously pass a mixed gas of dry oxygen and inert gas, and oxidize at 1000°C for 2h. Weigh 62.5g of deionized water and 237.5g of alcohol, then add glacial acetic acid to the mixed solution of deionized water and alcohol to adjust pH=4. Weigh 200g of aluminum nitride ceramic powder after heat treatment, weigh 2g of F8261 coupling agent, 0.6g of KH602 coupling agent, add aluminum nitride ceramic powder and coupling agent to the above-mentioned deionized water and alcohol mixture, 55 ℃ ultrasonic stirring for 1.5h. The solid obtained by filtering the mixed solution was dried in an oven at 120° C. for 6 hours, and sieved with a 120-mesh standard sampling sieve to obtain a modified powder. (F8261: KH602: AlN=1:0.3:100)

[0053] b) Weigh the polytetrafluoroethylene emulsion according to the aluminum nitride ceramic powder weight ratio of 5.0%, and dilute the emulsion c...

Embodiment 3

[0057] a) Weigh 400g of aluminum nitride powder, put it into a high-temperature pre-sintering furnace, and simultaneously pass a mixed gas of dry oxygen and inert gas, and oxidize at 1000°C for 2h. Weigh 62.5g of deionized water and 237.5g of alcohol, then add glacial acetic acid to the mixed solution of deionized water and alcohol to adjust pH=4. Weigh 200g of heat-treated aluminum nitride ceramic powder, weigh 2g of Z-6124 coupling agent, and 0.4g of KH602 coupling agent, and add aluminum nitride ceramic powder and coupling agent to the above deionized water and alcohol mixture , 55 ℃ ultrasonic stirring 1.5h. The solid obtained by filtering the mixed solution was dried in an oven at 120° C. for 6 hours, and sieved with a 120-mesh standard sampling sieve to obtain a modified powder. (Z-6124: KH602: AlN=1:0.2:100)

[0058] b) Weigh the polytetrafluoroethylene emulsion according to the aluminum nitride ceramic powder weight ratio of 5.0%, and dilute the emulsion concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| dielectric properties | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com