Modified starch adhesive and preparation method thereof

A starch adhesive and modified technology, applied in the directions of adhesives, adhesive types, graft polymer adhesives, etc., can solve problems such as poor bonding strength, water resistance and stability, and achieve low cost and benefit for grafting reaction. , Improve the effect of grafting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

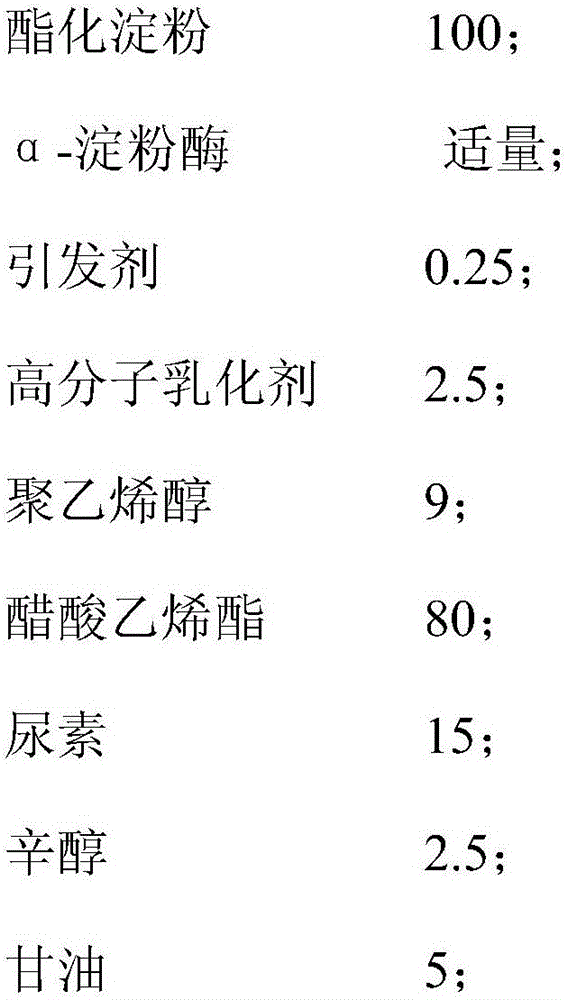

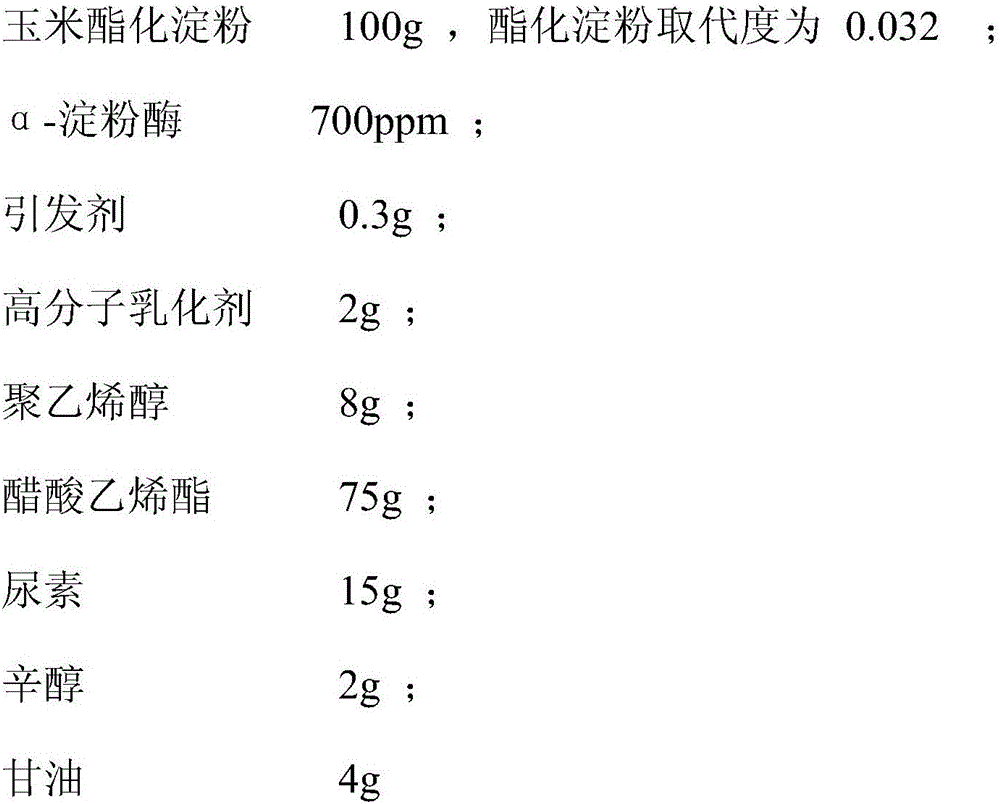

Embodiment 1

[0048]

