Preparation method of high oil-absorption material based on invasive plant

A technology of invasive plants and high oil absorption, applied in the direction of adsorption of water/sewage treatment, etc., can solve problems such as complex production equipment, achieve large oil absorption, easy to implement in production, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

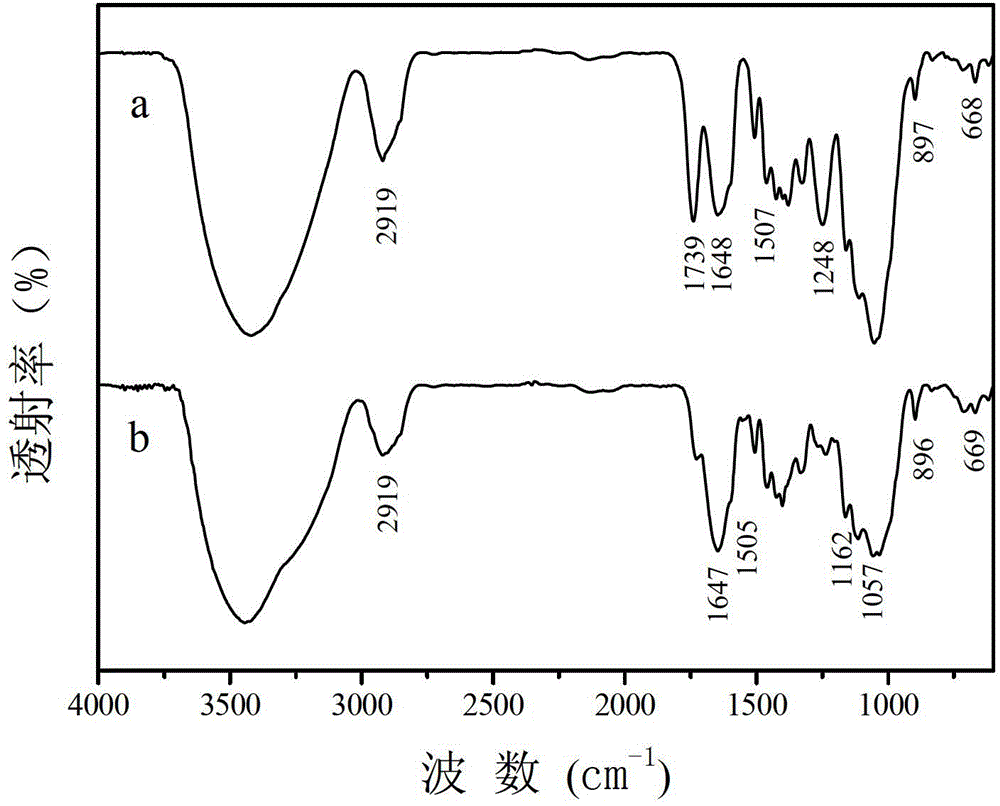

Image

Examples

Embodiment 1

[0026] The stalks of Solidago canadensis are pulverized with a micro-plant pulverizer to obtain plant powder. The plant powder was treated with 12% sodium hydroxide at 95°C for 30 minutes, washed until neutral, and dried in a vacuum oven at 60°C. Then add 95% ethanol solution to soak for 5 hours, dry and set aside.

[0027] The preparation of the solution is as follows: Dissolve 0.8g of dispersant gelatin in 70ml of distilled water, heat it at 80°C to dissolve it in water quickly; dissolve 0.15g of benzoyl peroxide in 5ml of toluene; dissolve 0.01g of hexadecane Trimethylammonium bromide was dissolved in 5ml of toluene.

[0028] Pour the prepared dispersant solution into a 500ml round bottom flask, add the pretreated cellulose, 15ml of methyl methacrylate and n-butyl methacrylate (MMA / BMA) mixed monomer, the prepared over Oxidize benzoyl and cetyltrimethylammonium bromide, use an ultrasonic cleaner to remove oxygen in the solution to mix evenly, and then under the action of ...

Embodiment 2

[0030] The stalks of Solidago canadensis are pulverized with a micro-plant pulverizer to obtain plant powder. The plant powder was treated with 12% sodium hydroxide at 95°C for 30 minutes, washed until neutral, and dried in a vacuum oven at 60°C. Then add 95% ethanol solution to soak for 5 hours, dry and set aside.

[0031] The preparation of the solution is as follows: Dissolve 1.5g dispersant gelatin in 70ml distilled water, heat it at 80°C to dissolve it in water quickly; dissolve 0.75g benzoyl peroxide in 5ml toluene; dissolve 0.065g hexadecane Trimethylammonium bromide was dissolved in 5ml of toluene.

[0032] Pour the configured dispersant solution into a 500ml round-bottomed flask, add the pretreated cellulose, 30ml methyl methacrylate and n-butyl methacrylate (MMA / BMA) mixed monomer, the configured over Oxidize benzoyl and cetyltrimethylammonium bromide, use an ultrasonic cleaner to remove oxygen in the solution to mix evenly, and then under the action of a magnetic ...

Embodiment 3

[0034] The stalks of Solidago canadensis are pulverized with a micro-plant pulverizer to obtain plant powder. The plant powder was treated with 12% sodium hydroxide at 95°C for 30 minutes, washed until neutral, and dried in a vacuum oven at 60°C. Then add 95% ethanol solution to soak for 5 hours, dry and set aside.

[0035] The preparation of the solution is as follows: Dissolve 1.2g of dispersant gelatin in 70ml of distilled water, heat it at 80°C to dissolve it in water quickly; dissolve 0.5g of benzoyl peroxide in 5ml of toluene; dissolve 0.01g of hexadecane Trimethylammonium bromide was dissolved in 5ml of toluene.

[0036]Pour the prepared dispersant solution into a 500ml round bottom flask, add the pretreated cellulose, 17.5ml of methyl methacrylate and n-butyl methacrylate (MMA / BMA) mixed monomers, and the prepared Benzoyl peroxide and cetyltrimethylammonium bromide, use an ultrasonic cleaner to remove oxygen in the solution to mix evenly, and then under the action of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com