[0049] 100g of corn esterified starch is added with water to make starch milk with a mass ratio of 30% (m / m) on a dry basis of starch, and 700ppm of α-amylase is added to the starch milk. After mixing evenly, the temperature of the system is adjusted to 85 ℃, keep warm for 15 minutes; adjust the temperature of the system to 95 ℃, keep warm for 10 minutes and then cool down to 70 ℃, adjust the pH value to 4.2 with 10% hydrochloric acid solution, add 0.3g of initiator in 5 batches, add 2g of polymer emulsifier, add 80g Pre-configured as a 10% (m / m) polyvinyl alcohol solution, then slowly add 75g of vinyl acetate dropwise in 5 times, the reaction time is 3h, adjust the pH to 6.5 with 5% sodium hydroxide solution, cool to 50°C, Add 15g of urea, 4g of glycerin and 2g of octanol, stir for 0.5h, then continue to cool down to 30°C, pack, seal and set aside.

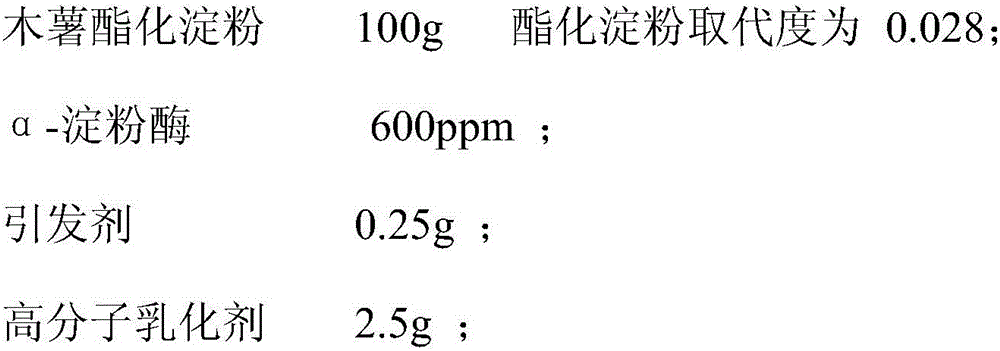

Embodiment 2

[0051]

[0052]

[0053]Add water to cassava esterified starch to make starch milk with a mass ratio of 32% (m / m) on a dry basis of starch, add 700ppm of α-amylase to the starch milk, mix well, and adjust the system temperature to 85°C , keep warm for 15 minutes, adjust the temperature of the system to 95°C, keep warm for 10 minutes, cool down to 70°C, adjust the pH value to 4.4 with 10% sulfuric acid solution, add 0.25g of compound initiator intermittently in 6 times, add 2.5g of polymer emulsifier, add 90g of polyvinyl alcohol solution pre-configured as 10% (m / m), then slowly add 80g of vinyl acetate dropwise in 6 times, the reaction time is 4h, adjust the pH to 7.0 with 5% sodium hydroxide solution, and cool down to 50°C , add 15g of urea, 5g of glycerin and 2.5g of octanol, stir for 0.5h and continue to cool down to 30°C, pack, seal and set aside.

Embodiment 3

[0055]

[0056] Add water to cassava esterified starch to make starch milk with a mass ratio of 35% (m / m) on a dry basis of starch, add 850ppm of α-amylase to the starch milk, mix well, adjust the system temperature to 80°C, and keep warm 15min, adjust the temperature of the system to 95°C, keep it warm for 10min, cool down to 70°C, adjust the pH value to 4.6 with 10% hydrochloric acid solution, add 0.5g of compound initiator intermittently in 5 times, add 4.0g of polymer emulsifier, add 100g of pre- Configure it as a 15% (m / m) polyvinyl alcohol solution, then slowly add 80 g of vinyl acetate dropwise in 5 times, the reaction time is 3.5 h, adjust the pH to 7.1 with 5% sodium hydroxide solution, cool to 50 ° C, Add 20g of urea, 5.0g of glycerin and 3.0g of octanol, stir for 0.5h, then continue to cool down to 30°C, pack, seal and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com